Cabbage harvesting and conveying table

A conveying table and cabbage technology, applied in the direction of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reduced harvest quality and effect, high labor intensity, and poor harvest introduction effect, etc., and achieve low manufacturing cost and generalization High degree, use reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

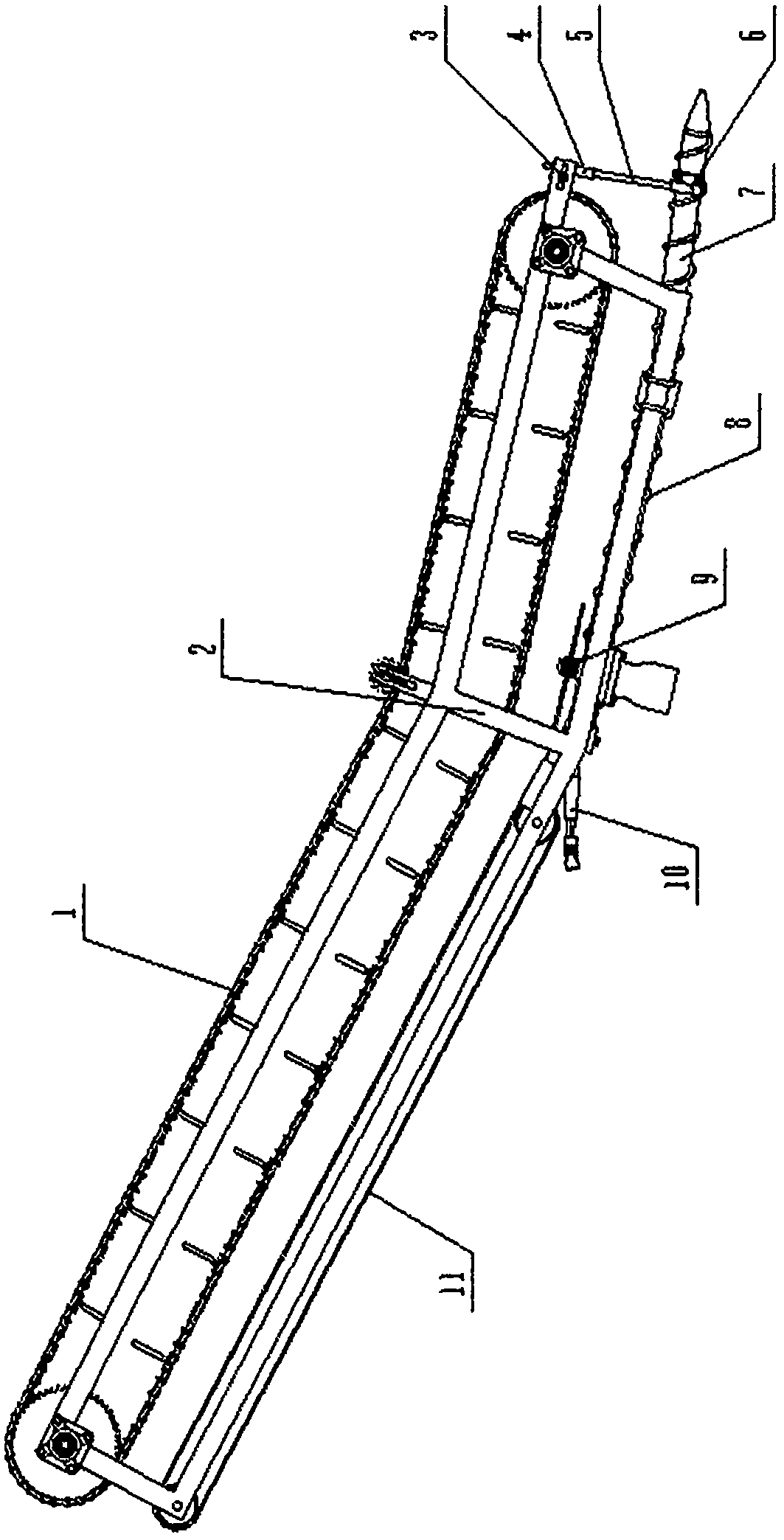

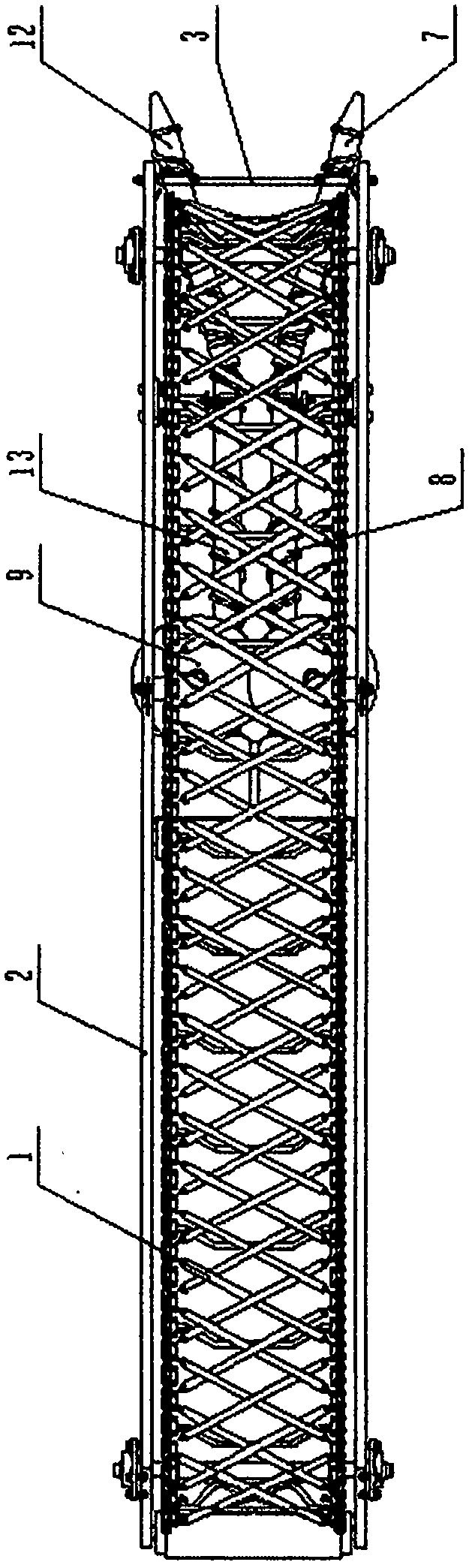

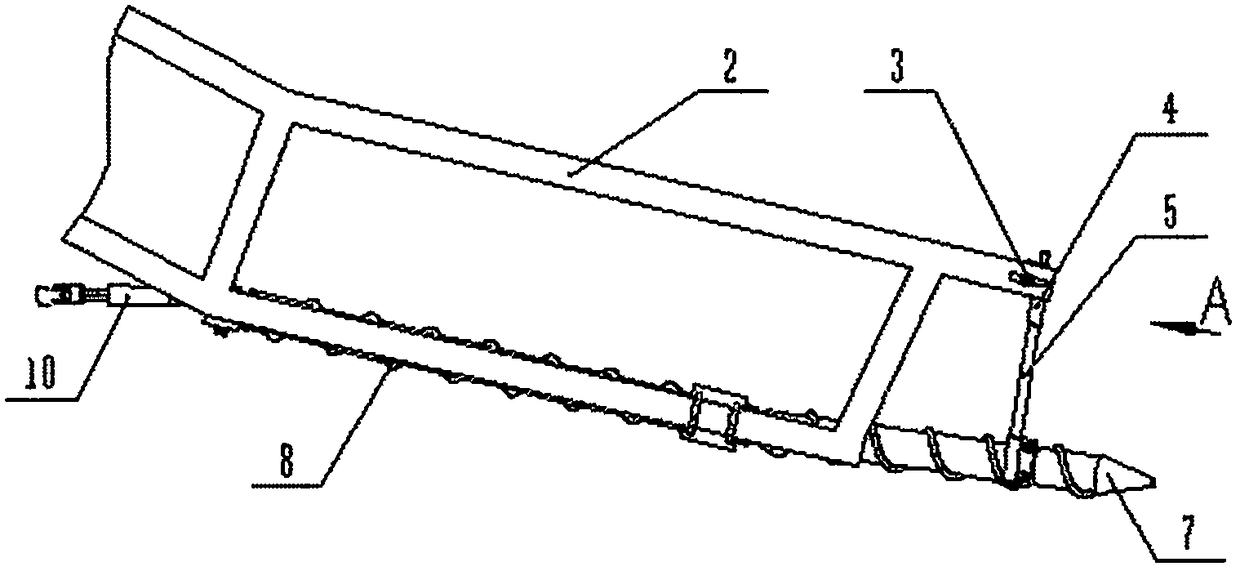

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A cabbage harvesting conveyor platform, equipped with an elastic mesh revolving crimping belt assembly 1 on the upper side of the platform 2, located below the elastic reticulated revolving crimping belt assembly 1 on the lower rear side of the platform 2 The rotary conveyor belt assembly 11 is installed at the position, and the front bracket 15 and the rear bracket 16 are fixed sequentially from front to back on the lower part of the front side of the platform 2, and the left side and the right side of the front bracket 15 and the rear bracket 16 The side parts are rotatable and parallel to each other to support and install the left-handed clamping and pulling conveying shaft 13 and the right-handed clamping and pulling conveying shaft 8 respectively. 8 is in an inclined configuration with the front low and the rear high. The input power universal trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com