Electromagnetic attraction forming device and method

An attractive and electromagnetic technology, applied in the field of metal forming manufacturing, can solve the problems of high manufacturing cost, complex coil structure, low service life, etc., and achieve the effect of widening the forming process window and simple forming control requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

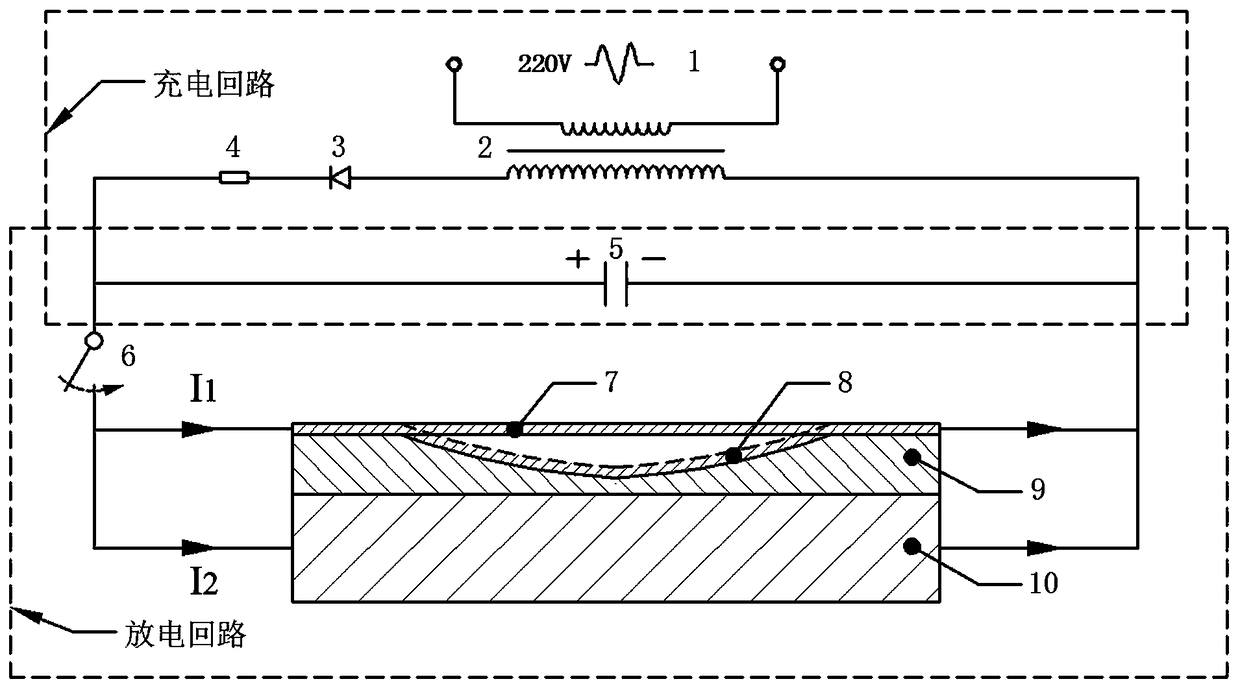

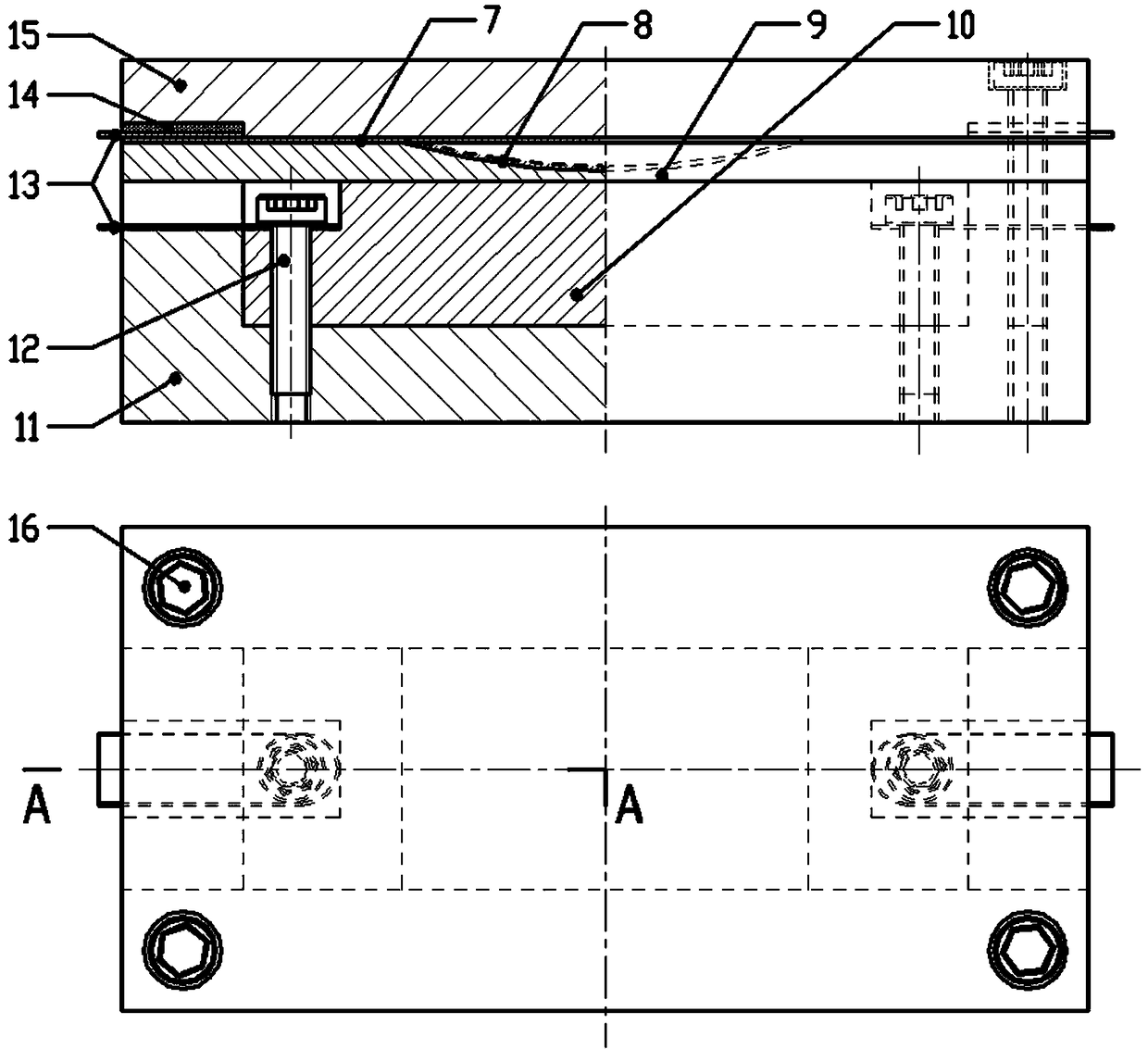

[0033] Please refer to Figure 1 to Figure 2 It is an electromagnetic attraction forming device, including a discharge power supply system, a metal piece to be formed 7, a die 9, a driving plate 10, and positioning and pressing components. The discharge power supply system is respectively connected to the metal part 7 to be formed and the drive plate 10 through wires 13, the die 9 is placed between the metal part 7 to be formed and the drive plate 10, and the side of the die 9 forming the contour of the workpiece is close to the shape of the workpiece to be formed. Formed metal parts 7. The forming device is also equipped with corresponding positioning and pressing components: a base 11 , a pressing plate 12 , a rubber gasket 14 , a wire pressing screw 12 and a pressing plate pressing screw 16 . The base 11 serves as the base of the entire device, and a cavity corresponding to the shape of the driving board 10 is opened in the middle for placing the driving board 10 . The dr...

Embodiment 2

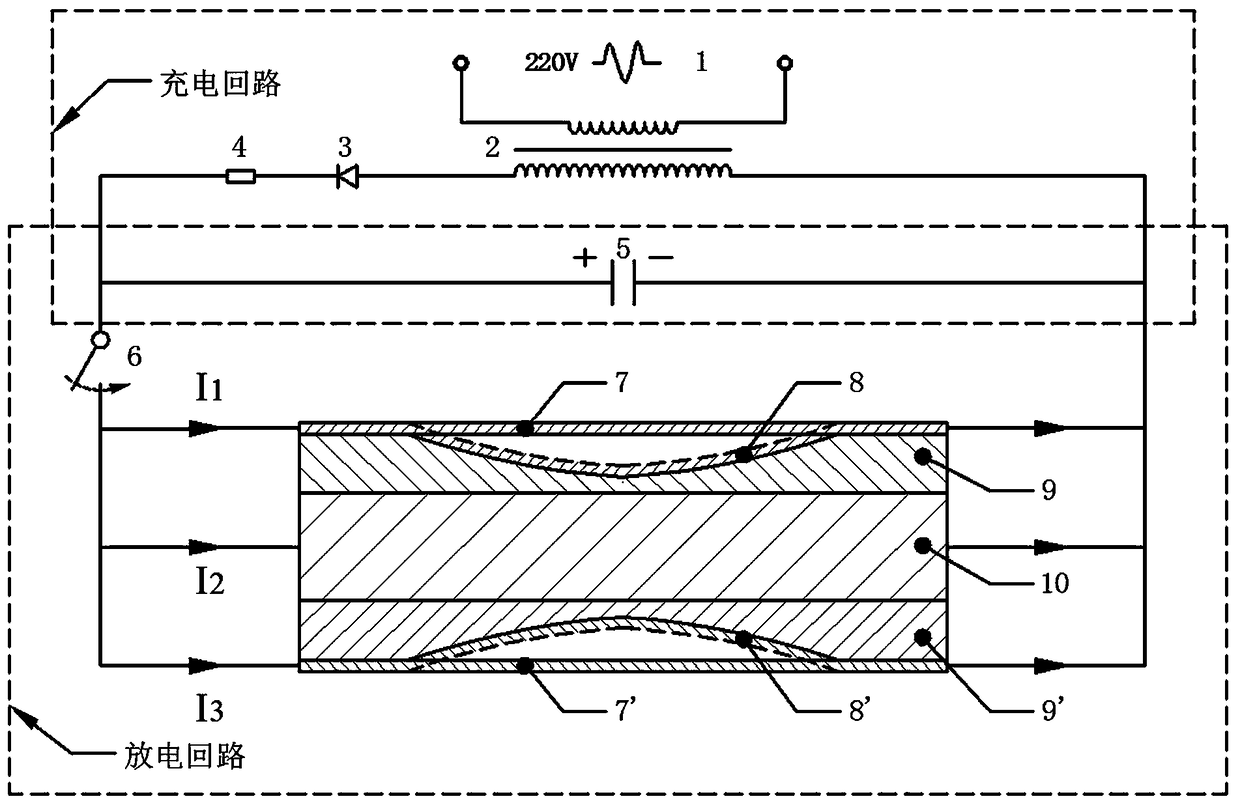

[0046] Refer to as image 3 The electromagnetic attraction forming device shown is different from the device in Embodiment 1 in that a set of second concave molds symmetrical to the concave mold 9 and the metal piece 7 to be formed is set on the side of the drive plate base instead. 9' and the second metal piece 7' to be formed, and apply current to the metal pieces 7 and 7' to be formed on both sides and the driving plate 10 to form two metal plates at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com