Insulator defect detection method, system and terminal equipment

A defect detection and insulator technology, applied in the field of defect detection, can solve problems such as heavy workload, poor safety, and low detection accuracy, and achieve the effects of realizing hidden safety hazards, improving detection accuracy, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

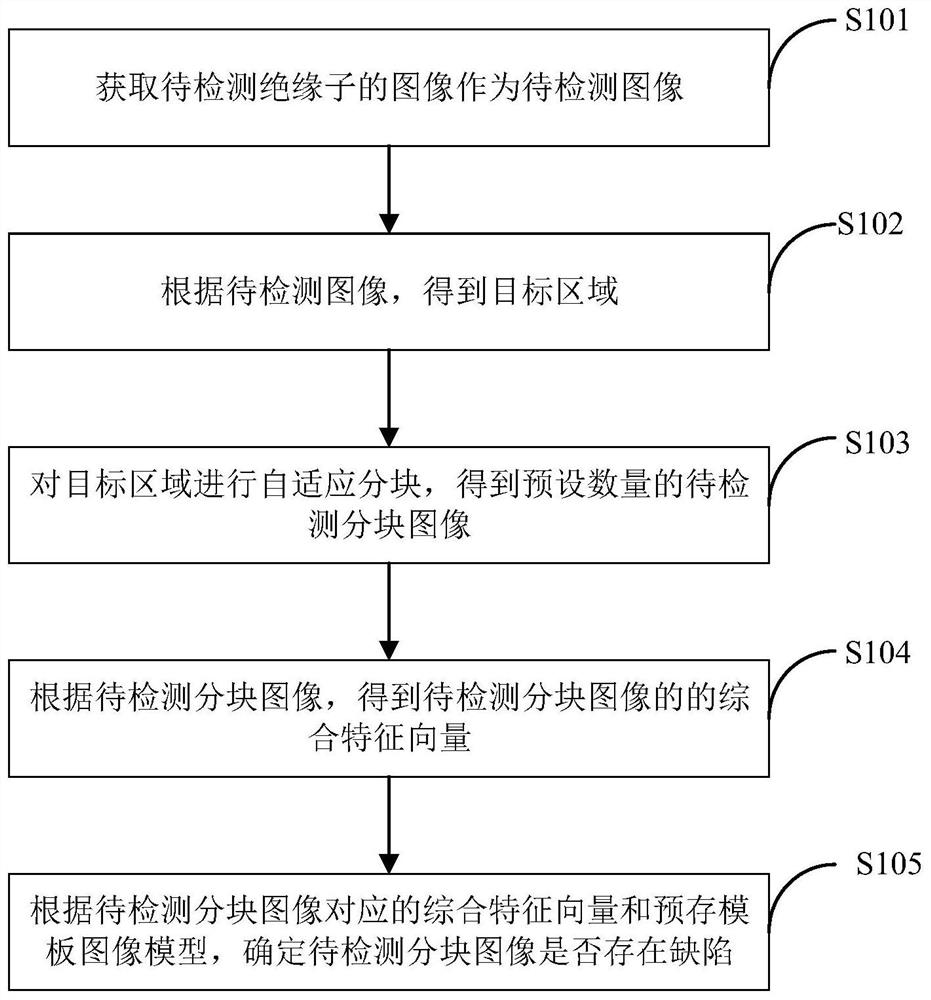

[0033] figure 1 It shows the implementation flow of an insulator defect detection method provided by an embodiment of the present invention, and the process is described in detail as follows:

[0034] In step S101, an image of an insulator to be detected is acquired as an image to be detected.

[0035] In this embodiment, the method of acquiring the image of the insulator to be tested can be taken by a drone, or can be acquired by a fixed camera installed near the insulator to be tested.

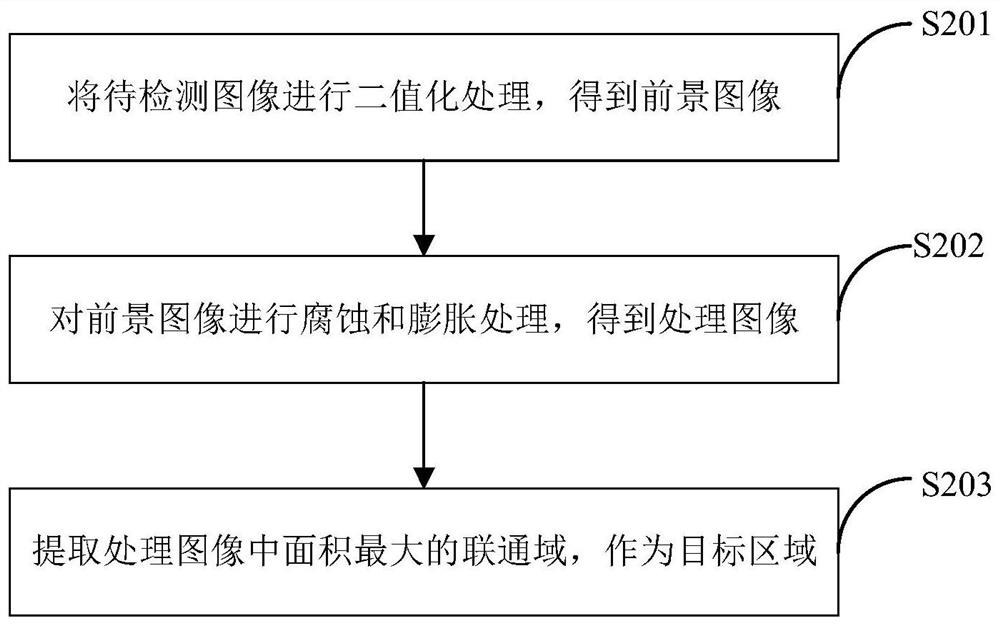

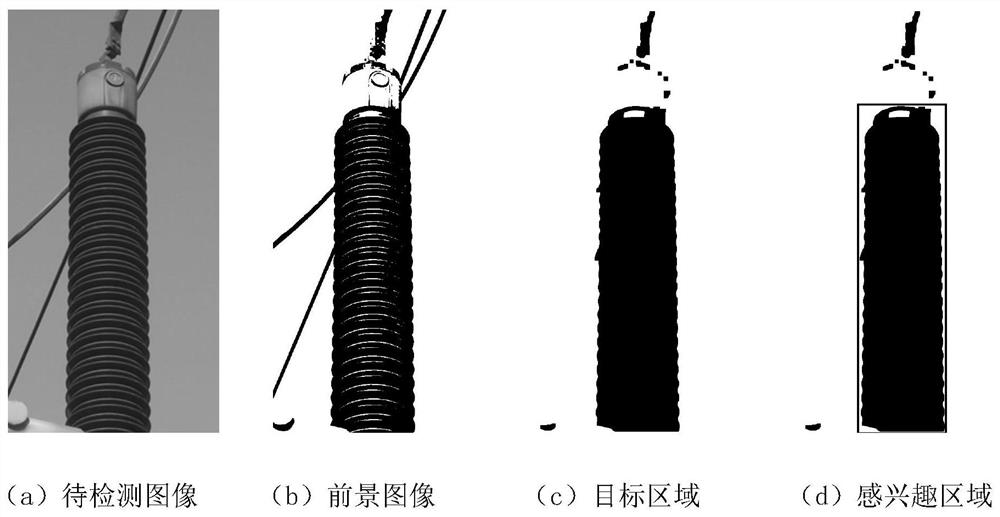

[0036] In step S102, the target area is obtained according to the image to be detected.

[0037] In step S103, the target area is adaptively segmented to obtain a preset number of segmented images to be detected.

[0038] In step S104, according to the block image to be detected, a comprehensive feature vector of the block image to be detected is obtained.

[0039] In step S105, it is determined whether there is a defect in the block image to be detected according to the comprehensive fea...

Embodiment 2

[0108] Such as Figure 5 As shown, an embodiment of the present invention provides an insulator defect detection system 100 for performing figure 1 The method step in the corresponding embodiment, it comprises:

[0109] The image acquisition module 110 to be detected is used to obtain the image of the insulator to be detected as the image to be detected;

[0110] The target area acquisition module 120 is used to obtain the target area according to the image to be detected;

[0111] The segmented image to be detected acquisition module 130 is used for adaptively segmenting the target area to obtain a preset number of segmented images to be detected;

[0112] The integrated feature vector generation module 140 is used to obtain the integrated feature vector of the block image to be detected according to the block image to be detected;

[0113] The defect judging module 150 is configured to determine whether the block image to be detected has defects according to the comprehen...

Embodiment 3

[0147] Such as Figure 8 As shown, the embodiment of the present invention also provides a terminal device 8, including a memory 81, a processor 80, and a computer program 82 stored in the memory 81 and operable on the processor 80, and the processor 80 executes the The computer program 82 realizes the steps in each embodiment as described in Embodiment 1, for example figure 1 Step S101 to step S105 are shown. Alternatively, when the processor 80 executes the computer program 82, it realizes the functions of each module in each device embodiment as described in Embodiment 2, for example Figure 4The functions of modules 110 to 150 are shown.

[0148] The terminal device 8 may be computing devices such as desktop computers, notebooks, palmtop computers, and cloud servers. The terminal device 8 may include, but not limited to, a processor 80 and a memory 81 . For example, the terminal device 8 may also include an input and output device, a network access device, a bus, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com