Sample collection device, system, method and storage medium

A technology for sample collection and sample storage, applied in sampling devices and other directions, can solve the problems of long sampling time, influence and change, and achieve the effect of short sampling time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

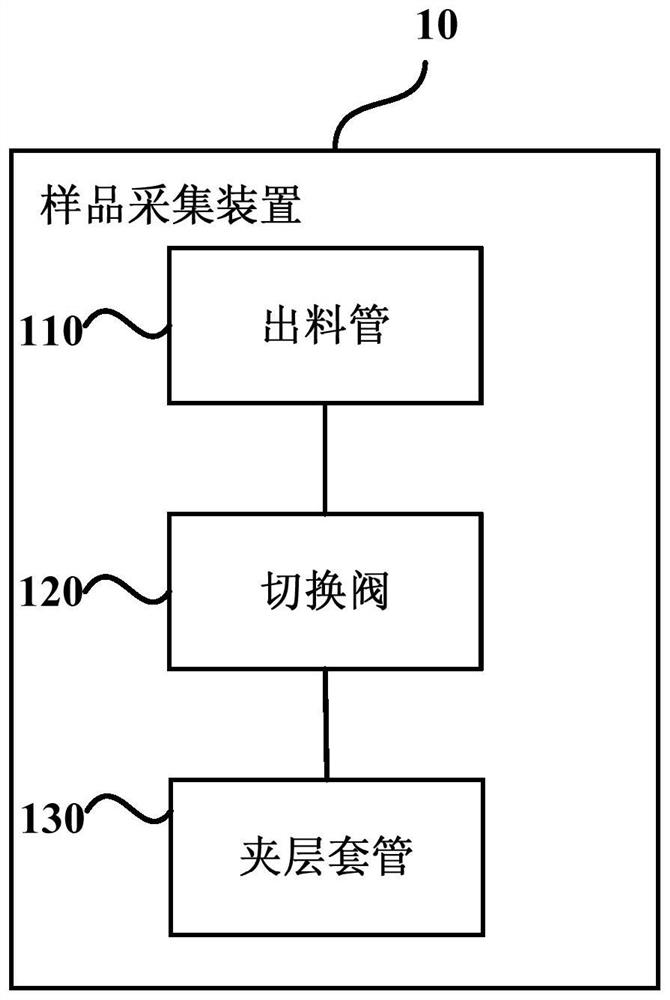

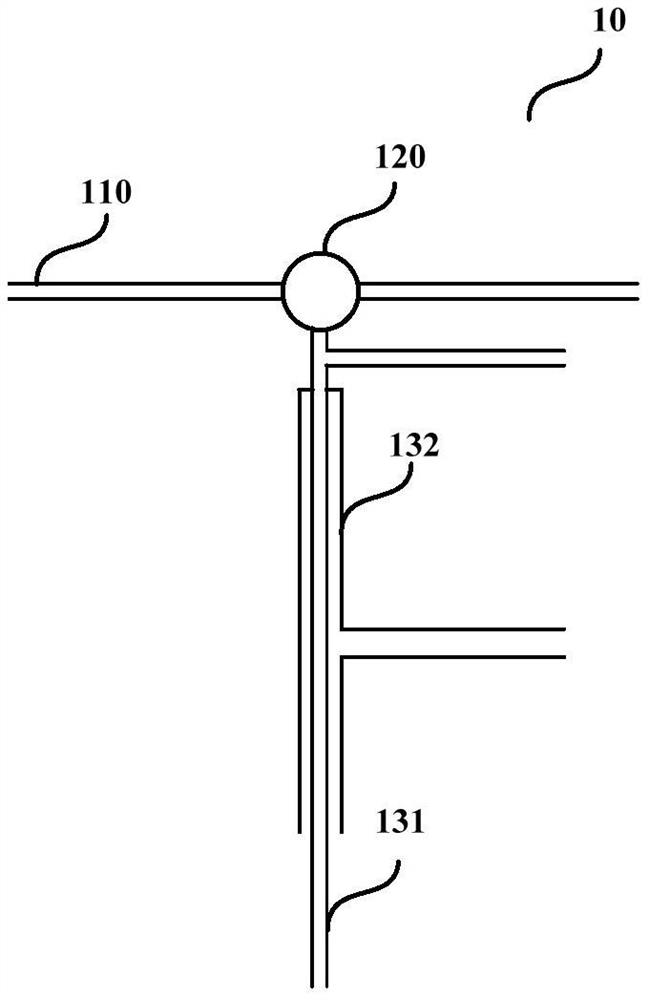

[0034] Figure 1A It is a schematic structural diagram of a sample collection device provided in Embodiment 1 of the present invention, which is applied to particle sample collection. like Figure 1A As shown, the specific sample collection device 10 includes: a discharge pipe 110 , a switching valve 120 and a sandwich sleeve 130 .

[0035] The first port of the discharge pipe 110 is connected to the sample reaction device, and the second port of the discharge pipe 110 is connected to the first port of the switching valve 120 for transferring samples;

[0036] The second port of the switching valve 120 is connected with the inner layer pipeline of the sandwich sleeve 130 for transferring the sample to the sample storage device; the third port of the switching valve 120 is connected with the purging device for cleaning after the sampling is finished. Purge sample reaction device and sample storage device;

[0037] The outer pipeline of the sandwich casing 130 is connected with...

Embodiment 2

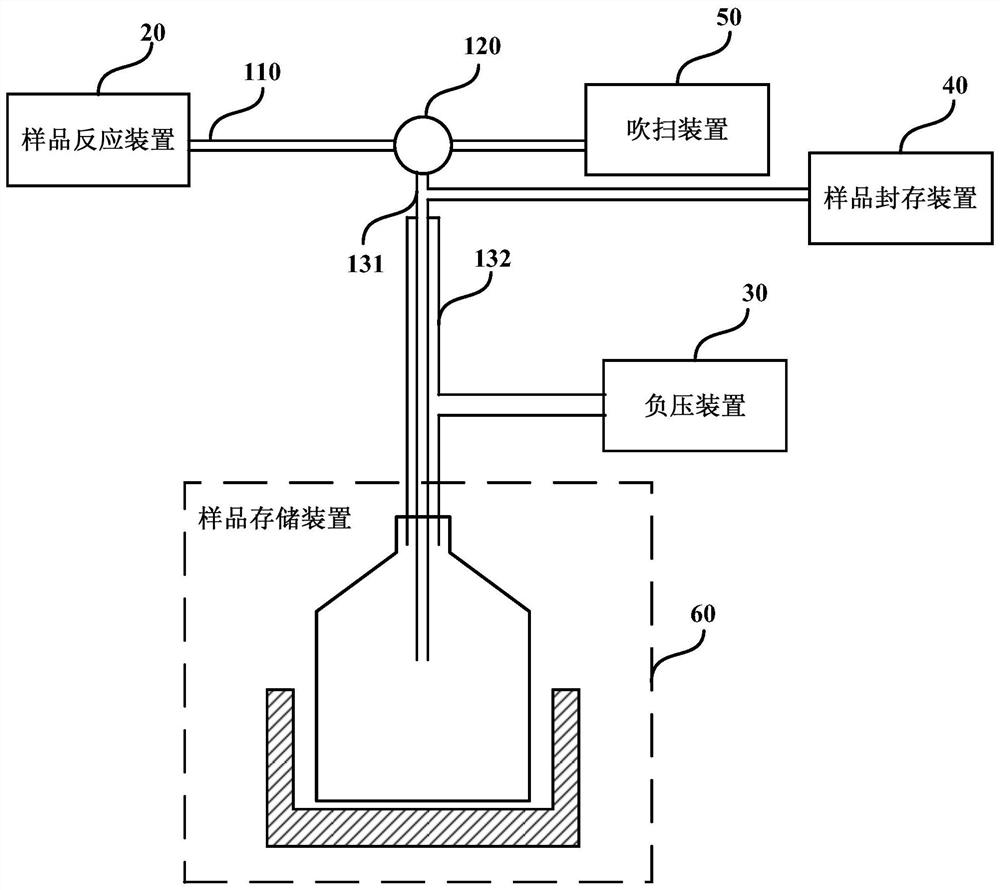

[0048] Figure 2A It is a schematic diagram of a sample collection system provided in Embodiment 2 of the present invention. like Figure 2A As shown, the sample collection system includes: a sample collection device 10, a sample reaction device 20, a negative pressure device 30, a sample sealing device 40, a purging device 50, and a sample storage device 60;

[0049] The sample collection device 10 communicates with the sample reaction device 20 , the negative pressure device 30 , the sample sealing device 40 , the purging device 50 and the sample storage device 60 respectively.

[0050] Figure 2B It is a detailed structural schematic diagram of a sample collection system, providing a detailed structural schematic diagram of a sample reaction device, a negative pressure device, a sample storage device, a purging device and a sample storage device for continuous online collection of solid particle samples. like Figure 2B Shown:

[0051] The sample reaction device includ...

Embodiment 3

[0069] Fig. 3 is a schematic diagram of a sample collection system provided by Embodiment 3 of the present invention, in Figure 2B On the basis of the acquisition system diagram provided, it also includes: gas acquisition on-line detection device, which is used for continuous on-line solid sampling and characterization during the reaction process, and real-time analysis of gas phase components to achieve the purpose of reaction evaluation.

[0070] like Figure 3A As shown, it includes a second filter 710, a fourth valve 720, a shut-off valve 730 and a gas component detector 740 for online detection of gas samples in the reaction process; wherein, the gas component detector 740 and the first stop valve 730 The ports are connected, the second port of the stop valve 730 is connected with the first port of the fourth valve 720, the second port of the fourth valve 720 is connected with the first port of the second filter 710, and the second port of the second filter 710 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com