Shear mechanism for cutting spiral coil and then bending countersink head

A technology of helical coil and scissors mechanism, applied in the field of scissors mechanism, can solve the problems of irregularity of metal wires, influence on appearance, irregularity, etc., and achieve the effects of ensuring specification and stability, ingenious and reasonable structure design, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

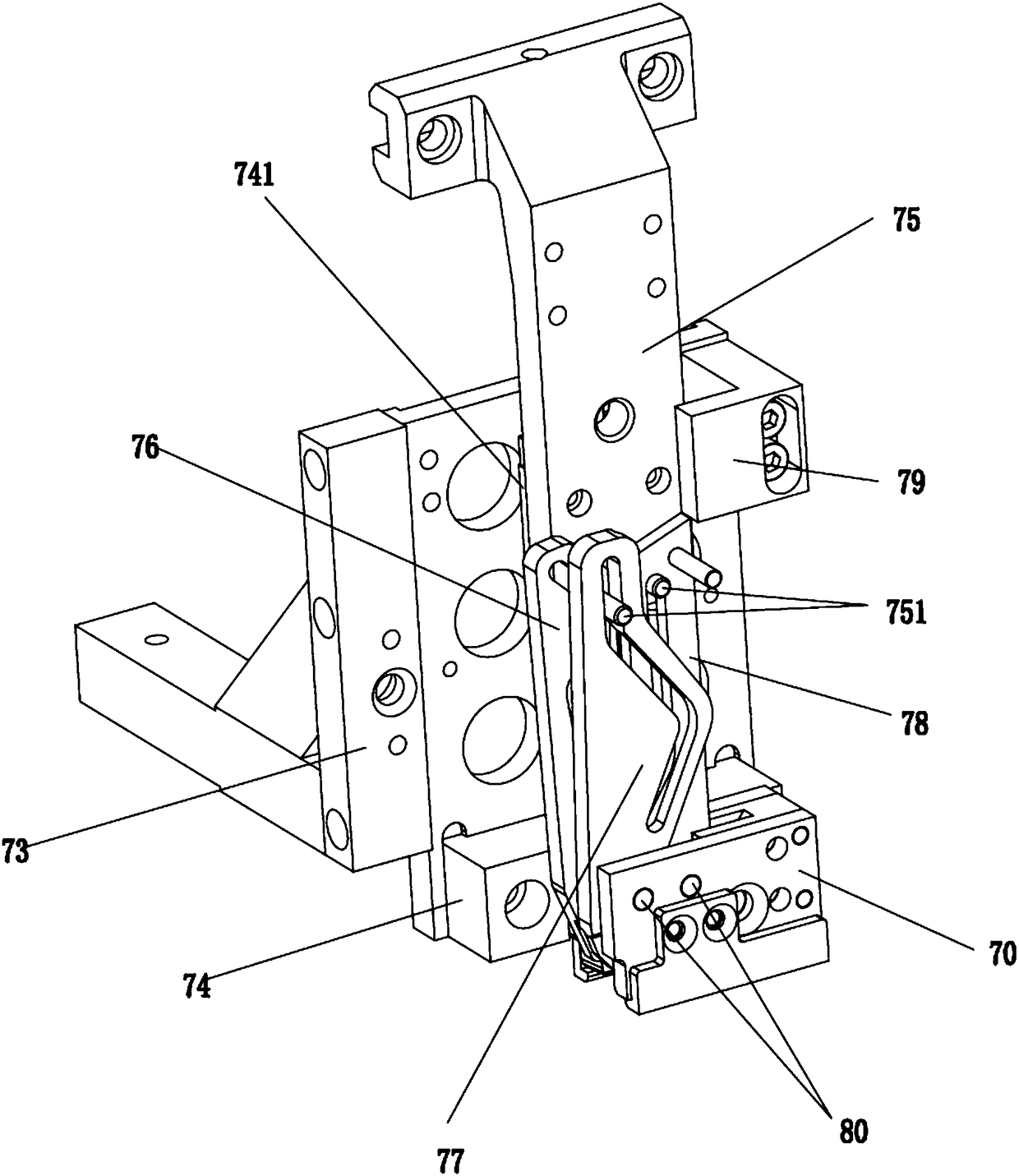

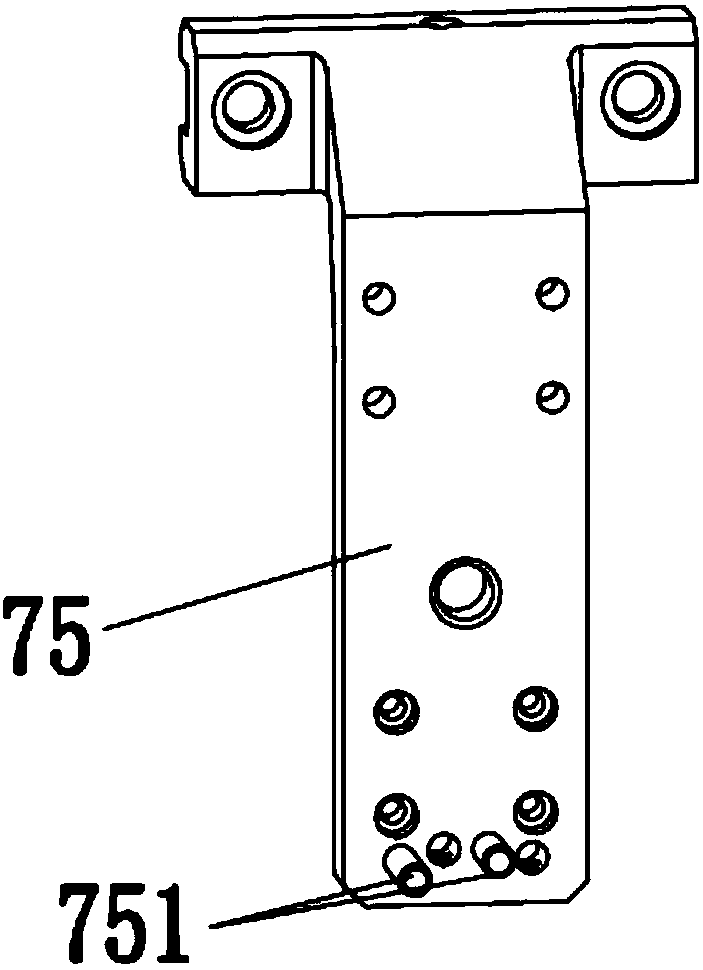

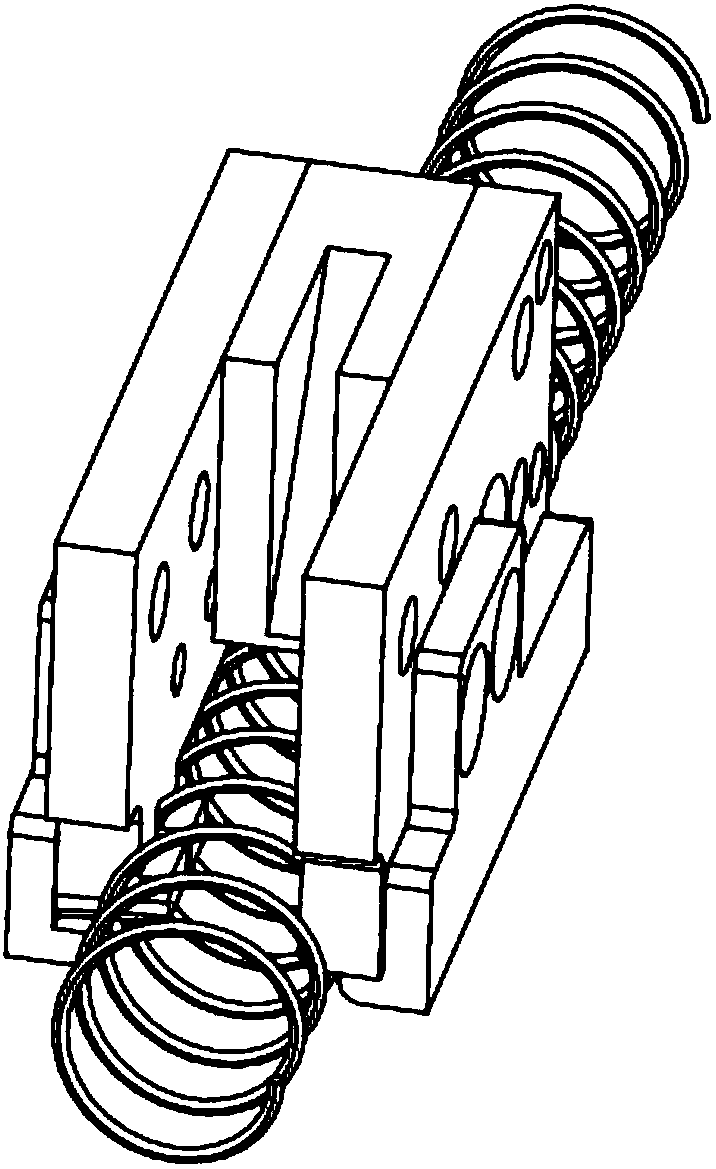

[0033] Such as Figure 1-Figure 7 As shown, the scissors mechanism described in this embodiment to cut the helical coil and bend the hidden head includes an L-shaped fixed plate 74, and a slide rail 741 is fixed on the front side of the transverse part of the L-shaped fixed plate 74, and the L-shaped fixed plate The outside of the longitudinal part of the plate 74 is fixed with a spiral coil positioning frame 70; The side is provided with the alveolus 706 for the corresponding embedded positioning of the spiral coil; the slider of the slide rail 741 is fixed with a connecting arm 75, and the connecting arm 75 is equipped with a shearing knife group that bends the hidden head after cutting the spiral coil; The bottom of the knife set is inserted into the working groove, and after working, the helical coil is cut and the hidden head is bent;

[0034]In the present embodiment, the specific structure of the installation of the shearing knife group is: the shearing knife group inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com