Waterproof membrane edge scraping device

A waterproof roll material and edge scraping technology, applied in lamination, chemical instruments and methods, lamination auxiliary operations, etc., to achieve the effect of preventing burns, avoiding whitening, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

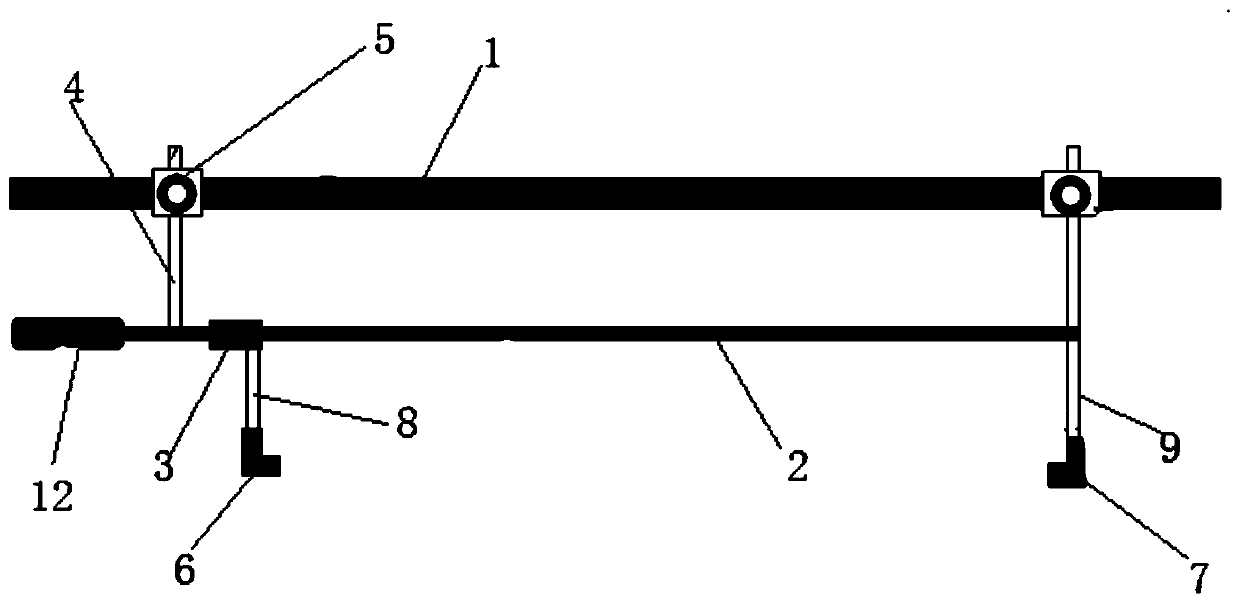

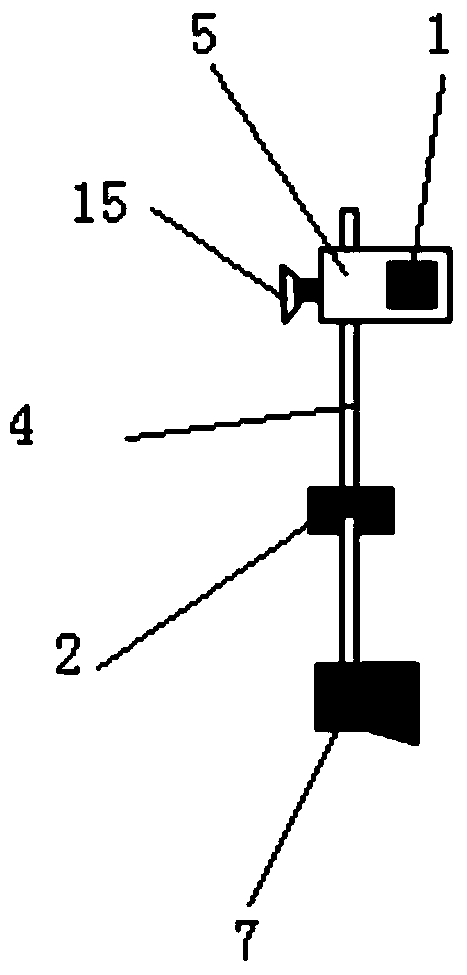

[0051] figure 1 Shows the front view of the waterproof membrane edge scraping device in one embodiment of the present invention, figure 2 It shows a side view of the waterproof membrane edge scraping device in one embodiment of the present invention, image 3 A schematic diagram of the scraping structure in one embodiment of the present invention is shown.

[0052] Such as Figure 1 to Figure 3 As shown, a waterproof membrane edge scraping device according to this embodiment includes:

[0053] Fixed rod 1, fixed rod 1 is arranged perpendicular to the direction of incoming coil material, and is arranged in parallel downstream of the thickness-fixing device; a pair of adjusting parts 5, a pair of adjusting parts 5 are sleeved on the two ends of fixed rod 1, and can be arranged along The length direction of the fixed rod 1 moves; the base ruler 2, the base ruler 2 is arranged below the fixed rod 1, arranged in parallel with the fixed rod 1, and connected with a pair of adjust...

Embodiment 2

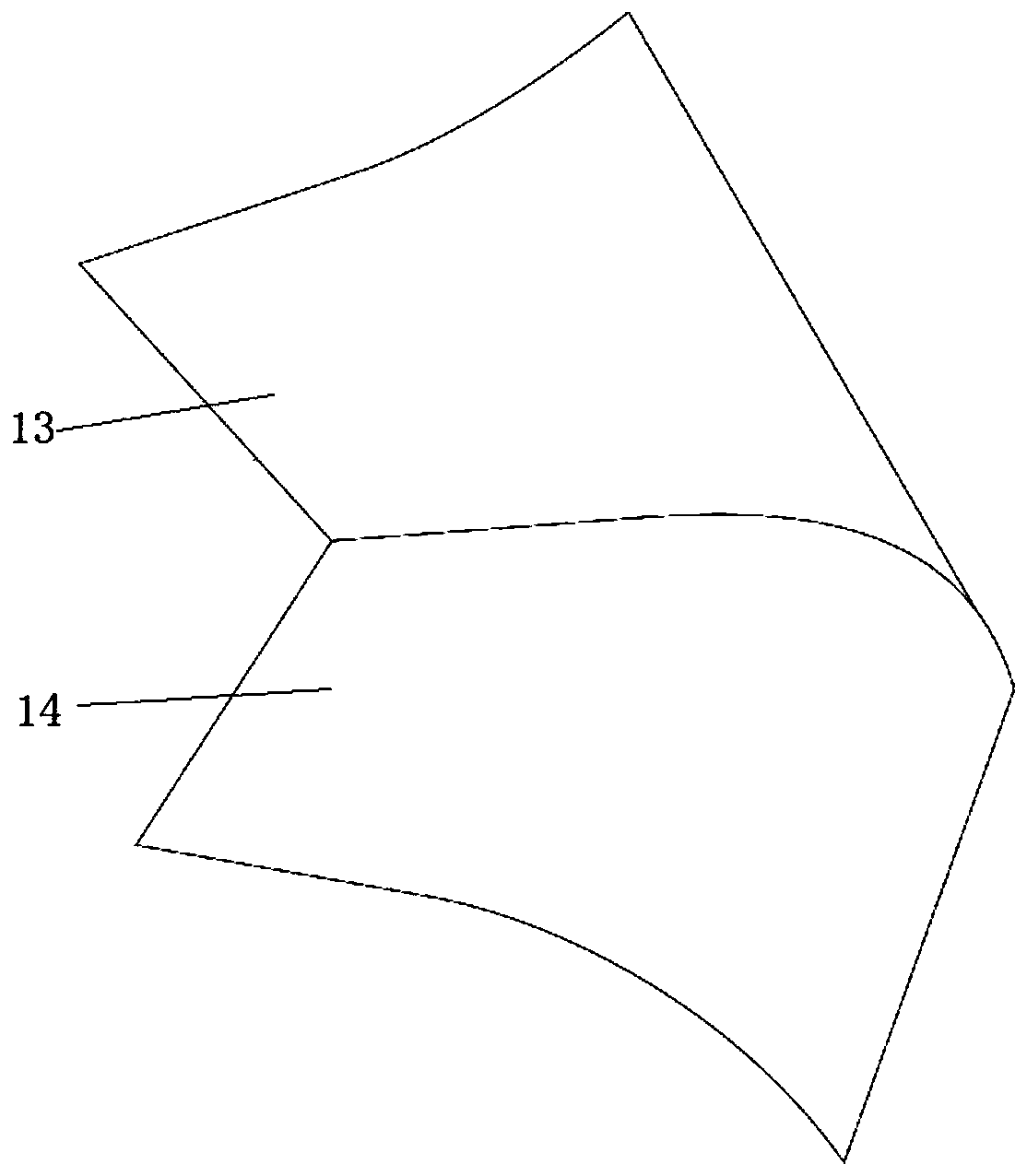

[0060] image 3 A schematic diagram of the scraping structure in one embodiment of the present invention is shown.

[0061] Such as image 3 As shown, the first scraping edge 6 and the second scraping edge 7 both include intersecting first side and second side, the first side 13 and the second side 14 are perpendicular to each other, and the size is 50mmx50mm (ignoring the thickness of the scraping edge) ; The first side 13 is a curved surface, one end is arranged along the vertical direction, and the other end is bent towards the outside of the waterproof coiled material edge scraping device, and the second side 14 is a curved surface, and one end is arranged along the horizontal direction, and the other end is arranged along the horizontal direction. The vertical direction is bent downwards, and the other end of the second side 14 faces the incoming direction of the coil.

[0062] In the waterproof coiled material production line, the coiled material enters the coiled mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com