A four-point clamping fixture

A technology for clamping fixtures and fixture seats, which is applied in the direction of clamping, manufacturing tools, supports, etc., can solve problems such as changes, flatness errors, and thin-walled die-casting parts with inaccurate shapes, so as to eliminate clamping Effects of deformation and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

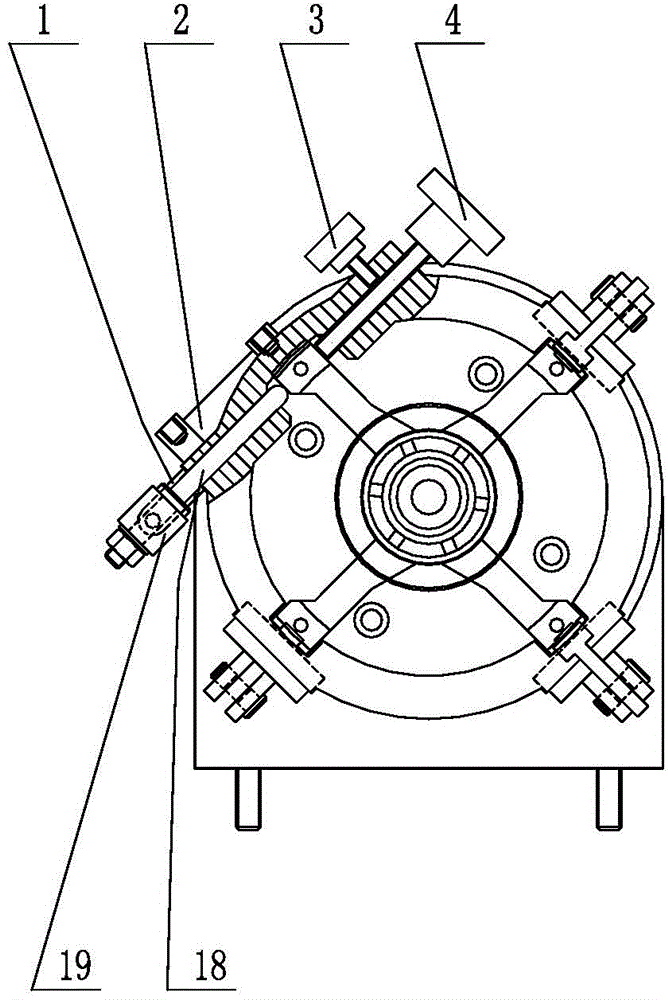

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

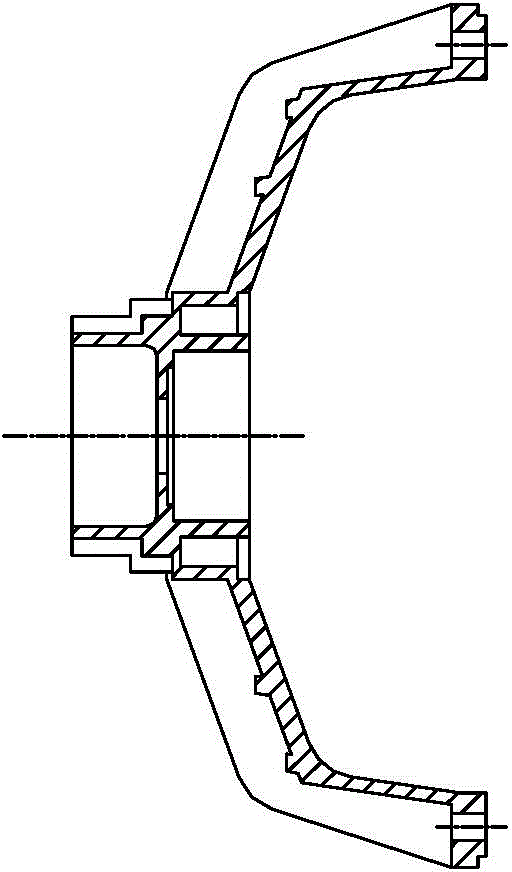

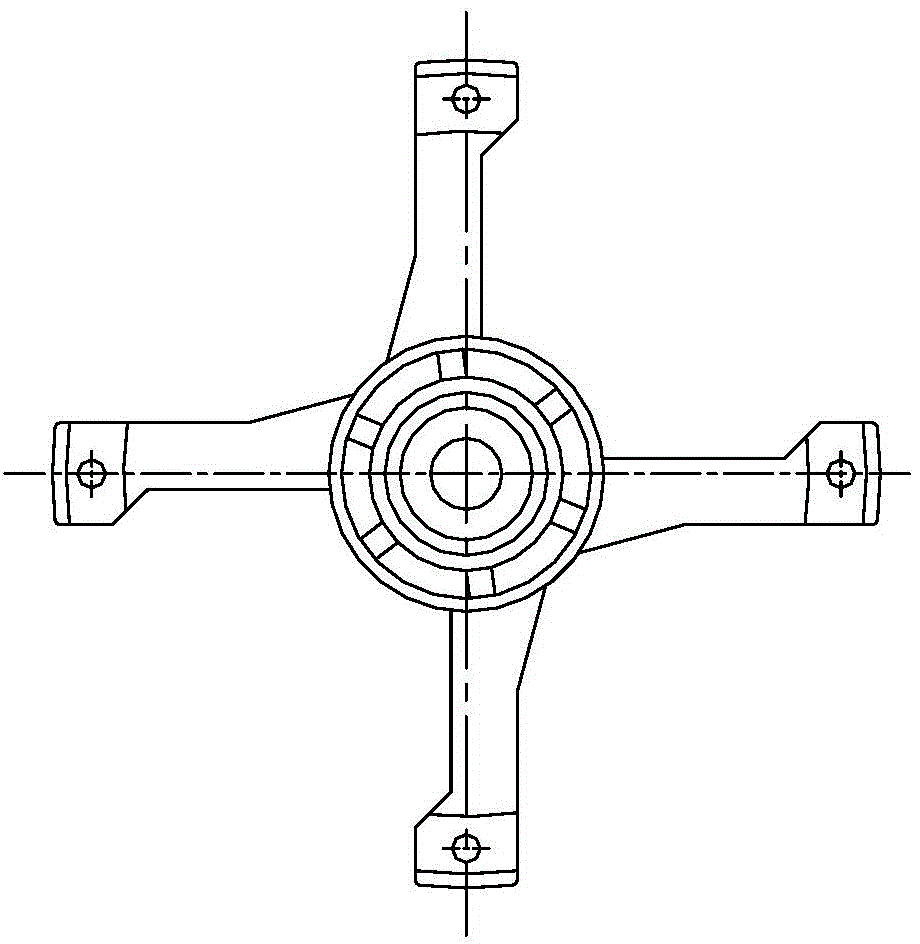

[0020] Such as image 3 and Figure 4 As shown, a four-point clamping fixture of the present invention includes a fixture seat 5, a positioning plate 12, a positioning sleeve 16 and multiple sets of end surface clamping devices. The disc 12 is mounted on the surface of the fixture seat 5 by screws. The end surface clamping device includes a piston rod 7, a pin shaft 8, an end face bracket 9, a pin 11 and a swing rod 10. The piston rod 7 is installed in the hole of the end face oil cylinder 6, and the piston rod 7 and the swing rod 10 are connected through the pin shaft 8, and the swing rod 7 The rod 10 rotates around the pin 11, clamps the workpiece 13 through the top of the swing rod 10 and the positioning disc 12, the pin 11 is fixed on the end support 9, the positioning disc 12 is installed on the fixture seat 5 through the positioning sleeve 16, and is fixed by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com