AGV vehicle handling robot

A technology for handling robots and cars, applied in the field of AGV car handling robots, can solve the problems that ordinary parking lots are difficult to popularize and use, the machining of Mecanum wheels is difficult, and it is impossible to realize autonomous machining. The effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

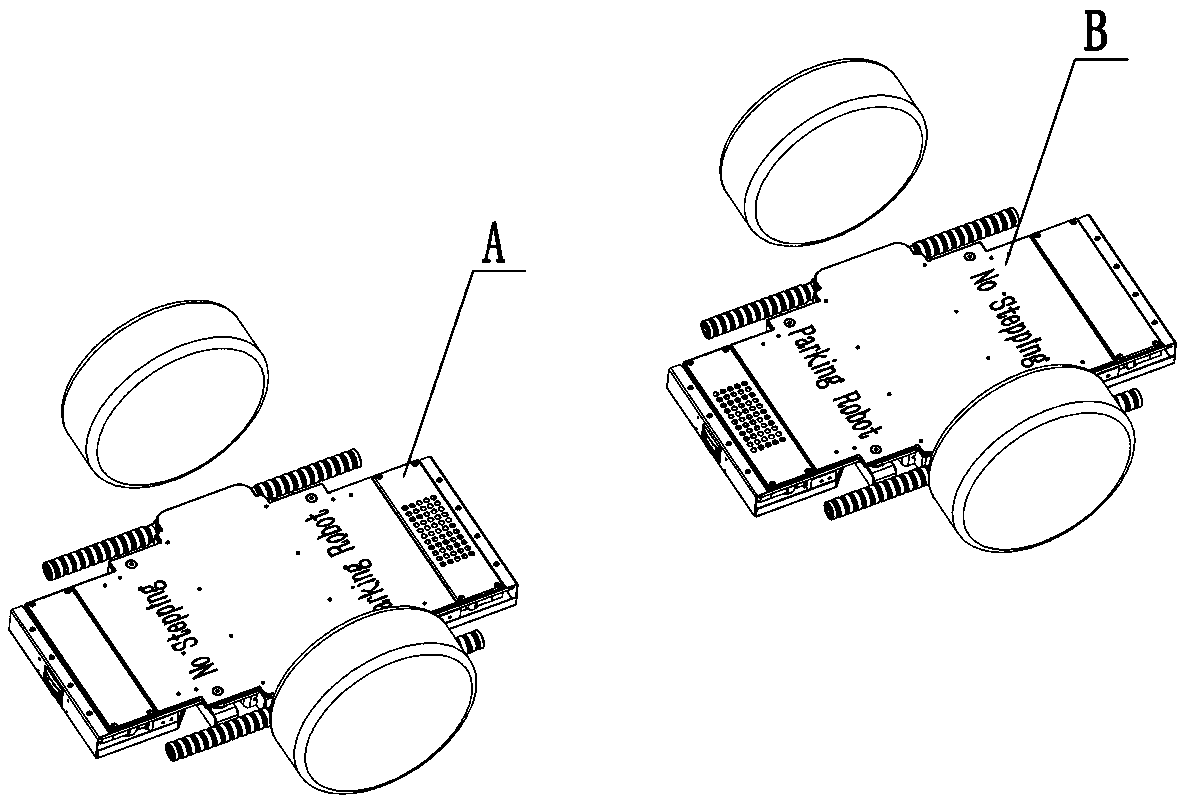

[0032] An AGV vehicle handling robot includes a first AGV body A and a second AGV body B. Such as figure 1 As shown, the transported vehicle in the figure is represented by 4 tires instead, and the first AGV body A and the second AGV body B can be transferred under the vehicle chassis to carry the vehicle.

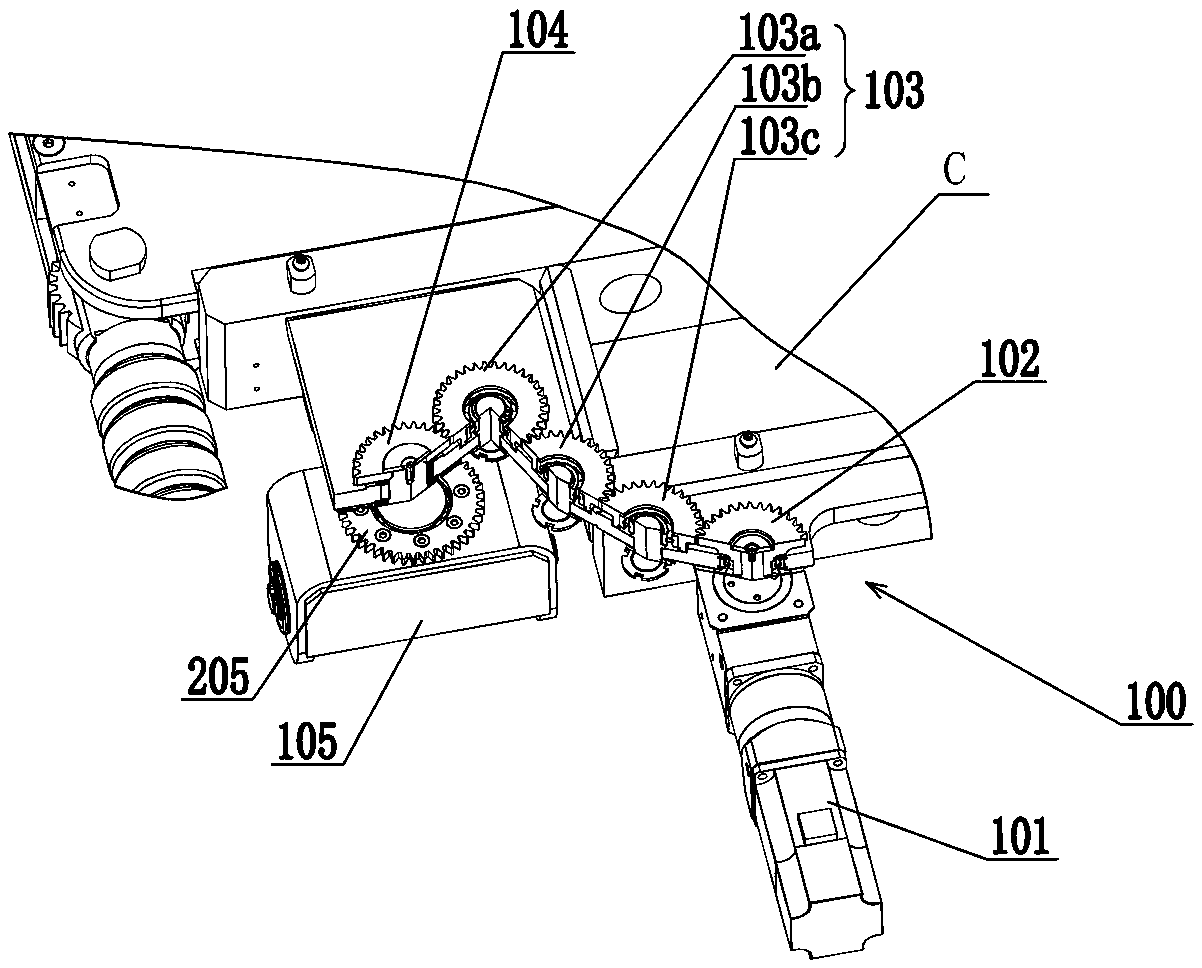

[0033] Both the first AGV body A and the second AGV body B include a traveling mechanism 100 , a steering mechanism 200 and a clamping mechanism 300 .

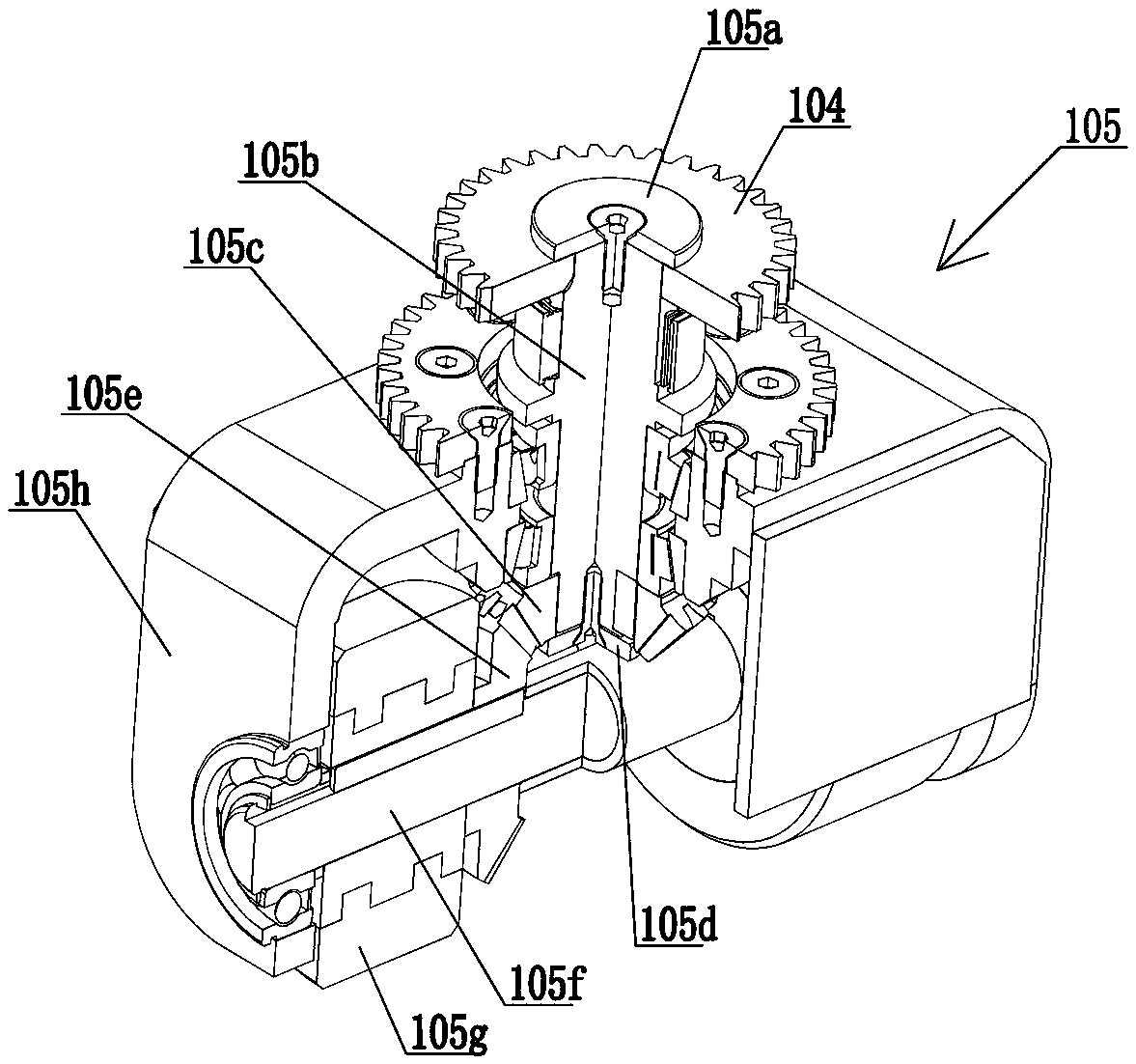

[0034] The traveling mechanism 100 includes a traveling driving motor 101 , a traveling motor driving gear 102 , a traveling linkage gear set 103 , a traveling transmission gear 104 , and a traveling wheel set 105 .

[0035] The traveling driving motor 101 is fixedly mounted on the trolley frame C, and is used for providing traveling power for the traveling wheel set. The trolley frame C is the frame b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com