Connector plug-in machine of liquid crystal display

A technology for LCD screens and connectors, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as decreased vision of workers, damage to power sockets, and increase in defective products, so as to avoid visual damage, reduce labor intensity, and reduce labor intensity. The effect of reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

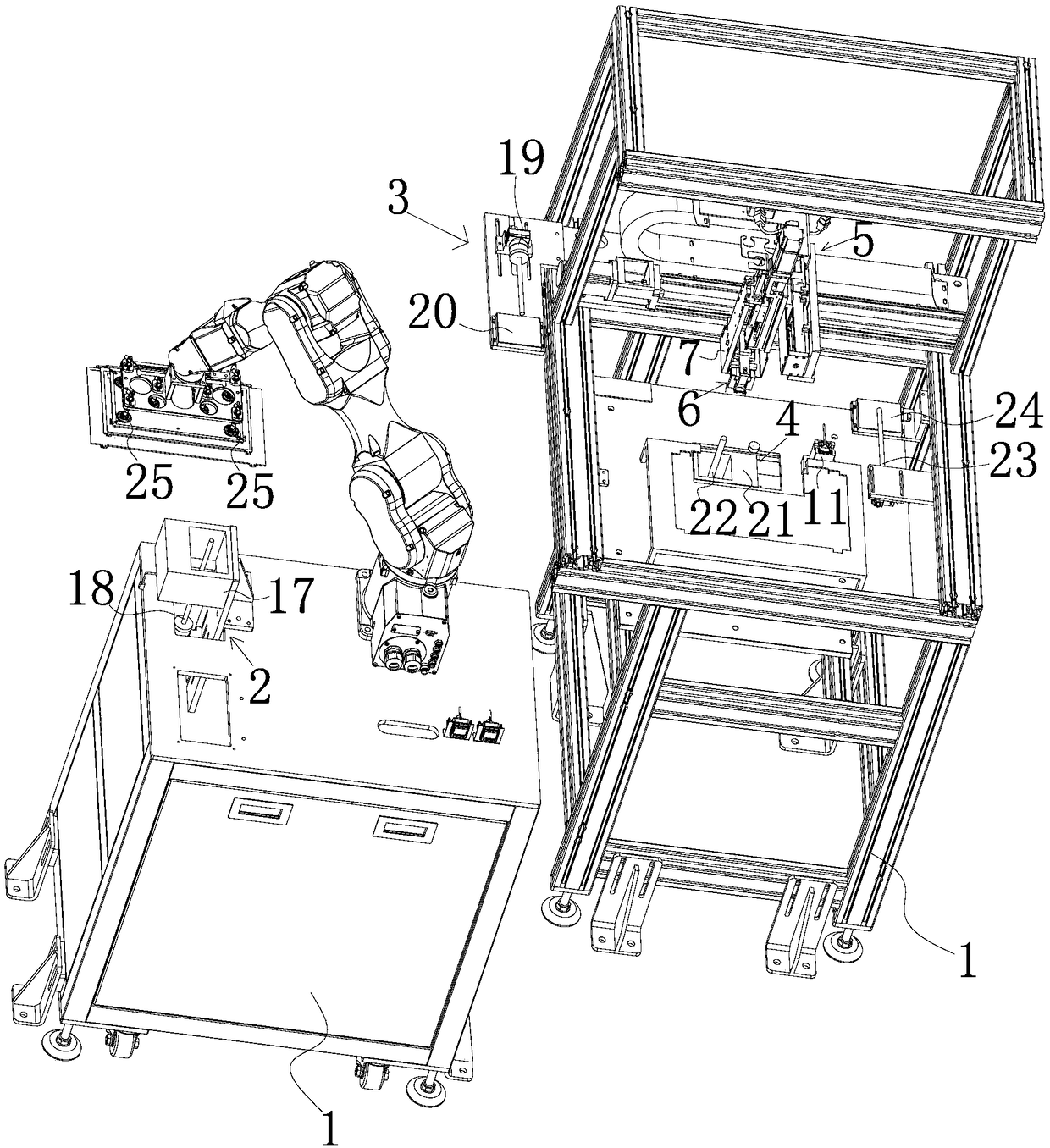

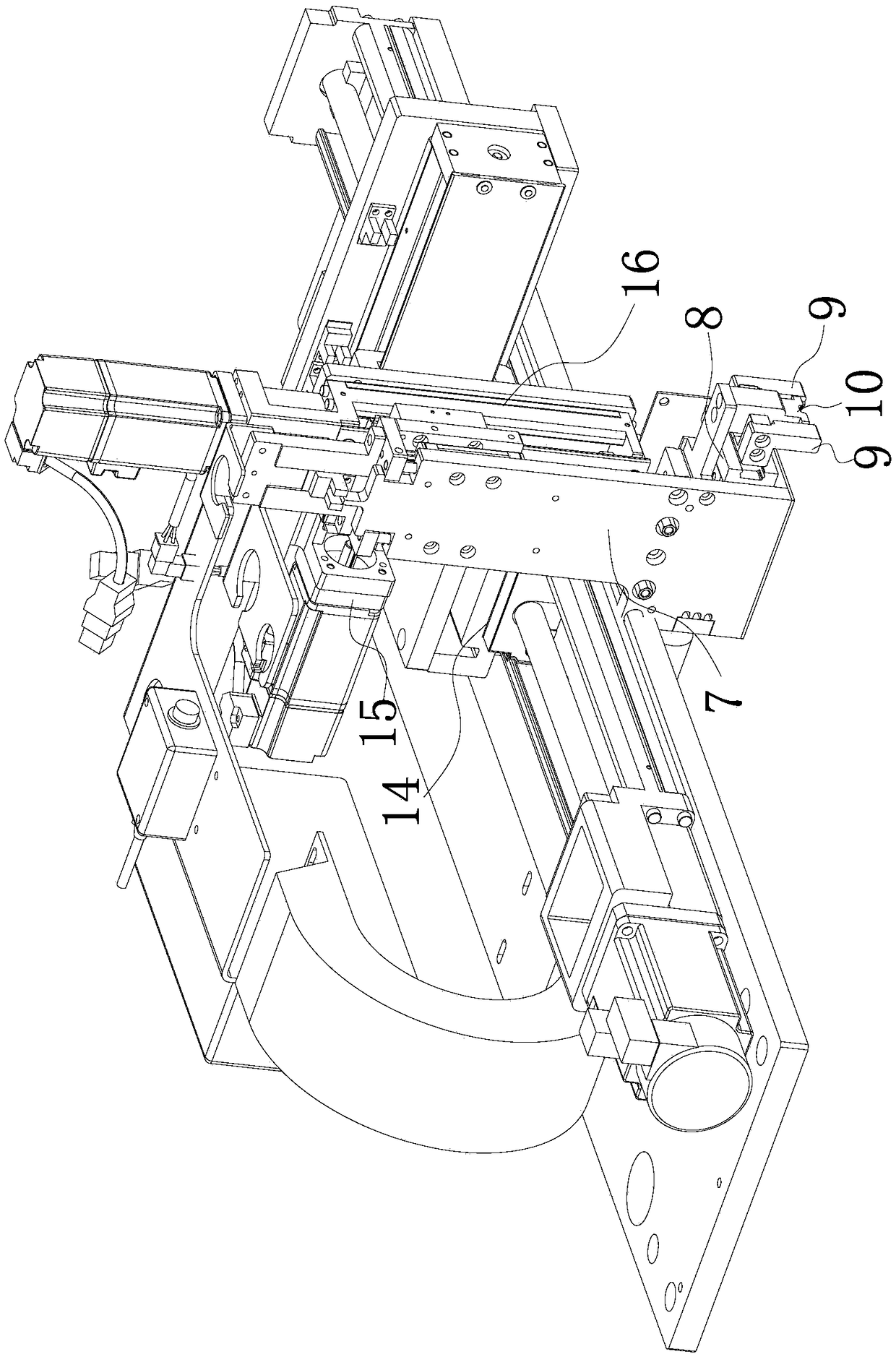

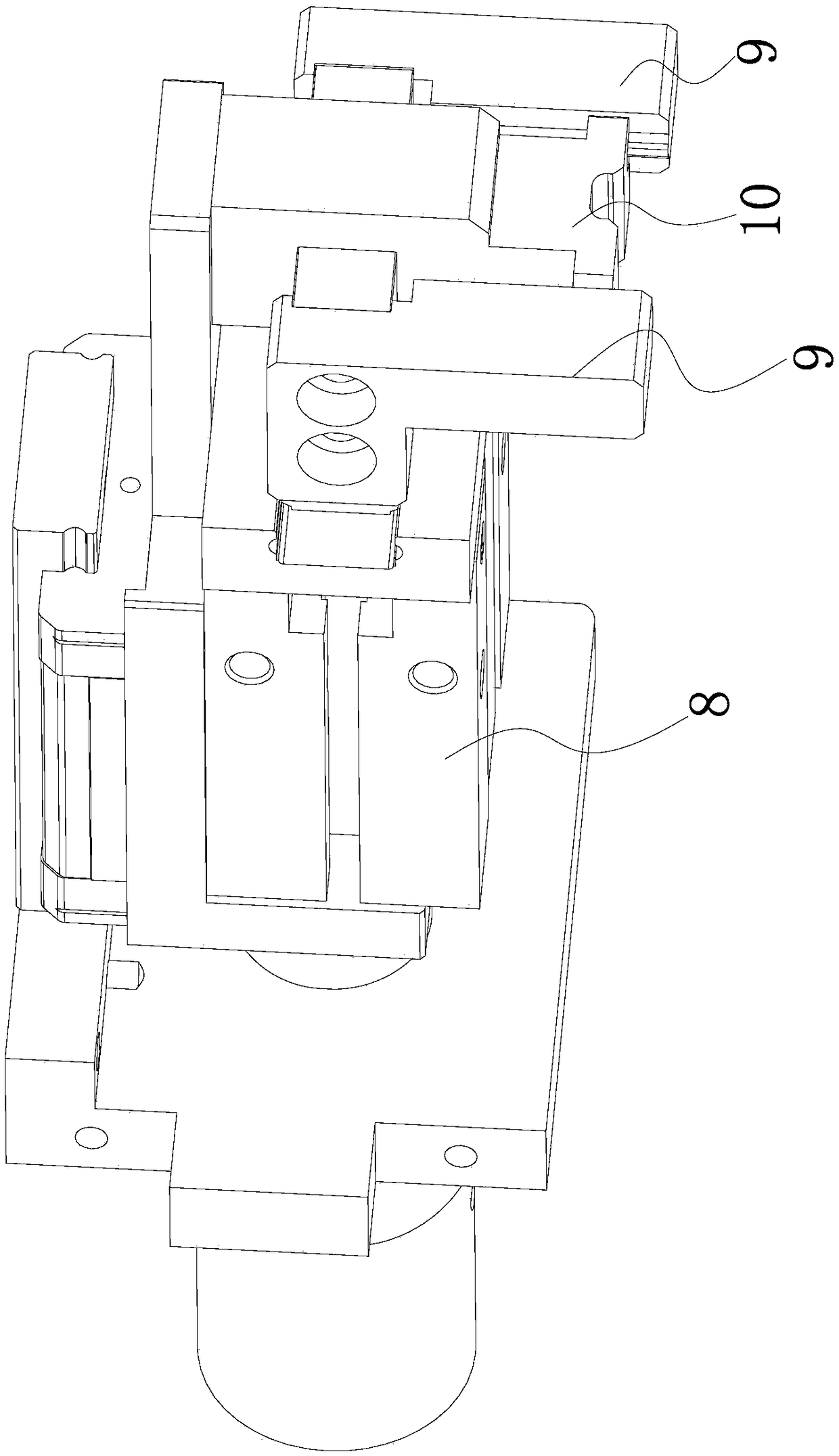

[0051] Such as figure 1 As shown, the LCD screen connector mating machine includes: a fixed frame 1; a liquid crystal screen grasping component, which is arranged on the fixed frame 1, and the liquid crystal screen grasping component is used to grasp and move the liquid crystal screen; The liquid crystal screen positioning component is arranged on the fixed frame 1, and the liquid crystal screen positioning component is used to obtain the position information of the liquid crystal screen and makes the liquid crystal screen grasping component make corresponding adjustments; the connector grasping component is set On the fixed frame 1, the connector grabbing component is used to grab and drive the connector to move; the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com