Weight dividing control system for blocky foods

A control system and food technology, applied in the field of automation, can solve the problems of low efficiency, achieve the effect of ensuring high efficiency, saving monitoring time, and avoiding overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

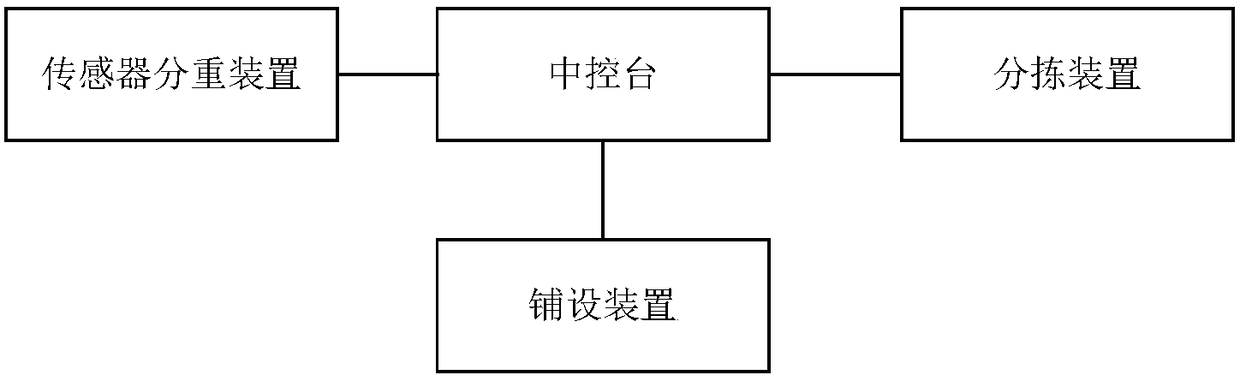

[0028] see figure 1 , providing a weight control system for block food, including: a center console and a sensor weighing device connected thereto, a laying device and a sorting device;

[0029] The laying device is used to spread the cut but unseparated block food on the sensor weighing device at a preset distance;

[0030] The sensor weighing device is used to weigh each block of food after the tiling operation and upload its gravity value to the center console;

[0031] The center console is used to set the gravity value interval, and classify the gravity value of each block food received into different gravity value intervals, and control the The senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com