A device for electrically dismantling motor stator windings

A motor stator and electric technology, applied in the field of disassembly tools, can solve the problems of inconvenient operation, inability to improve work efficiency, delay in disassembly work time, etc., and achieve the effect of convenient disassembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

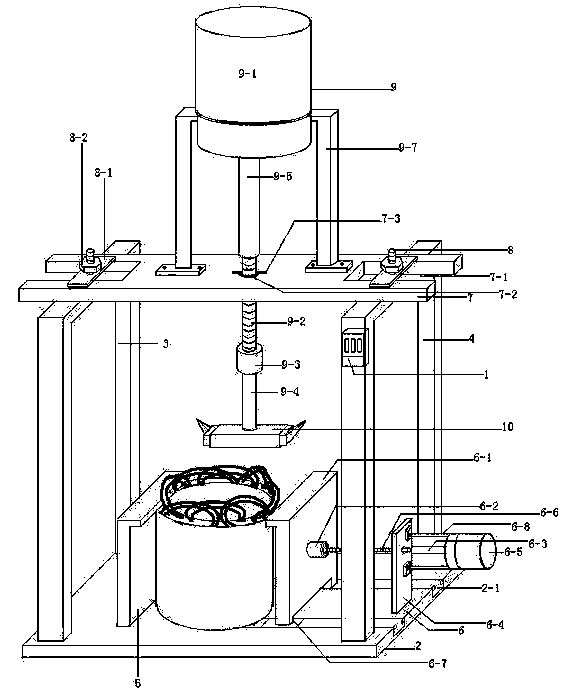

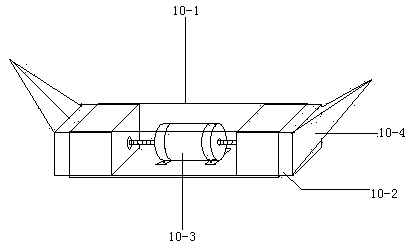

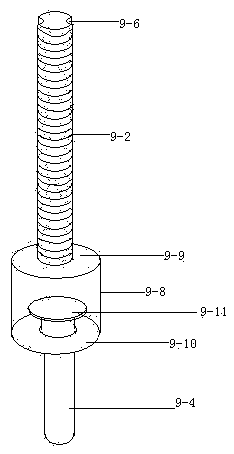

[0019] figure 1 , 2 , 3, a device for electrically dismantling the stator windings of a motor, including a switching power supply module 1 of AC 220V to DC 24V, also has a lower support plate 2, a left vertical plate 3, a right vertical plate 4, a fixed splint 5, an electric Plywood mechanism 6, horizontal support plate 7, upper locking screw 8, electric pull rod mechanism 9, electric pulling head mechanism 10, power switch 11 and component box 12, left vertical plate 3 and right vertical plate 4 are "П" type, The left vertical plate 3 and the lower part of the right vertical plate 4 are respectively welded to the upper parts of the left and right ends of the lower support plate 2, and the right part of the lower support plate 2 has a chute 2-1 horizontally from the front to the rear. The fixed splint 5 is " ┌” type, the lower part of the fixed splint 5 is welded on the left upper part of the lower support plate 2, the fixed splint 5 is located on the right side of the left v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com