Processing method for double-layered separating wall kind-part hole and assembly clamp of double-layered separating wall kind-part

A technology of double-layer partitions and processing methods, which is applied to manufacturing tools, metal processing equipment, metal processing machinery parts, etc. The effect of clip deformation, stable product quality and reduction of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

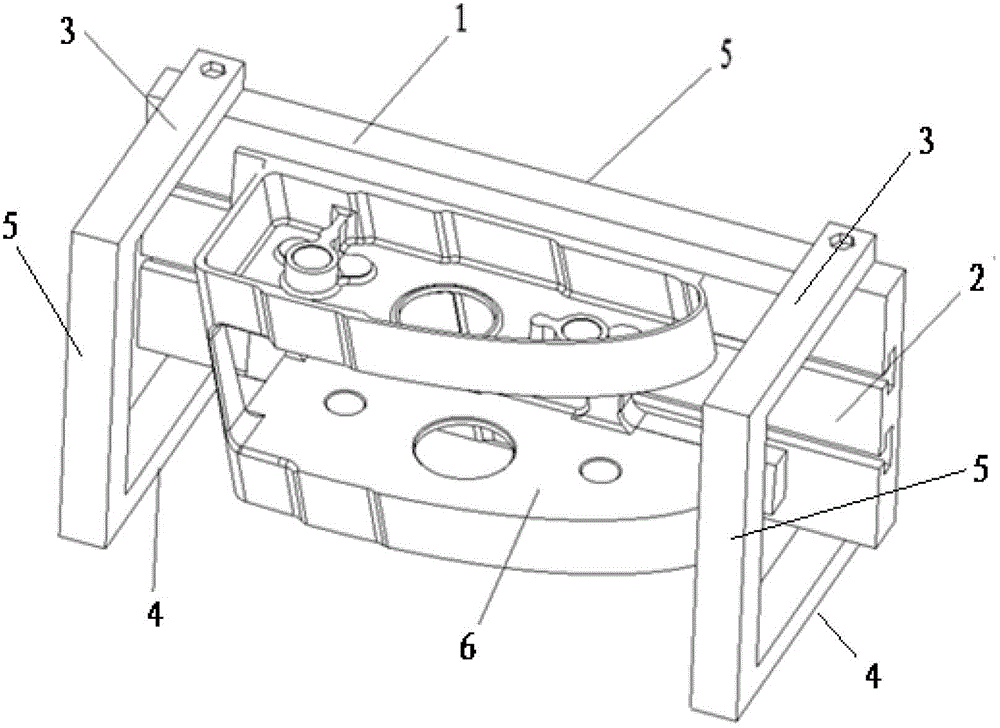

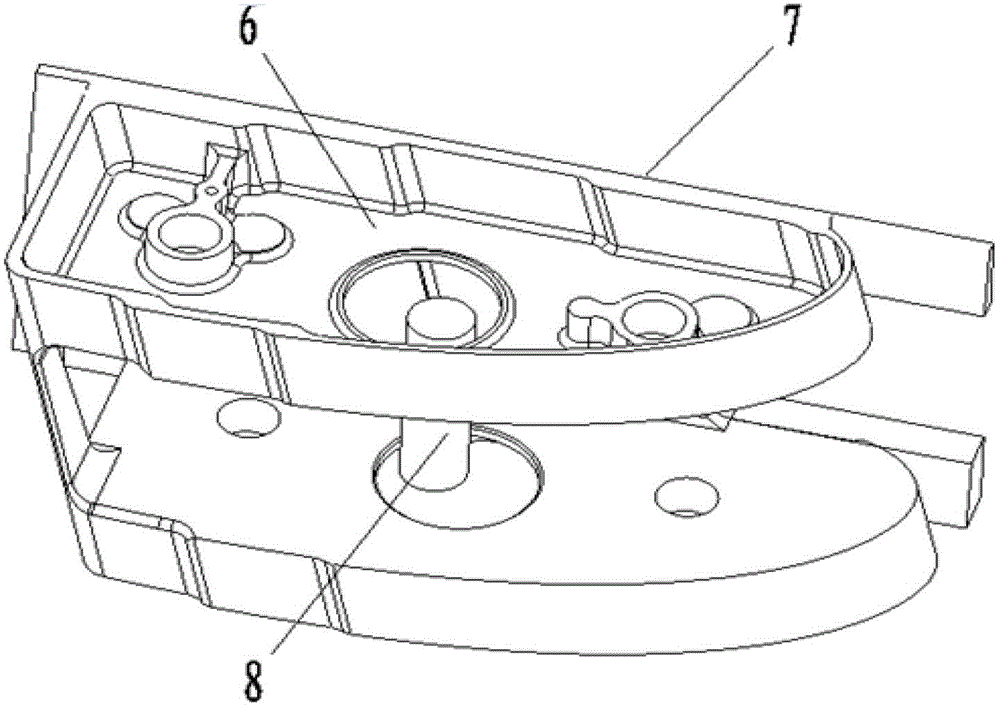

[0018] Figure 1 is a schematic diagram of the clamping of a double-layer clapboard part 6 with assembly fixture 1. The assembly fixture is a frame structure consisting of an assembly side plate 2 and two identical assembly frames 5. The assembly side plate is a regular Square flat plate, the inner side of the flat plate is the clamping surface for clamping parts, the height of the assembled side plate is higher than the height of the parts, and the assembled frame 5 is two high-precision machining parts. After assembling, the two assembled frames 5 The outer surfaces of the two outer surfaces are on the same plane, and the two outer surfaces are positioning surfaces parallel to each other, that is, the first positioning surface 3 shown in the figure and the second positioning surface 4 on the other side are parallel to each other. The outer surface of a double-layer partition part 6 is used as the part reference plane 7 for clamping the part, and it is positioned and clamped on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com