A kind of aluminum alloy battery pack shell and its manufacturing method

A manufacturing method and technology of battery packs, which are applied to battery pack parts, circuits, electrical components, etc., can solve problems such as slag inclusions, cracks, shrinkage cavities, high structural reliability requirements, and easy stress deformation, etc., to achieve Light weight, good airtightness, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

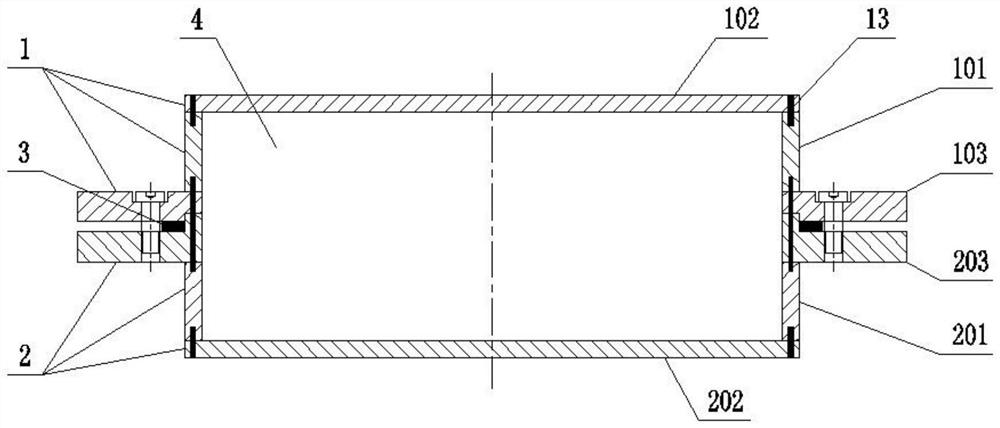

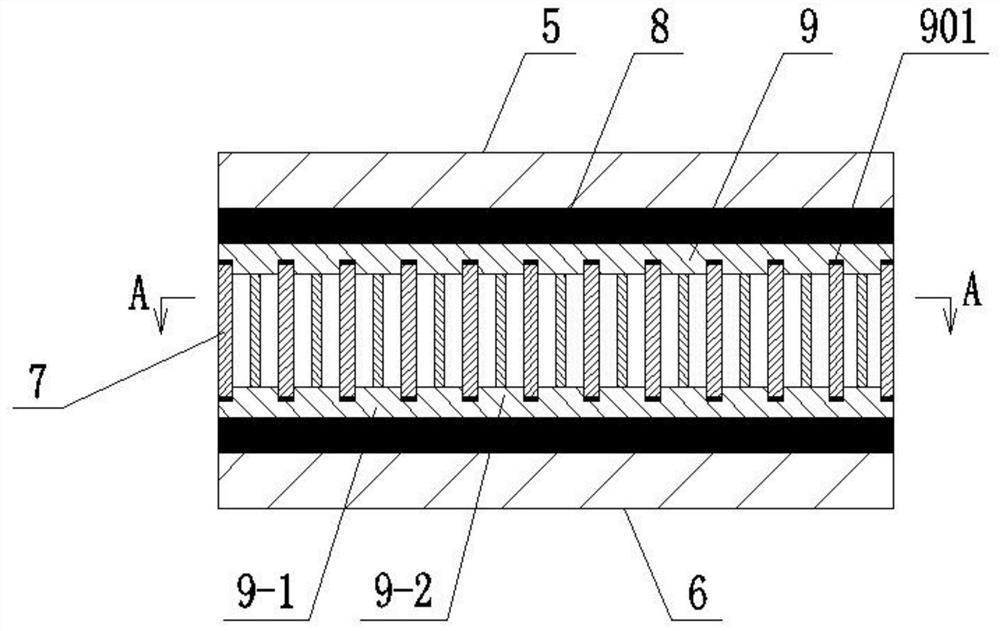

[0028] Below in conjunction with accompanying drawing, the present invention is further described;

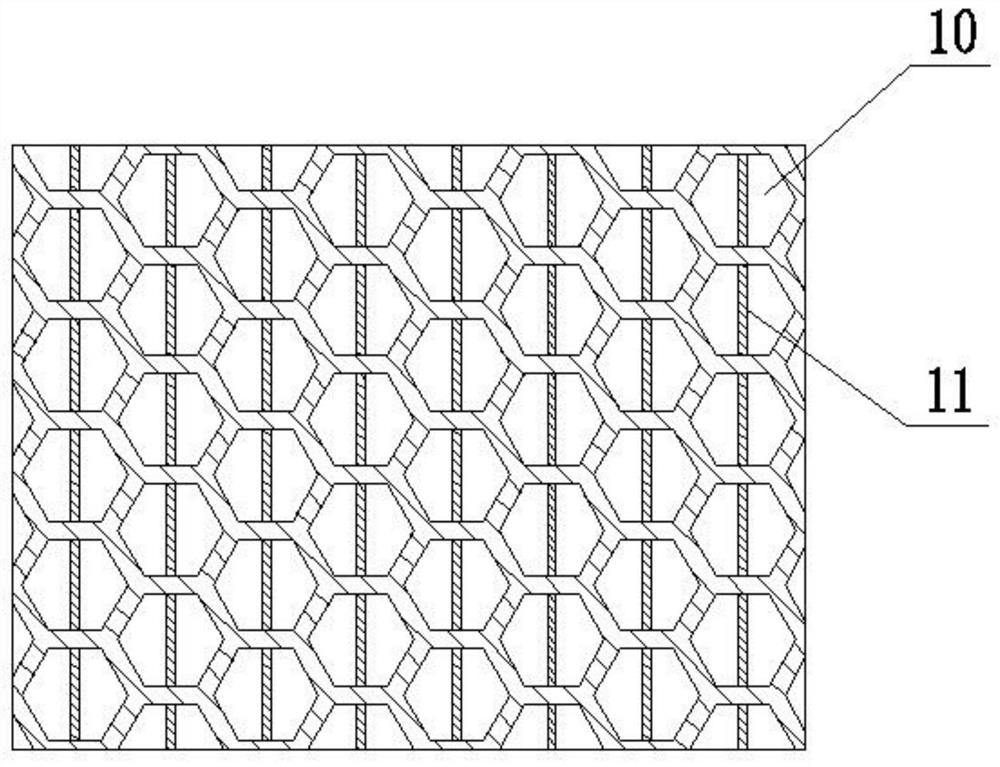

[0029] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 middle:

[0030] An aluminum alloy battery pack casing, comprising an upper cover 1, and a lower case 2 connected to the upper cover 1 by bolts; a sealing strip 3 is arranged between the upper cover 1 and the lower case 2 , and forms a space 4 for installing battery modules; the upper cover 1 and the lower case 2 are combined by aluminum alloy plates; the aluminum alloy plates include an upper layer 5, a lower layer 6, a middle The honeycomb core layer 7, and the first high temperature resistant inorganic adhesive layer 8 connected between the upper layer 5 and the middle honeycomb core layer 7, and between the lower layer 6 and the middle honeycomb core layer 7; The reinforcement layer 9 between the layer 7 and the first high-temperature-resistant inorganic adhesive layer 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com