A filler-free underfill and preparation method thereof

An underfill, filler-free technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of unfavorable filling glue storage, low linear expansion coefficient, filler sedimentation, etc., and achieve good room temperature fluidity, The effect of low viscosity and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

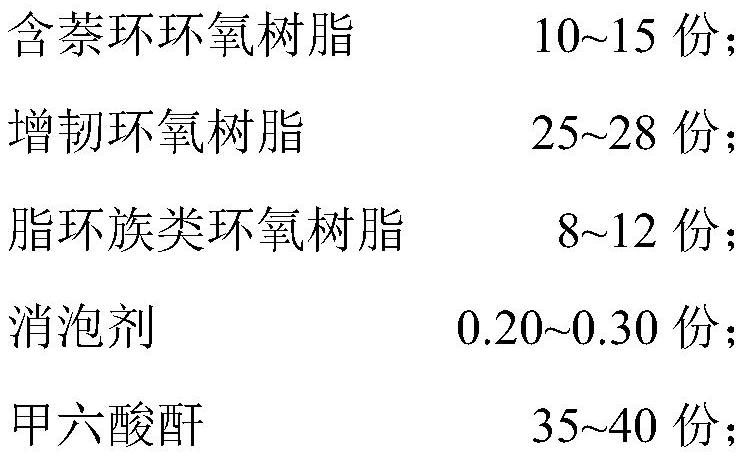

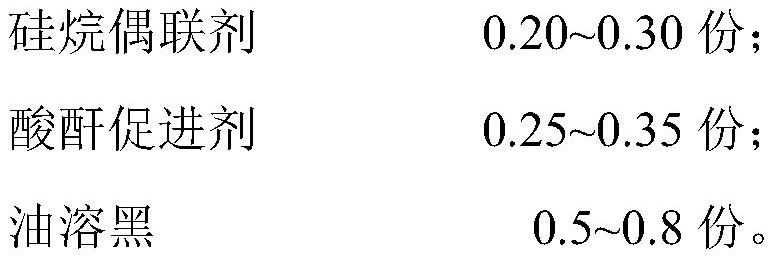

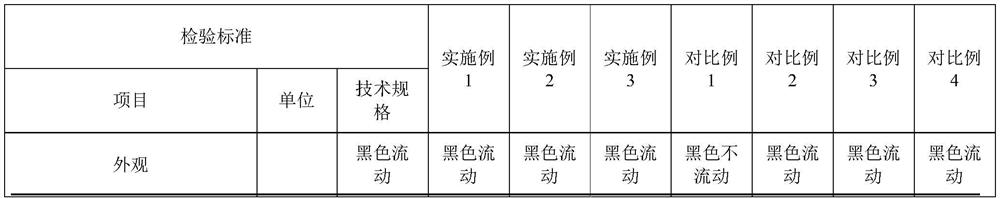

[0027] The preparation method of the above-mentioned filler-free underfill glue comprises the following steps: (a) adding the toughened epoxy resin, the epoxy resin containing naphthalene ring and the epoxy resin of cycloaliphatic group into the container, adjusting the vacuum of the container degree and temperature, stir to obtain a resin mixture; (b) mix the oil-soluble black and part of the hexaic anhydride, and stir under heating conditions until the oil-soluble black dissolves; cool to room temperature, and confirm that there are no precipitated particles to obtain a masterbatch Mixture; (c) mixing the remaining formic anhydride, acid anhydride accelerator, defoamer, silane coupling agent and the masterbatch mixture to obtain a mixed cured material; (d) adding the resin mixture and the The mixed solidified material is stirred and mixed and the vacuum degree in the reaction kettle is controlled; it only needs to go through defoaming, filtering, testing, subpackaging and deg...

Embodiment 1

[0030] This embodiment provides a filler-free underfill, which includes the following raw material components in parts by weight: 10 parts of epoxy resin containing naphthalene ring (HP-4700), 28 parts of toughened epoxy resin (epoxy soybean oil ESO ), 12 parts of cycloaliphatic epoxy resin (CYCLOMER M100), 0.30 parts of defoamer (BYK-019), 40 parts of methanelic anhydride, 0.30 parts of silane coupling agent (KH-550), 0.35 parts of anhydride accelerator (PN-23) and 0.8 parts of oil-soluble black;

[0031] The preparation method of the above-mentioned filler-free underfill comprises the following steps:

[0032] Pretreatment: Clean the grinder, reaction kettle, stirring paddle and other equipment with ethanol, drain the cleaning solution, and wipe it with a clean dry cloth; close the reaction kettle, and vacuum for 10 minutes to remove residual ethanol. Before the experiment, dry the toughened epoxy resin and cycloaliphatic epoxy resin in a blast drying oven at 115°C for 2 ho...

Embodiment 2

[0038] This embodiment provides a filler-free underfill, which is basically the same as that in Embodiment 1, except that it includes the following raw material components in parts by weight: 15 parts of epoxy resin containing naphthalene ring, toughened epoxy resin 25 parts of resin, 8 parts of cycloaliphatic epoxy resin, 0.20 part of defoamer, 35 parts of methanelic anhydride, 0.20 part of silane coupling agent, 0.25 part of anhydride accelerator and 0.5 part of oil-soluble black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com