Protective sleeve volume fracturing pipe string

A volumetric fracturing and casing protection technology, which is applied in the field of fracturing strings, can solve problems such as weak bonding between the main body of the sandblasting machine and the upper joint, loose installation of the main body of the sandblasting machine and the nozzle, and potential safety hazards. Achieve the effect of reducing equipment volume, reducing impact and improving fracturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

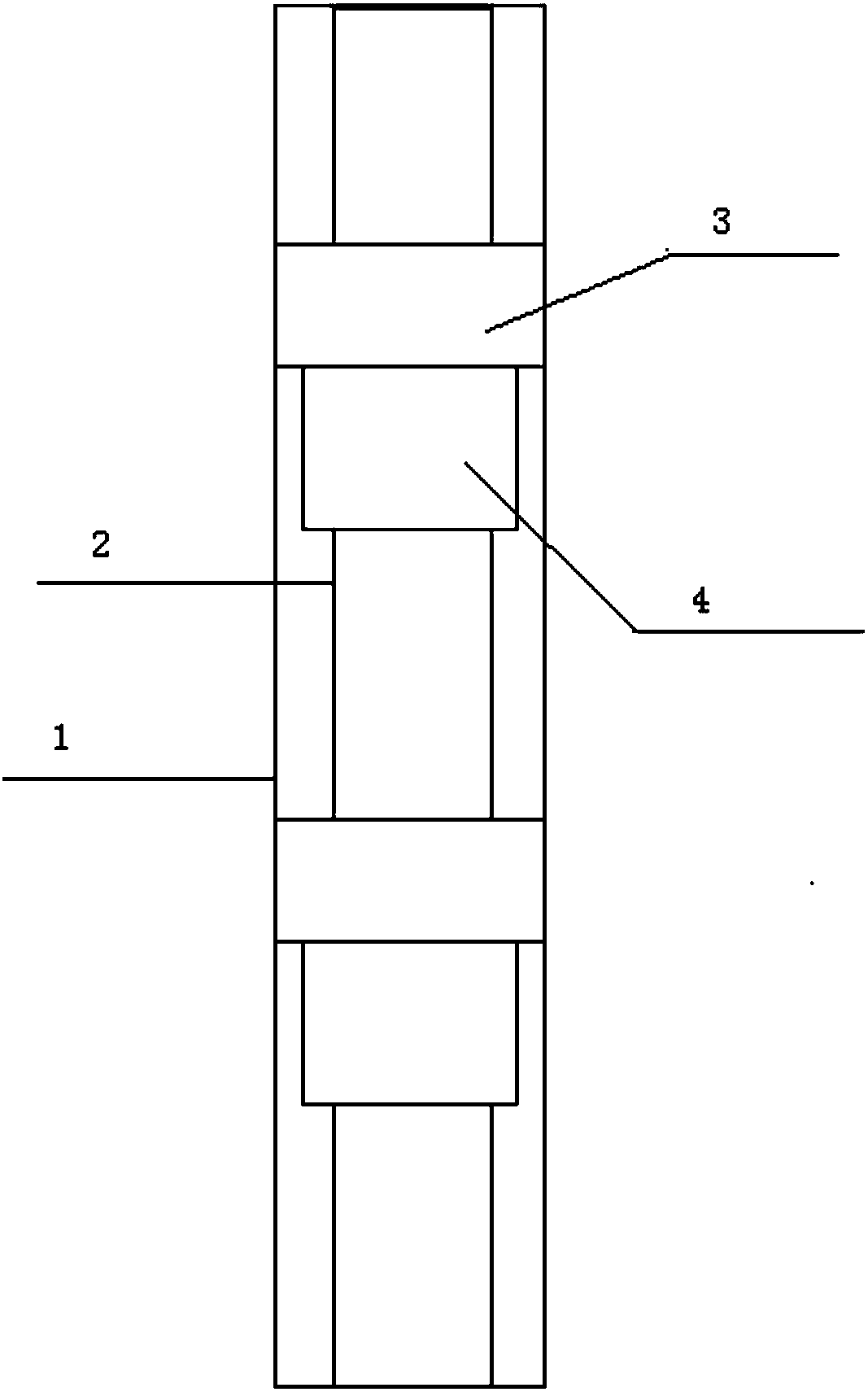

[0017] A protective casing volume fracturing string, including casing 1 and tubing 2, such as Figure 1-Figure 3 As shown, it also includes an anchor packer 3 and a self-sealing sand blaster 4;

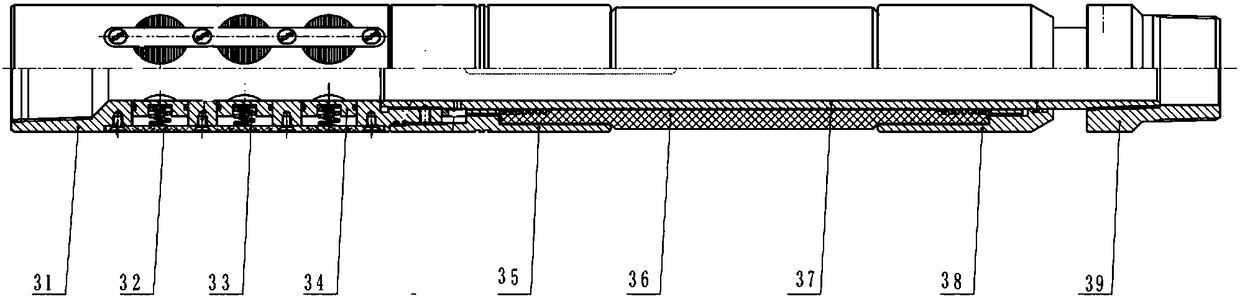

[0018] The anchor packer 3 includes a packer main body, and also includes an upper joint 31, a pressure plate 32, a spring 33, an anchor block 34, an upper rubber cylinder seat 35, a rubber cylinder 36, a central pipe 37, and a lower rubber cylinder seat 38 and the lower joint 39; the upper joint 31 and the lower joint 39 are respectively fixed at both ends of the packer main body, and the rubber cylinder 36 passes through the upper rubber cylinder seat 35 and the lower rubber cylinder seat 38 fixed on the outside of the packer body, the anchor block 34 is set in the opening at the top of the packer body, the pressure plate 32 and the anchor block 34 are connected by the spring 33, The central pipe 37 is arranged inside the main body of the packer;

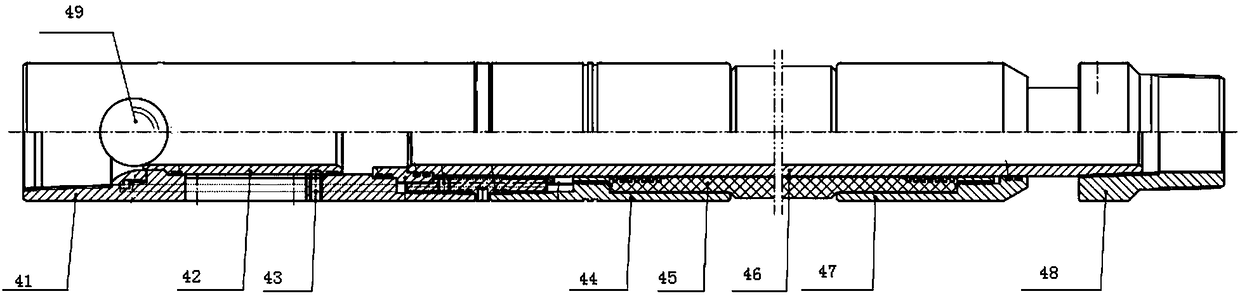

[0019] The self-styled sand blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com