Kitchen ventilator and working method thereof

A working method and technology of a range hood, which are applied in the fields of removing oil fume, heating method, and household heating, etc., can solve the problems of wind resistance, low wind pressure of the range hood, troublesome operation, etc., so as to overcome the influence of wind resistance, high decontamination efficiency, wind foot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

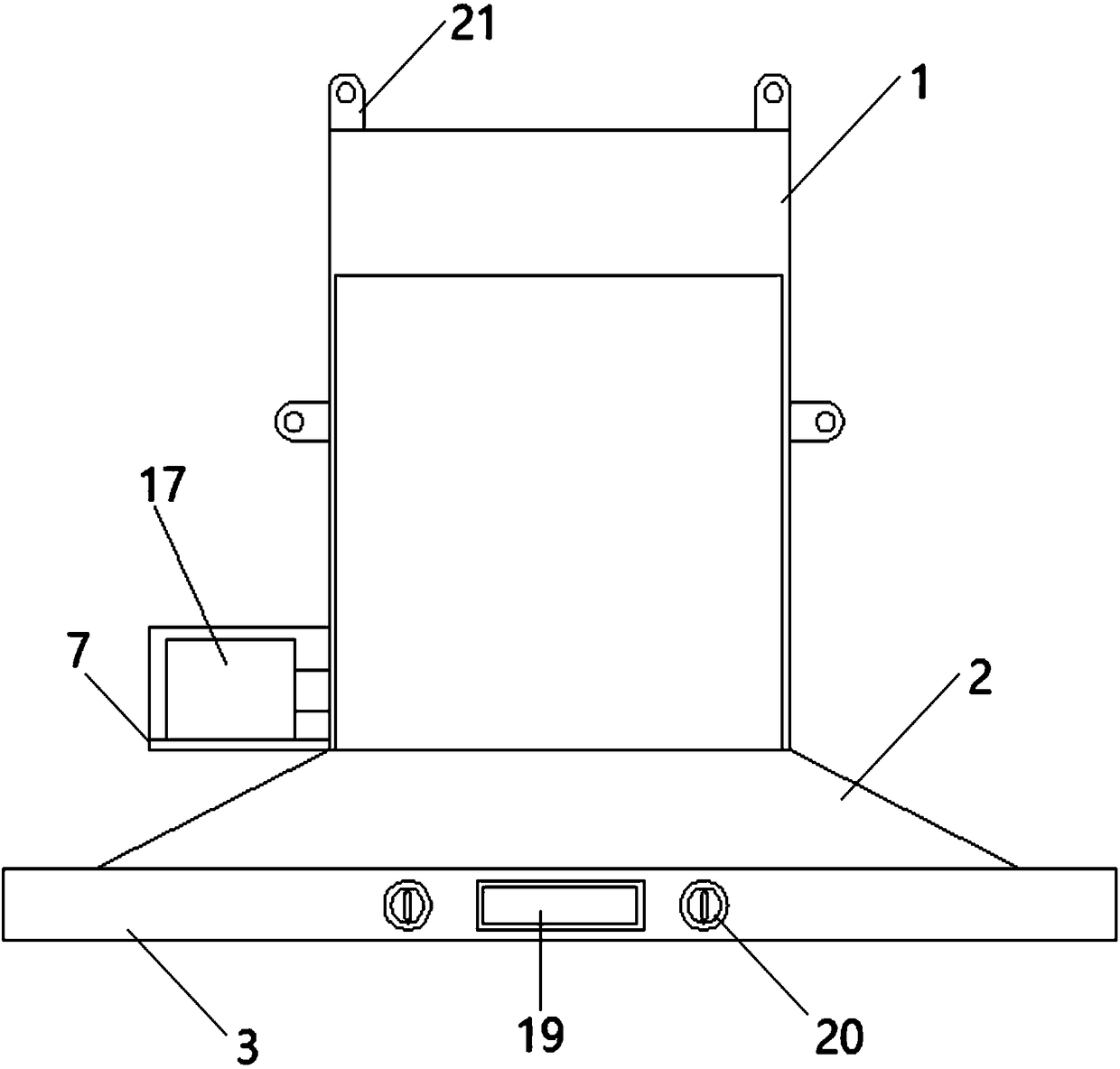

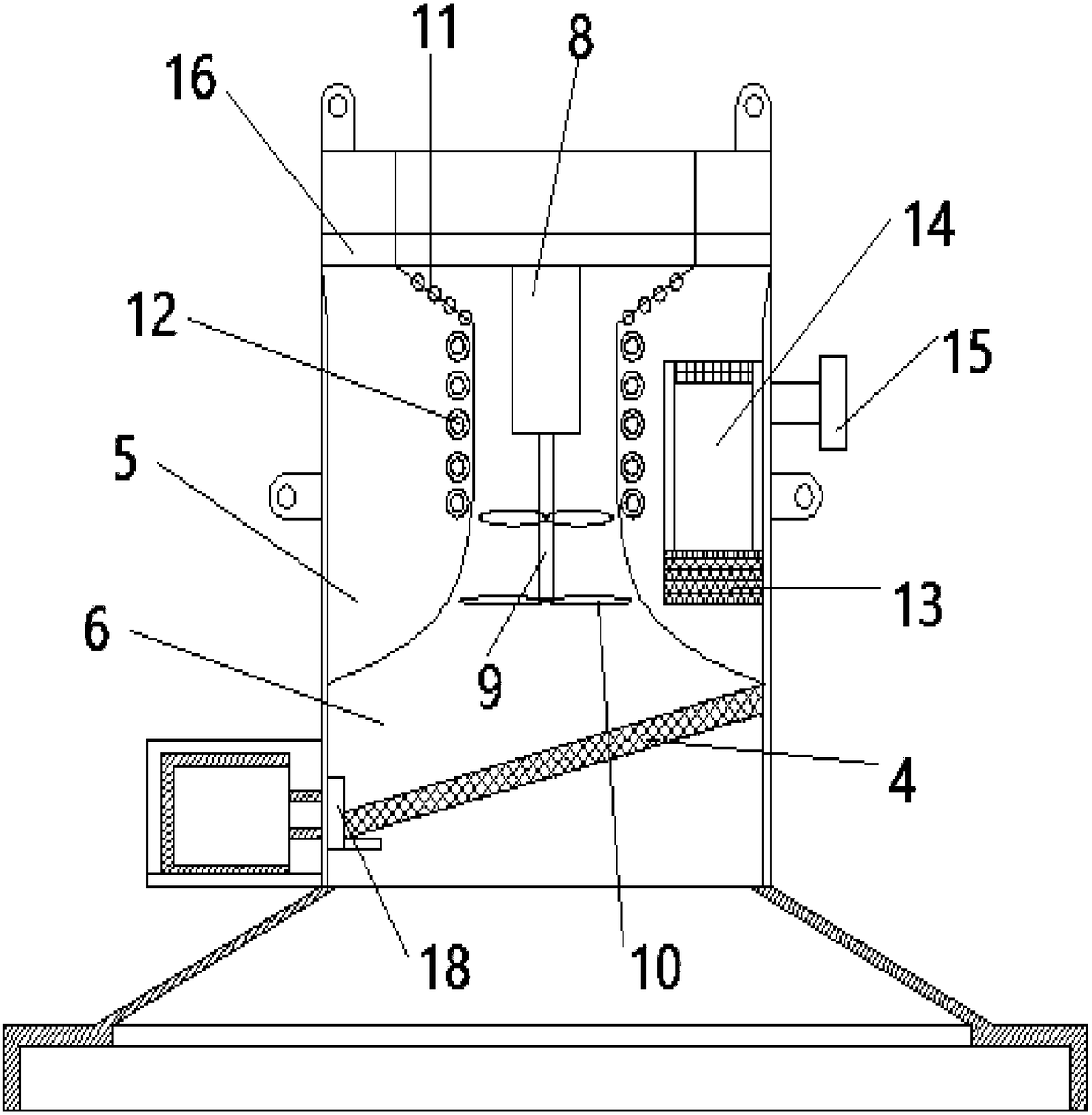

[0013] Such as Figure 1-Figure 2 As shown, a range hood includes a casing 1, a conical cover 2, and a smoke collection chamber 3, and the smoke collection chamber 3 is used to collect oil fumes. The casing 1, the conical cover 2, and the smoke collection chamber 3 are all formed from sheet metal. They are connected sequentially from top to bottom. An oil-gas separation cover 4 arranged obliquely is clamped between the lower inner walls of the casing 1. The angle between the oil-gas separation cover 4 and the horizontal plane is 10 degrees to 30 degrees. The upper inner wall of the casing 1 is provided with The trumpet-shaped cavity 5 is used to reduce wind resistance and provide installation space at the same time. The guide air duct 6 is formed between the cavity 5. The top of the cavity 5 is horizontally provided with a mounting frame 7. The mounting frame 7 The middle part of the lower surface is fixed with a drive motor 8, and the motor shaft 9 is arranged below the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com