Combined heating and hot water boiler, and control method therefor

A control method and technology for hot water, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of aggravating temperature deviation, increasing hot water temperature deviation, and slowing hot water temperature change speed, etc. Achieve the effect of reducing maintenance costs, preventing life shortening, and minimizing deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, configurations and functions of preferred embodiments of the present invention will be described with reference to the drawings.

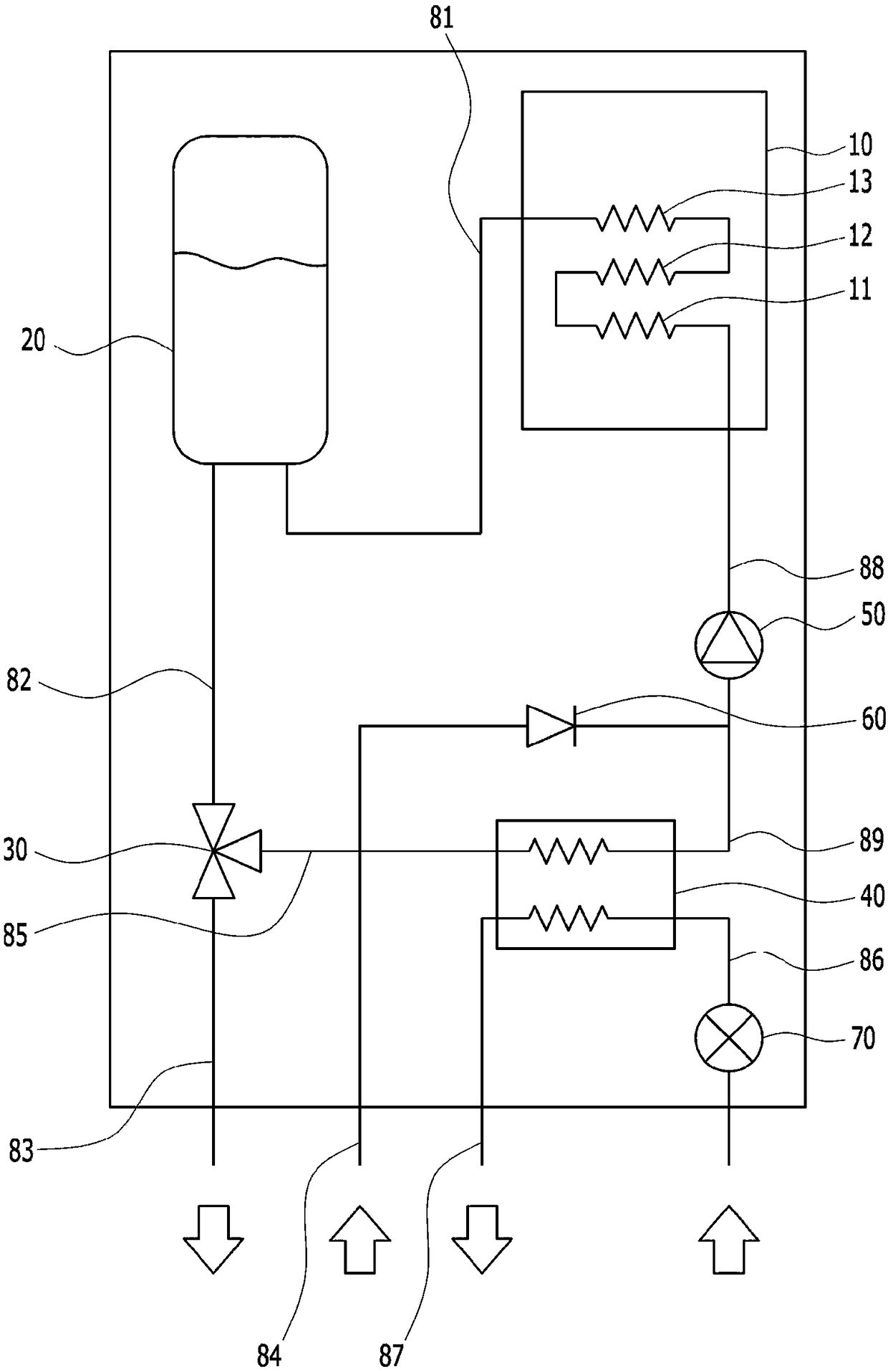

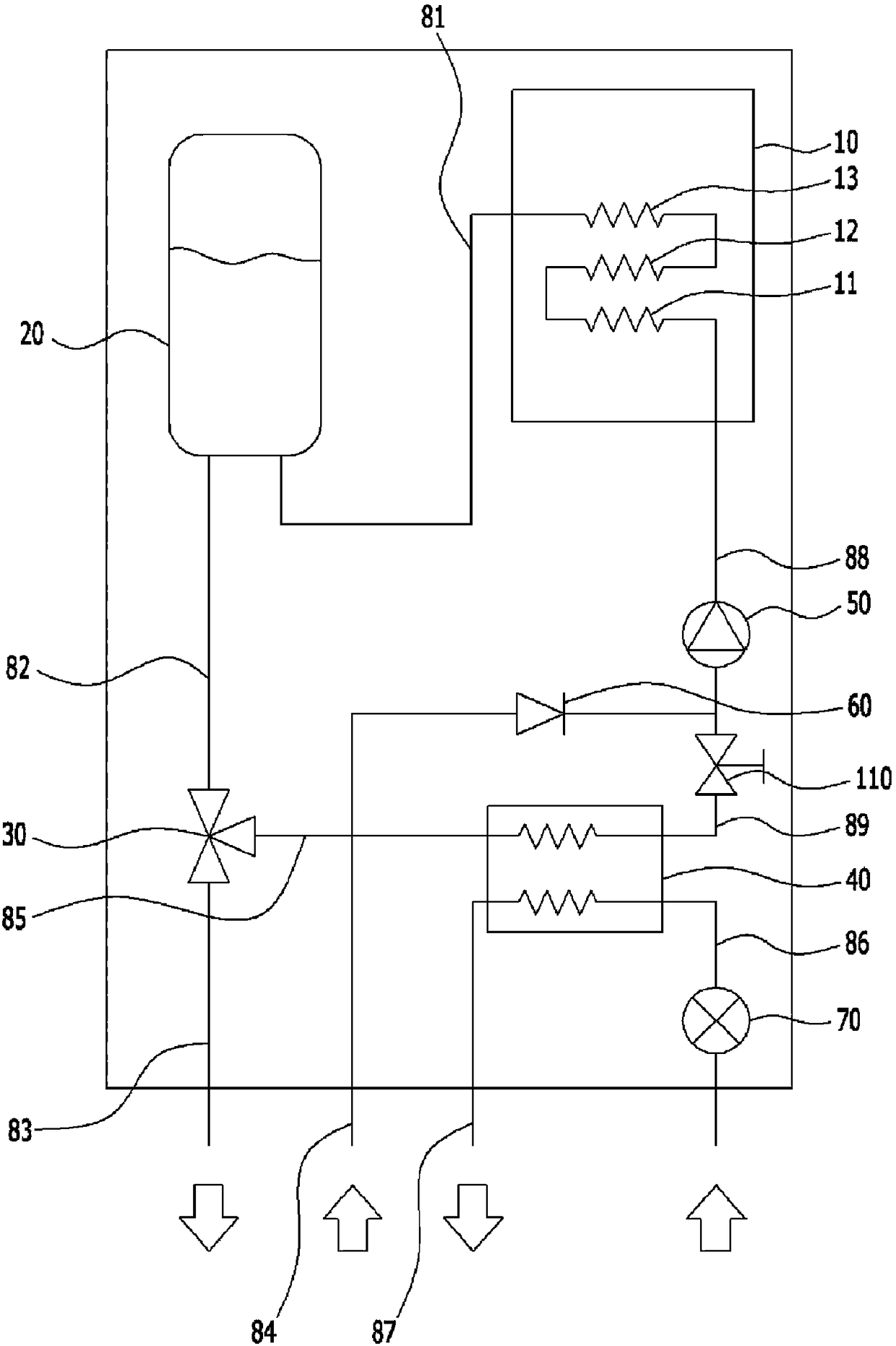

[0048] refer to figure 2 Next, the configuration of the heating and hot water boiler according to the present invention will be described.

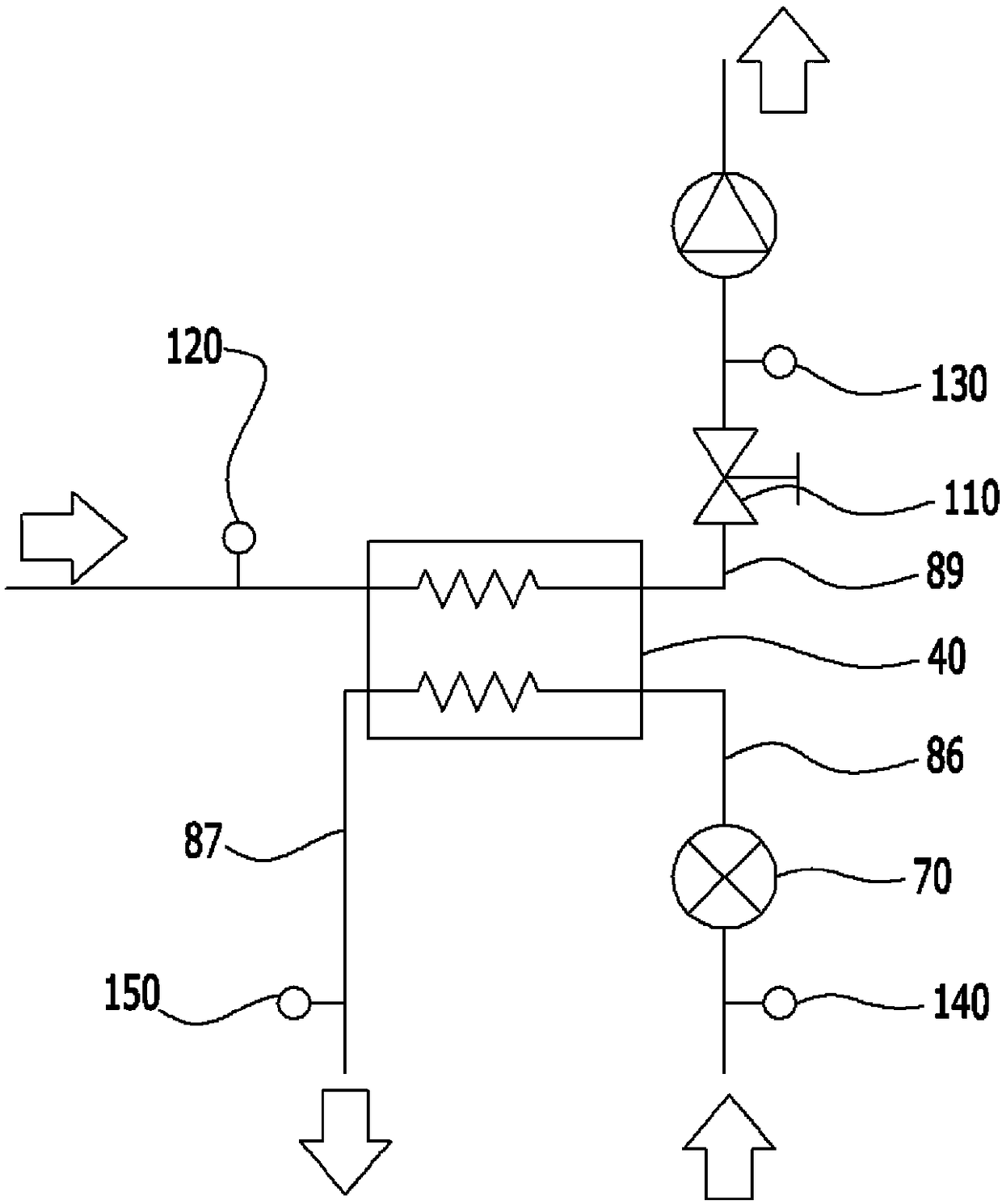

[0049] The heating and hot water boiler according to the present invention includes: a first heat exchanger 10 for generating high-temperature supply water; a second heat exchanger 40 for passing between the supply water supplied by the first heat exchanger 10 and the direct supply water; heat exchange to generate hot water; the flow adjustment valve 110 is used to adjust the flow rate of the supply water supplied to the second heat exchanger 40 in the hot water mode; the control part is used to adjust the flow rate of the flow adjustment valve 110 opening.

[0050] The first heat exchanger 10 is provided with a flow path through which supply water flows and a heating unit for heating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com