Hole sowing and fertilization driving device

A driving device and hole-type technology, which is applied in the directions of fertilization device, hole-seeding planter, and sowing, can solve the problems of operation without considering the influence of the forward speed of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure and working process of the present invention will be described below in conjunction with the accompanying drawings and examples.

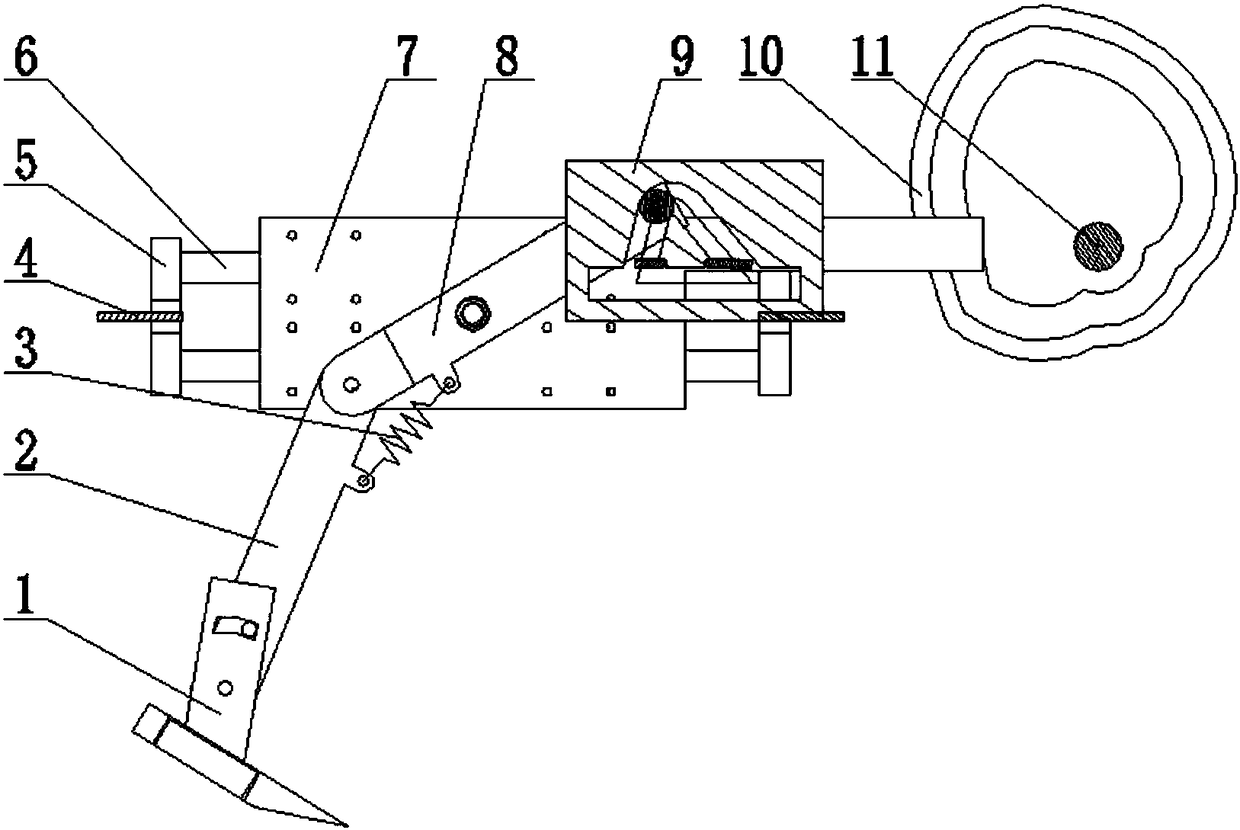

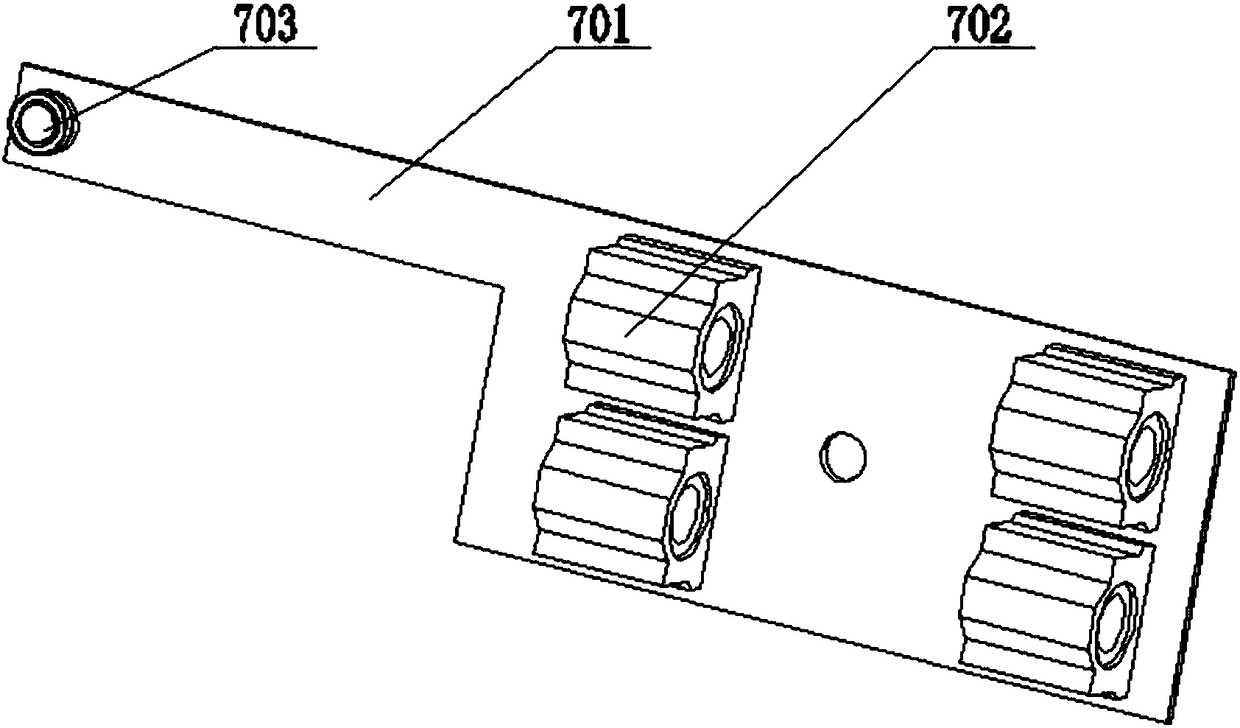

[0022] A hole-type sowing and fertilizing driving device, comprising: a seeding and fertilizing shovel 1, a secondary shovel arm 2, a tension spring 3, a connecting plate 4, a slide rail fixing seat 5, a slide rail 6, a slider assembly 7, and a primary shovel arm 8. Drive groove 9, cam 10, camshaft 11.

[0023] The connecting plate 4 is a device fixing part, and is designed with bolt holes for connecting the driving device with the machine frame.

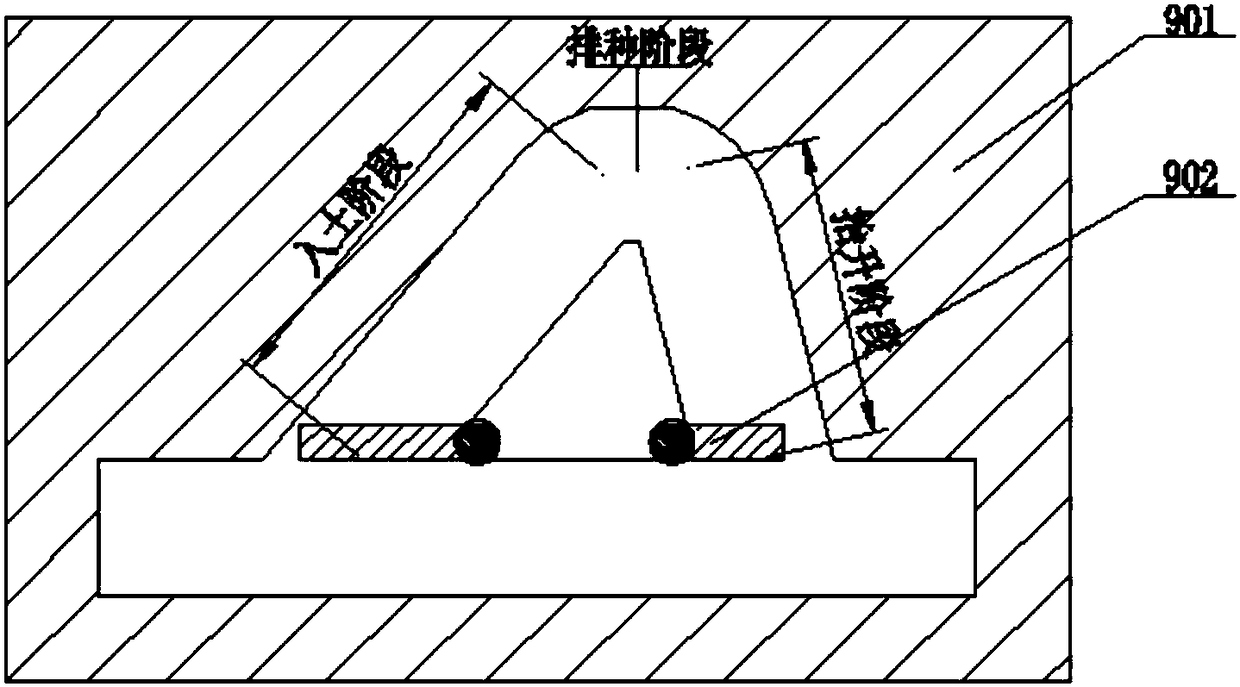

[0024] The cam 10 is installed on the camshaft 11, and the cam 10 makes a circular motion driven by the camshaft; the end of the slider assembly 7 is equipped with a bearing, and the bearing rolls in the cam groove, and then drives the slider assembly 7 along the slide rail. 6. Do reciprocating linear motion; the cam contour line is divided into 6 sections, respectively pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com