Silicon chip edge protection apparatus with self-locking gripper

A silicon chip edge protection and gripper device technology, which is applied in the field of integrated circuit manufacturing equipment, can solve the problems of large manufacturing errors, deformation of the protection ring, and poor workmanship, and achieve easy processing and manufacturing, elimination of clamping deformation, and good self-centering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

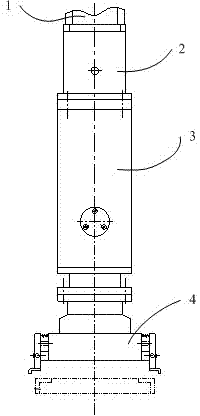

[0021] like figure 1 As shown, the silicon chip edge protection device with self-locking gripper of the present invention is composed of a servo motor 1 , a reduction mechanism 2 , a vertical movement mechanism 3 and a gripper device 4 . The servo motor 1 is controlled by the control system, drives the vertical motion mechanism 3 through the reduction mechanism 2, and changes the rotational motion of the motor into a linear motion, thereby carrying the gripper device 4 to the predetermined transfer position, and placing the edge protection ring on the silicon A series of automated tasks on the wafer, grabbing the edge protection ring and leaving the wafer.

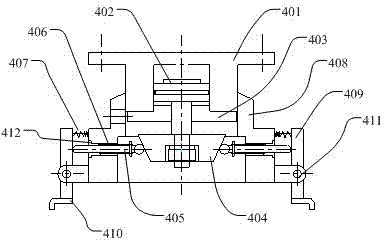

[0022] The gripper device 4 of the gripper self-locking silicon chip edge protection device of the present invention is as figure 2 As shown, it is mainly composed of cylinder block 401...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com