A Mnnige-based magnetic phase change alloy with low thermal hysteresis

A technology of magnetic phase transformation and alloying, applied in the field of magnetic phase transformation alloy MnNiGe, which can solve the problems of large thermal hysteresis and reversible accompanying effects of unfavorable alloy phase transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

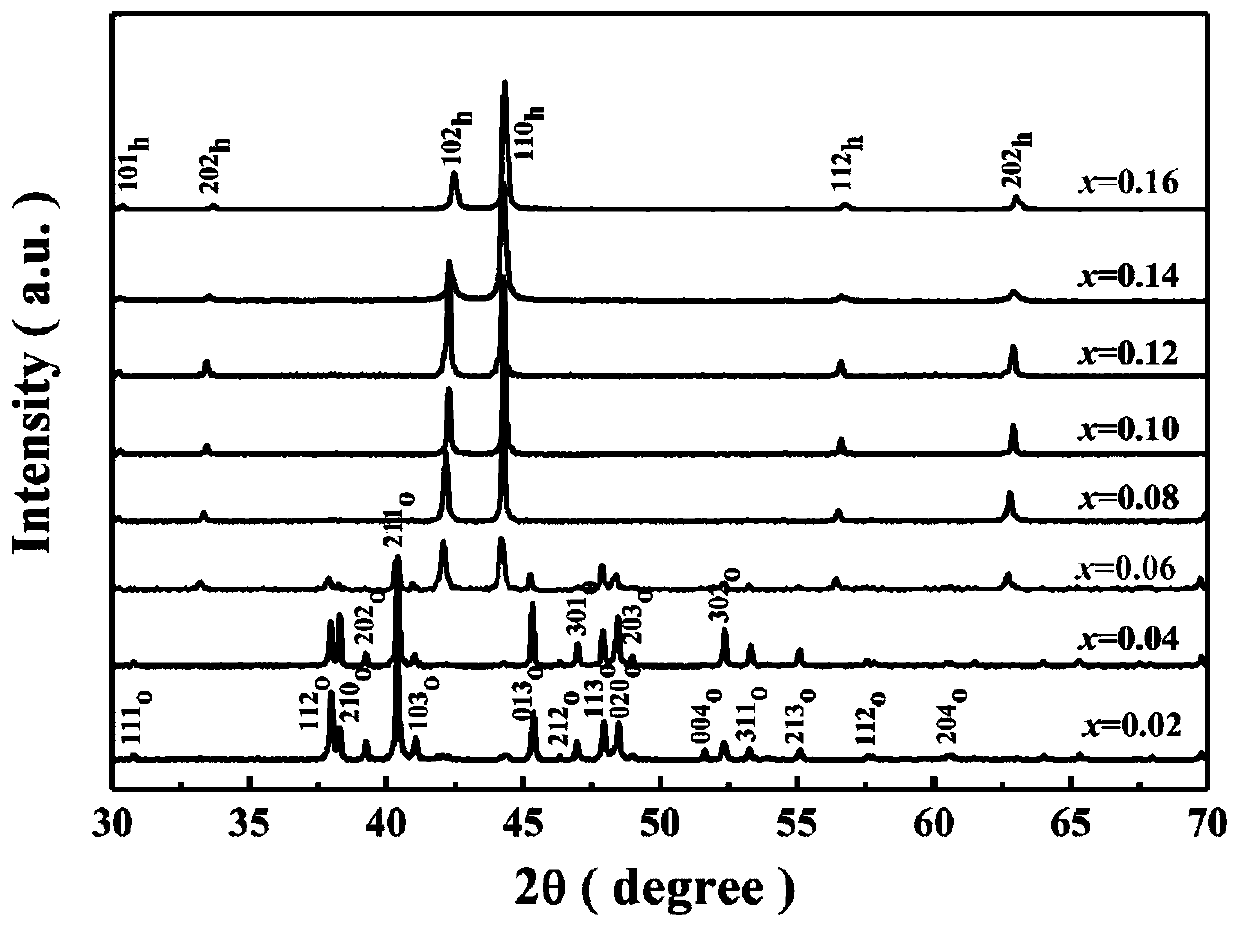

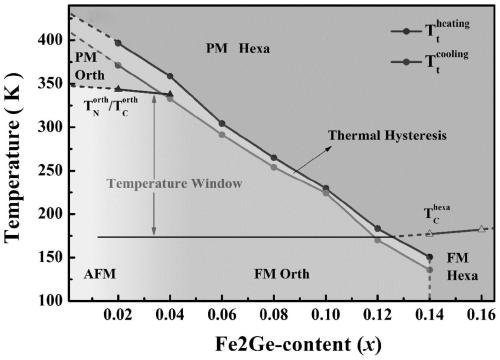

[0015] The phase structure of the alloy was characterized by X-ray Diffraction (XRD). figure 1 Yes (MnNiGe) 1-x (Fe 2 Ge) x Alloy ( 0.02≤ x ≤ 0.16 ) room temperature XRD diffraction data, with x With the increase of , the room temperature structure of the system gradually changes from high temperature hexagonal Ni 2 The In-type structure transforms into a low-temperature orthorhombic TiNiSi-type structure, which suggests that the Fe 2 The introduction of Ge lowers the structural phase transition temperature of the alloy.

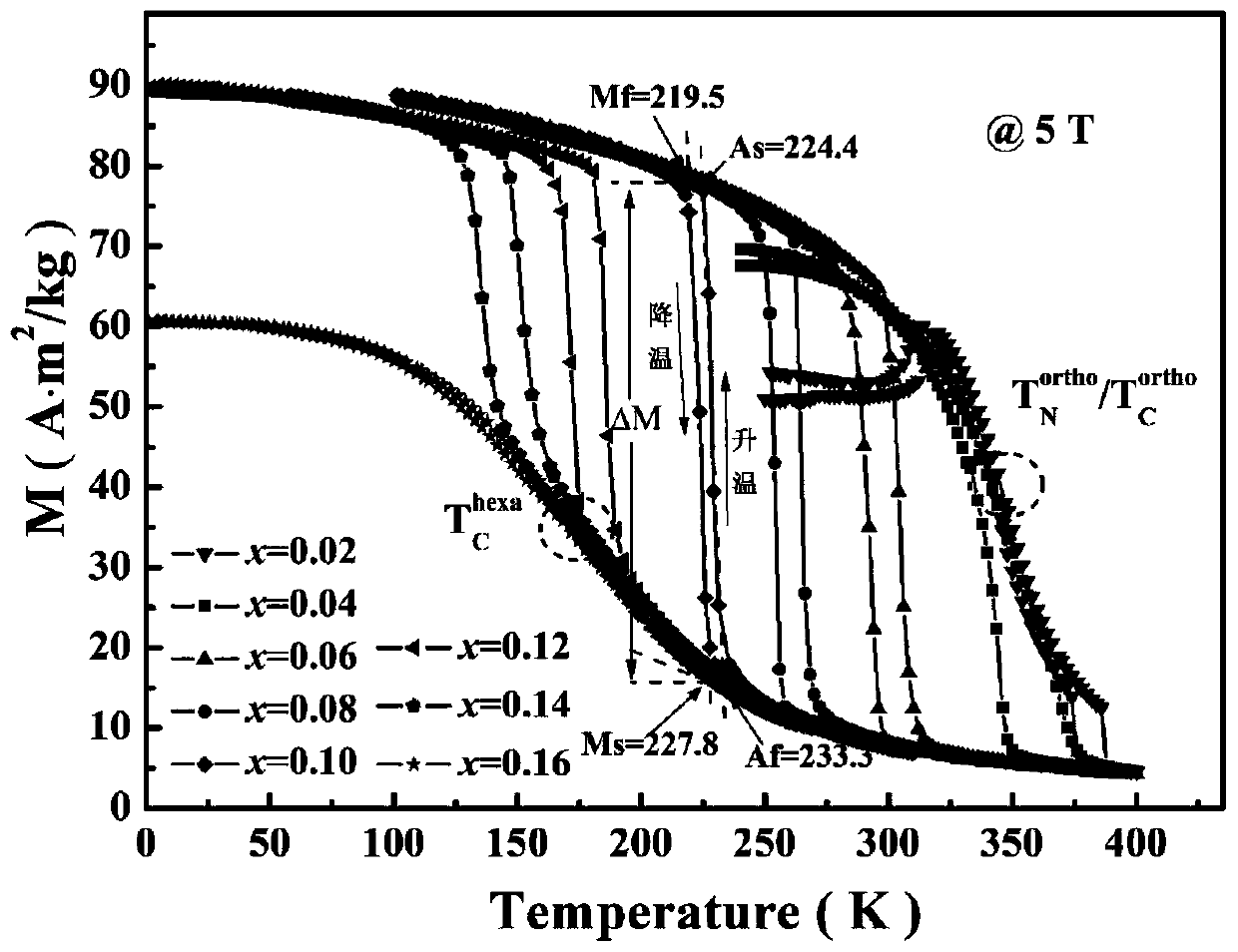

[0016] Measured by Physical Property Measurement System (PPMS) (MnNiGe) 1-x (Fe 2 Ge) x Alloy ( 0.02≤ x ≤ 0.16 ) isothermal magnetization curves and temperature-dependent magnetization. figure 2 It is under 5 T field (MnNiGe) 1-x (Fe 2 Ge) x Alloy ( 0.02≤ x ≤ 0.16 ) magnetization versus temperature. x = 0.02 A magnetization jump occurs in the sample near 380 K, and the corresponding heating and cooling curves do not overlap, which indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com