Special fixture for turning of thin cylindrical parts and operation method thereof

A technology of special fixtures and cylindrical parts, applied in the direction of expanding mandrels, etc., can solve problems such as affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The foregoing descriptions are only preferred embodiments of the present invention, and all equivalent changes and modifications made in accordance with the scope of the patent application of the present invention should fall within the scope of the present invention.

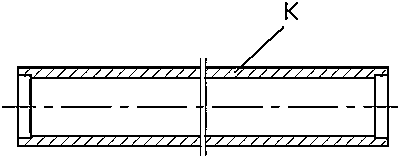

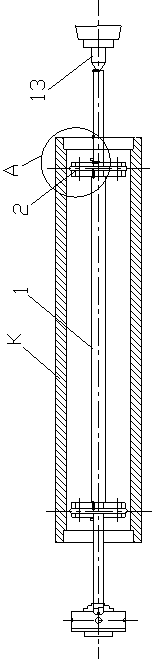

[0017] The special fixture for turning thin cylindrical parts of the present invention includes a mandrel 1 clamped on a three-jaw fixture and an expandable support plate 2 fixedly sleeved on both ends of the mandrel.

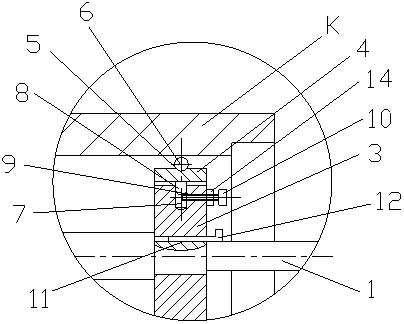

[0018] Further, for reasonable design, the support plate 2 includes an inner disc 3 sleeved on the stepped shaft end of the spindle, and an annular carriage 4 is sleeved on the periphery of the inner disc, and the outer peripheral surface of the annular carriage 4 is provided with The annular groove 5 is sleeved with a wire ring 6 against the inner wall surface of the workpiece, and the inner disc 3 is provided with a plurality of counterbore grooves 7 on the outer peripheral wall surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com