Intelligent wire arranging system

A cabling and intelligent technology, applied in the field of intelligent cabling system, can solve problems such as hidden safety hazards, redundant staffing, and high operation intensity, and achieve the effect of avoiding hidden safety hazards, optimizing staffing, and saving floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A better understanding of the nature and advantages of the present invention may be obtained by reference to the following detailed description and accompanying drawings.

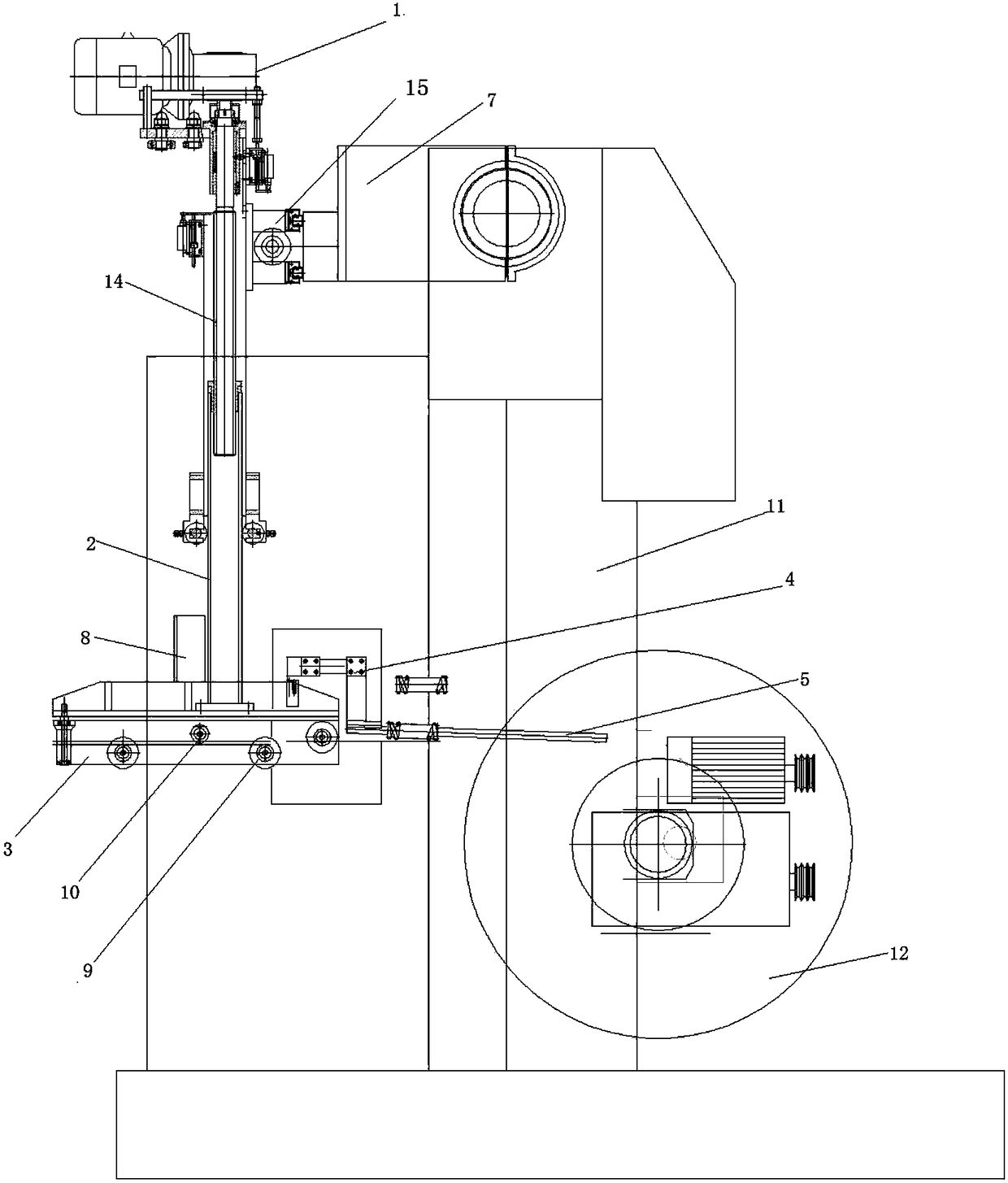

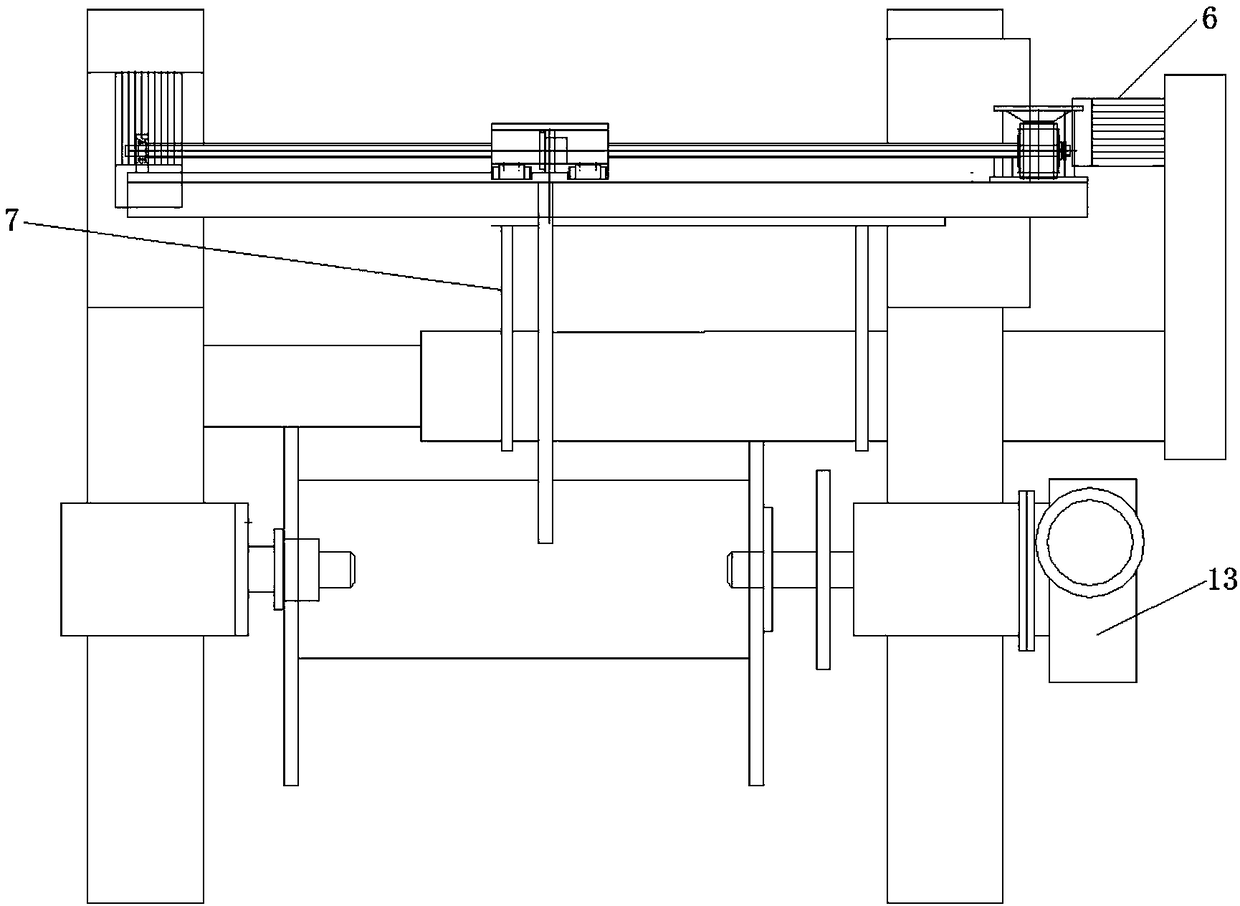

[0031] figure 1 It shows an intelligent cable arrangement system, the take-up part and the take-up part, the take-up part includes a take-up rack 11 and a take-up tray tool 12, the take-up tray tool 12 is controlled to rotate by a take-up motor 13, and the cable take-up part is installed At the upper end of the take-up frame 11, the cable part includes:

[0032] The cable unit 3 is used to introduce the optical cable into the manipulator unit 5;

[0033] The manipulator 5 unit includes the manipulator 5, the X-axis adjustment device and the Y-axis adjustment device. The cable arrangement manipulator 5 is perpendicular to the tray 12 and drives the cable arrangement horizontally.

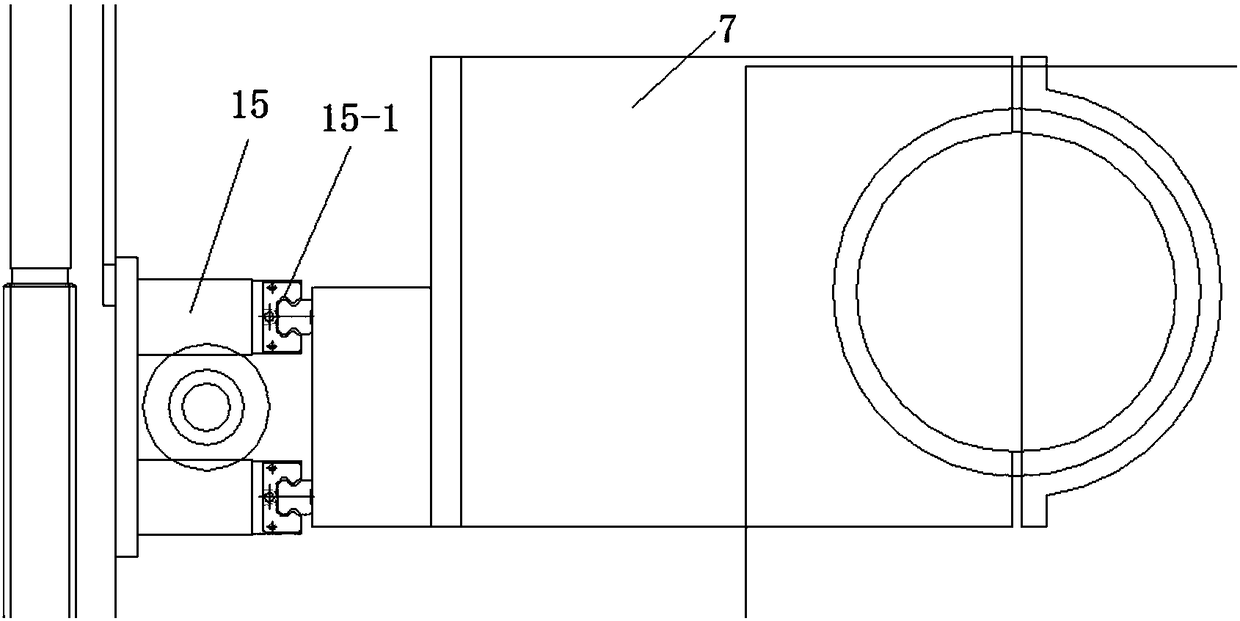

[0034] The feedback compensation unit, including the sensor 4 installed on the manipulator 5, is composed of two sets o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com