Frost prevention machine blade production technology

A production process and anti-frost machine technology, which is applied in the field of production process of anti-frost machine blades, can solve the problems of high price and small anti-frost area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

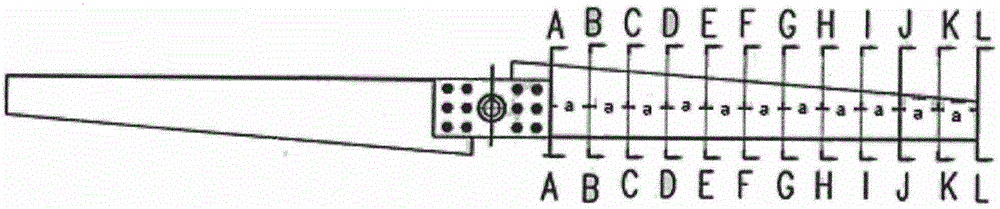

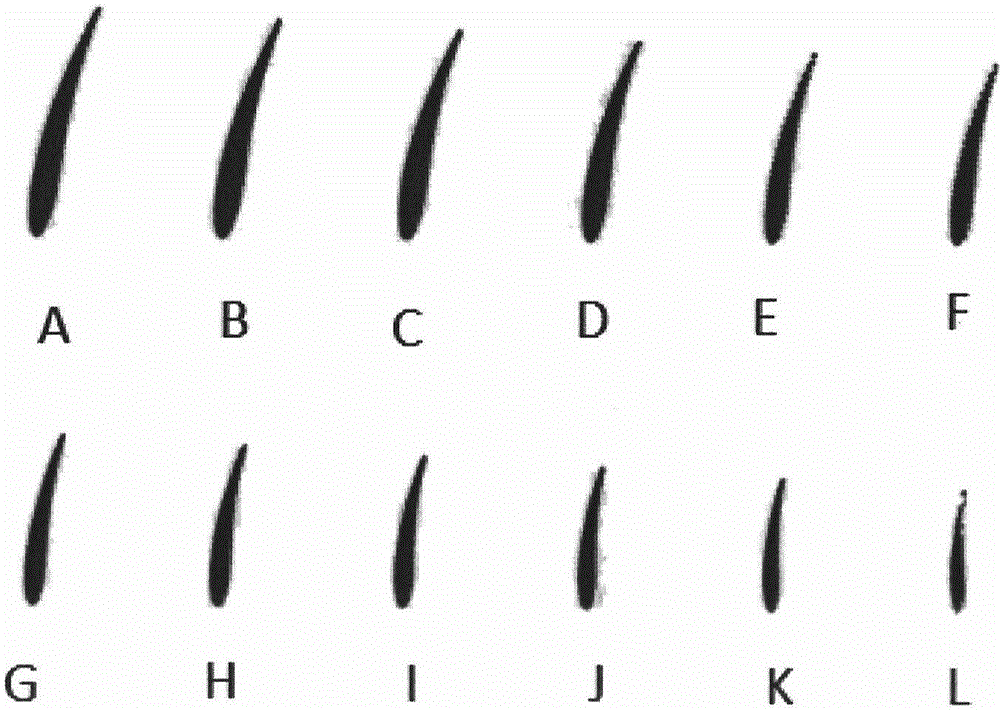

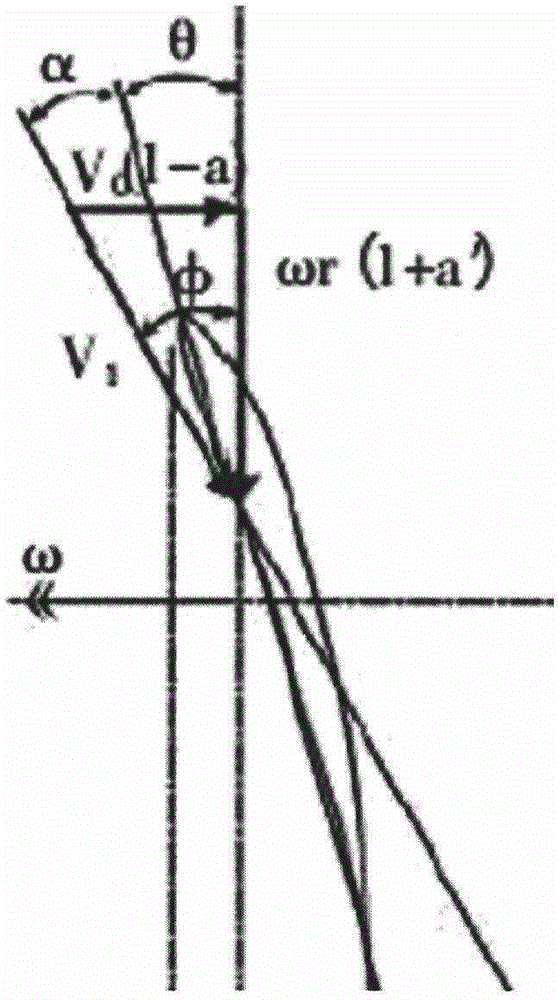

[0061] Such as figure 1 Shown is the structural representation of blade in the production technology of frost protection machine blade of the present invention; As figure 2 shown as figure 1 Middle blade every 100mm node cross-sectional view, a kind of production technology of anti-frost machine blade of the present invention, comprises the steps:

[0062] 1) Preparation of glass fiber cloth: composed of the following components by weight percentage: SiO2: 58.0-62.2%; TiO2: 0.3-1.5%; Al2O3: 12.0-14.0%; Fe2O3: 0.2-0.4%; CaO: 22.0-23.0% ; LiO2: 0.1-0.5%; MgO: 2.5-2.8%; WO3: 0-1.0%; Na2O: 0.35%; K2O: 0.15%; CeO2: 0.2-0.5%;

[0063] 2) Preparation of the mold: prepare the blade airfoil model, and process the blade mold with a CNC machine tool;

[0064] 3) Preparation of resin mixture: add activated carbon fiber wave absorbing agent into ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com