Pallet robot

A pallet robot and pallet technology, applied in the field of intelligent robots, can solve problems such as increasing operation steps and operating costs, and reducing operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

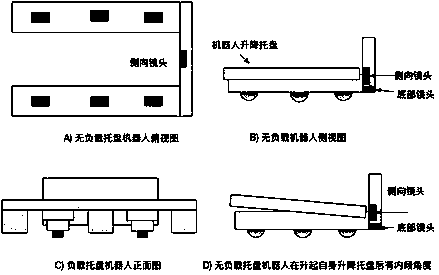

[0017] Such as figure 1 As shown, the pallet robot is composed of a pallet fork arm structure, a walking drive, a lifting platform, a main control panel, a detection lens, an obstacle sensor and a rechargeable battery. The pallet robot has two protruding forks to access the bottom of the pallet to lift the load. In terms of drive, the pallet robot is driven by two main wheels placed in the middle. Can be forward, backward and rotated. The two fork arms of the pallet robot each have a small lifting platform. Controlled by the built-in computer, the two lifting platforms can be raised or lowered simultaneously to lift the pallet. The two lifting platforms have an inward angle after being raised.

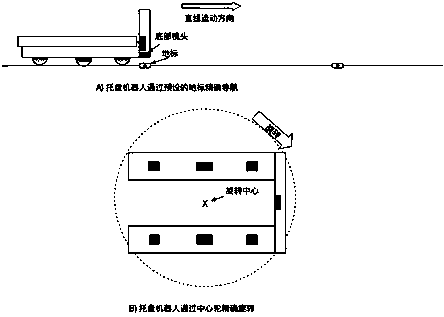

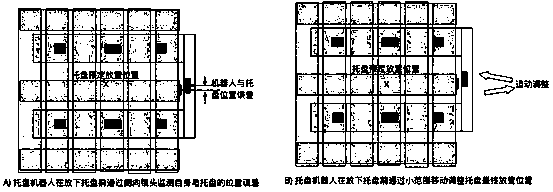

[0018] Such as figure 2 As shown in the figure, after receiving the task instruction from the central system, the pallet robot travels to the designated location accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com