Thermoplastic resin coated water-borne epoxy resin cement concrete crack self-repairing microcapsule and preparation method thereof

A water-based epoxy resin, self-healing microcapsule technology, applied in the field of concrete, can solve the problems of difficult rupture of the capsule wall, high capsule wall strength, and inability to release the internal repair agent, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

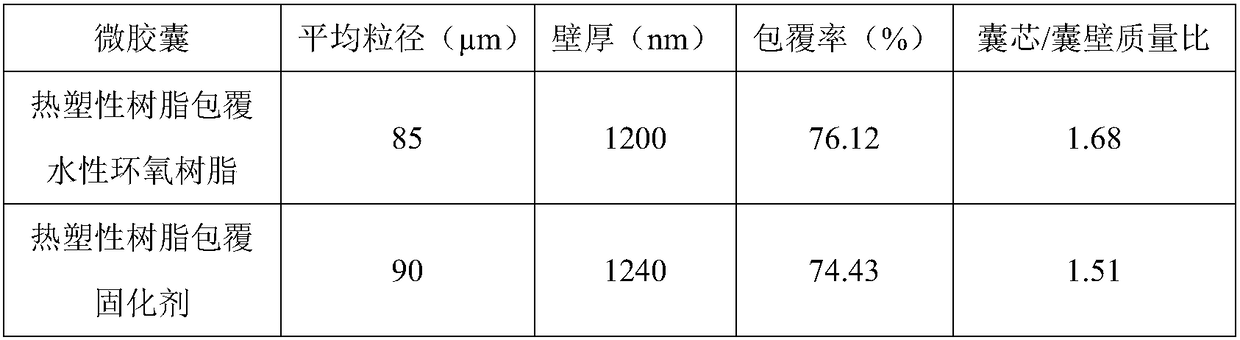

Embodiment 1

[0030] A thermoplastic resin-coated water-based epoxy resin type cement concrete crack self-repairing microcapsule, prepared as follows:

[0031] (1) Preparation of water-based epoxy resin microcapsules:

[0032] a. Take by weighing 30 parts of paraffin wax (melting point is 58~60 ℃), 5 parts of C9 petroleum resin, 65 parts of waterborne epoxy resin (solid content 48%);

[0033] b. Mix 30 parts of paraffin and 20 parts of perfluorotributylamine, heat to 70°C, and stir at 400-600rpm for 30 minutes to melt and disperse the paraffin in the perfluorotributylamine solution to obtain paraffin / perfluorotributylamine Amine mixture;

[0034] c. Add 5 parts of petroleum resin into a three-necked flask with a heating mantle, heat to 130-140°C, stir at a speed of 400-600rpm for 15 minutes, then add the above paraffin / perfluorotributylamine mixture into the three-necked flask, Control the temperature at 85°C and stir for 15 minutes; then add 65 parts of water-based epoxy resin into the t...

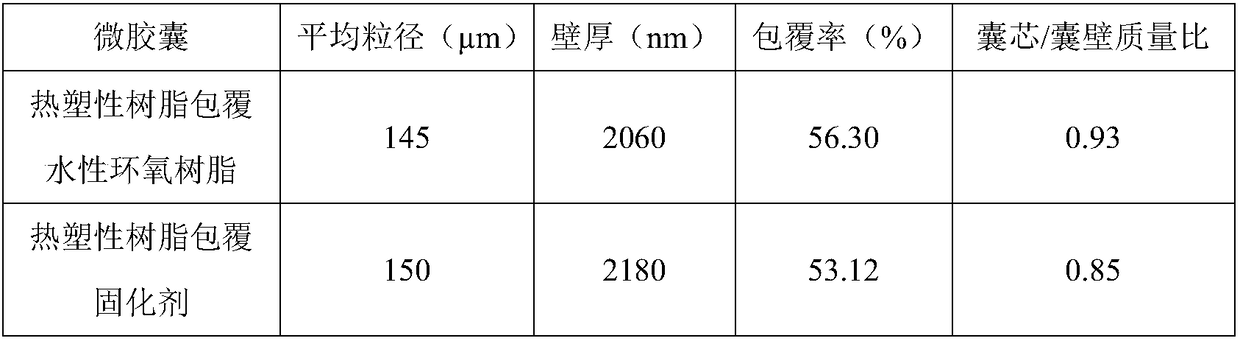

Embodiment 2

[0051] A thermoplastic resin-coated water-based epoxy resin type cement concrete crack self-repairing microcapsule, prepared as follows:

[0052] (1) The preparation of water-based epoxy resin microcapsules is roughly the same as in Example 1, except that: a. Weigh 55 parts of paraffin (melting point is 60-62° C.), 10 parts of C9 petroleum resin, and 35 parts of water-based epoxy resin (solid content 55%); b. 55 parts of paraffin and 40 parts of perfluorotributylamine are mixed, heated to 72 ° C, stirred at a speed of 400 to 600 rpm for 30 minutes, and the paraffin is melted and dispersed in the perfluorotributylamine solution, Obtain paraffin / perfluorotributylamine mixed solution;

[0053] (2) The preparation of solidifying agent microcapsules is roughly the same as in Example 1, except that: a. 60 parts of paraffin (melting point is 60~62° C.), 10 parts of C9 petroleum resin, and 30 parts of triethylenetetramine are weighed; b. .Mix 60 parts of paraffin and 40 parts of perf...

Embodiment 3

[0059] A thermoplastic resin-coated water-based epoxy resin type cement concrete crack self-repairing microcapsule, prepared as follows:

[0060] (1) The preparation of water-based epoxy resin microcapsules is roughly the same as in Example 1, except that: a. Weigh 42 parts of paraffin wax (fusing point is 52~54 ℃), 8 parts of C9 petroleum resin, and 50 parts of water-based epoxy resin (solid content 50%); b. 42 parts of paraffin and 30 parts of perfluorotributylamine are mixed, heated to 68 ° C, stirred at a speed of 400 to 600 rpm for 30 minutes, and the paraffin is melted and dispersed in the perfluorotributylamine solution, Obtain paraffin / perfluorotributylamine mixed solution;

[0061] (2) The preparation of solidifying agent microcapsules is roughly the same as in Example 1, except that: a. 55 parts of paraffin (fusing point is 52~54° C.), 8 parts of C9 petroleum resin, and 37 parts of triethylenetetramine are weighed; b. .Mix 55 parts of paraffin and 35 parts of perflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com