Built-in containment vessel filtering discharging system

An emission system and containment technology, which is used in emergency protection devices, nuclear power generation, climate sustainability, etc., can solve the problems of inability to remove radioactive substances and tight layout space, achieve high aerosol and iodine removal efficiency, and small equipment. The effect of sizing and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

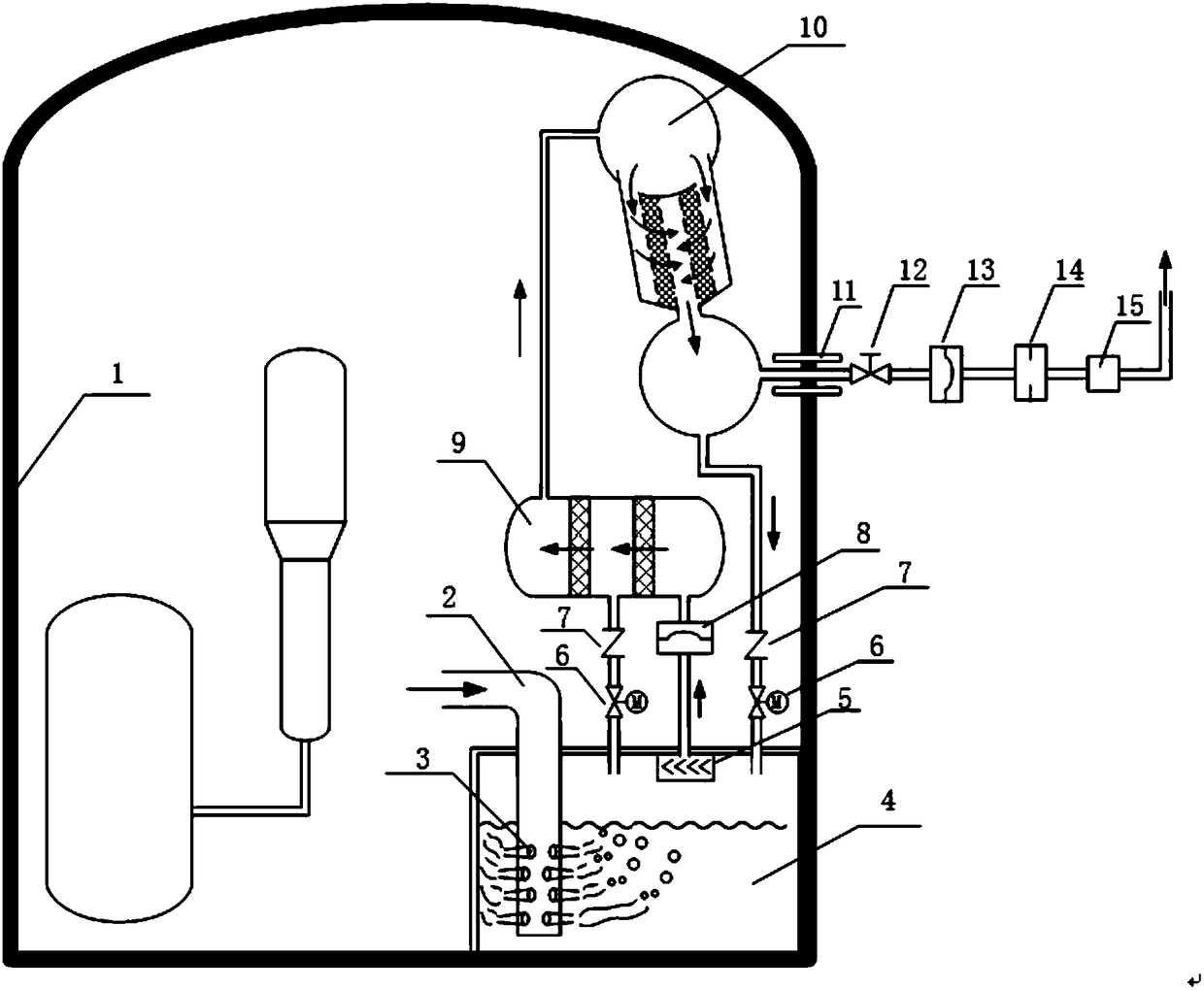

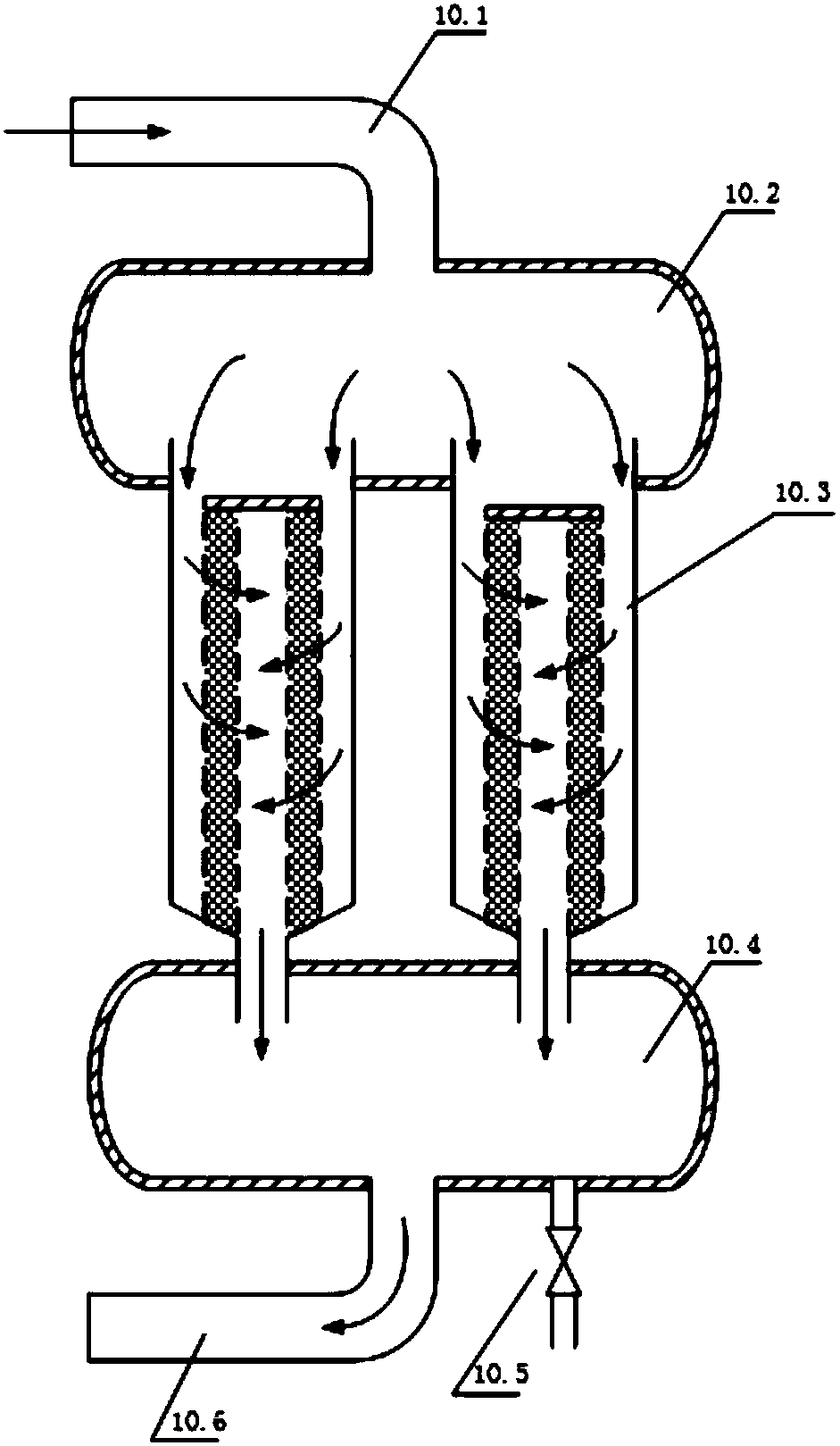

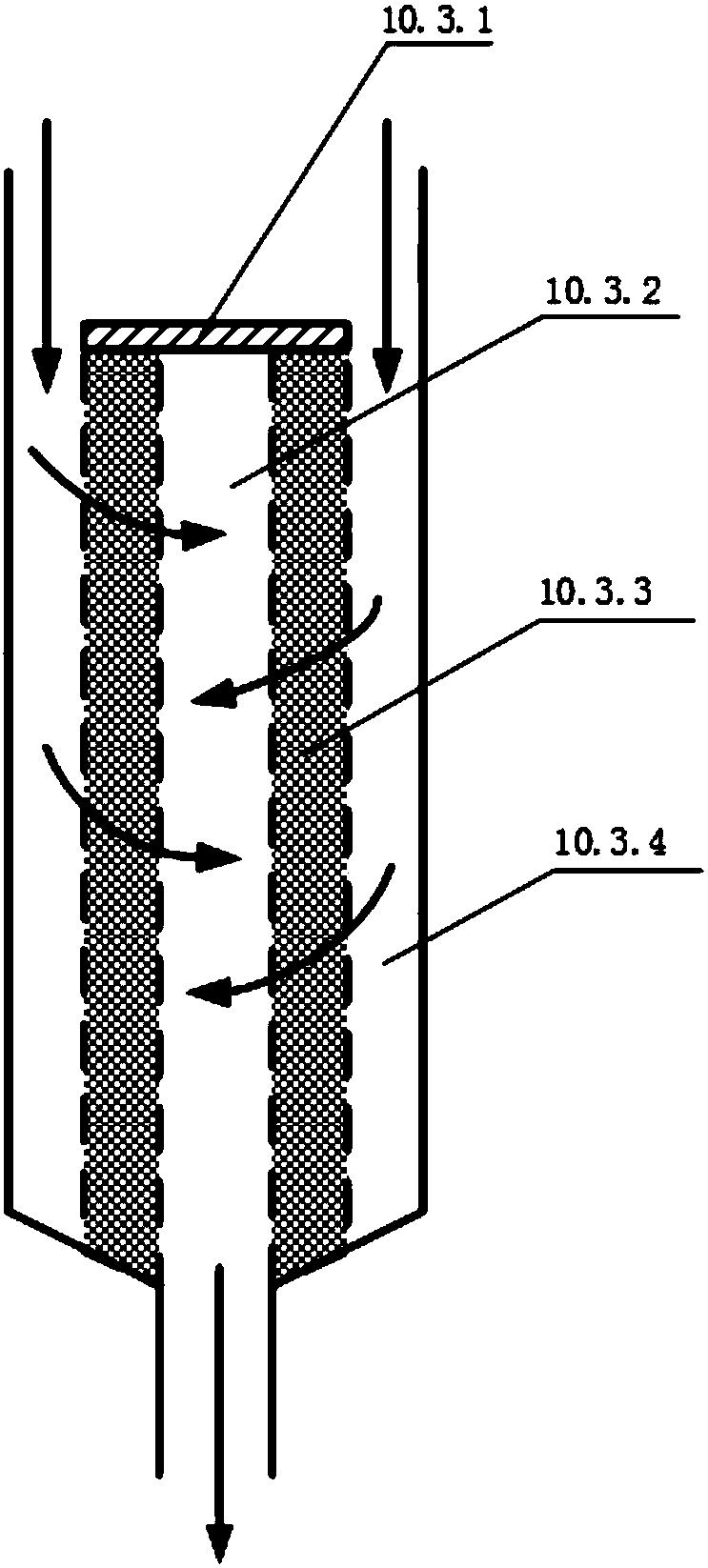

[0016] Such as figure 1 As shown, a built-in containment filtration and discharge system is composed of a built-in pool 4, a jet pipe 2, a steam-water separator 5, a metal fiber filter 9, a silver zeolite filter 10, and corresponding pipeline valves. The main equipment of the system is arranged near the side wall inside the containment vessel 1, which effectively utilizes the inner space of the containment vessel 1 and reduces the complicated arrangement of external systems. The built-in water pool 4 can be formed by adding partitions to the existing water pool in the containment vessel 1, so that the original internal space can be effectively used. Simultaneously, the volume of the built-in pool 4 is very small compared with the original pool, so the function of the original pool will not be affected. Add a certain amount of water or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com