Treatment method for the bottom of the large flat-bottomed storage tank to fit the supporting surface of the foundation cap

A technology of foundation bearing platform and treatment method, which is applied in the field of large tank construction, can solve the problems of the stress of the bottom plate accessories, the difficulty of repairing, the uncertainty of the force of the bottom plate, etc., and achieves simple mechanical performance, significant economic value, and save construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following, the present invention is further described through embodiments in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

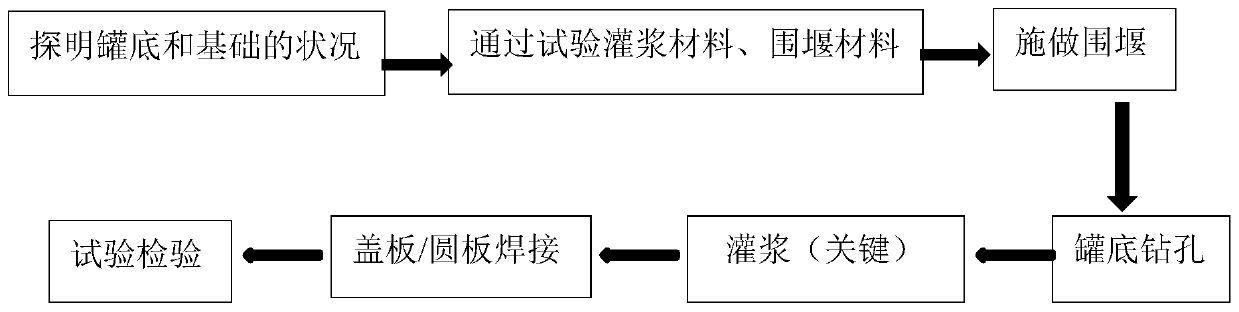

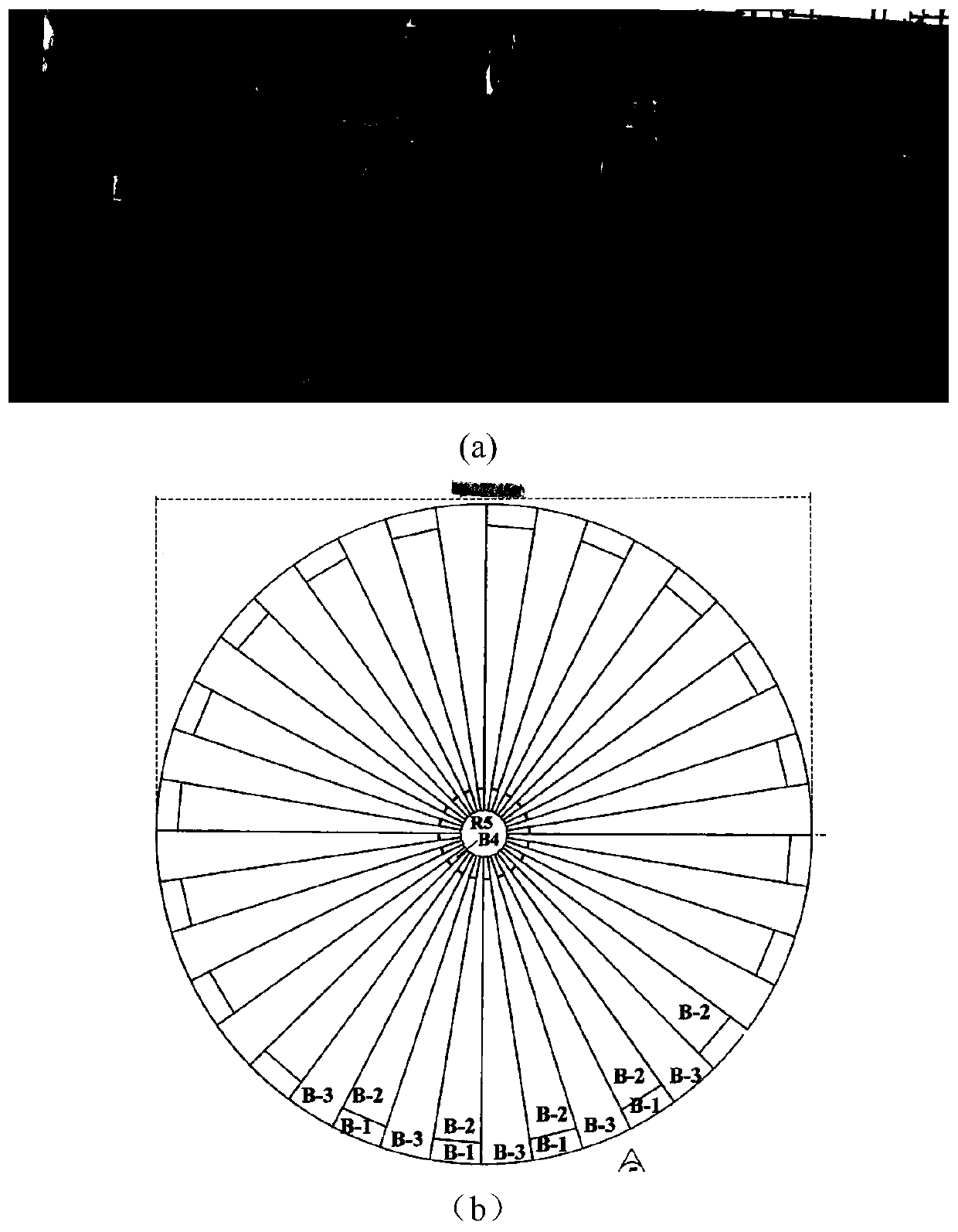

[0041] The present invention provides a method for processing the bottom of a large flat-bottomed storage tank to fit the supporting surface of a foundation platform. Secondary grouting is performed on the gap between the tank bottom plate and the platform to fill the cavity between the tank bottom and the foundation platform. The bottom of the tank and the supporting surface of the foundation platform are completely attached to avoid the stress distribution problem of the bottom of the tank. At the same time, it can avoid the vertical displacement of the bottom of the gap due to the change of the height of the liquid level inside the tank. The stress state avoids the fatigue of the bottom plate; the technical scheme of the present invention is suitable for the treatment of the gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com