Integral transverse moving method for tunnel lining trolley split trolley device

A technology for lining trolleys and split trolleys, which is applied in tunnel linings, tunnels, shaft linings, etc., can solve the problems of extended construction schedule, difficulty, and extended construction period expenses, so as to ensure construction quality, save costs, and speed up construction. The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

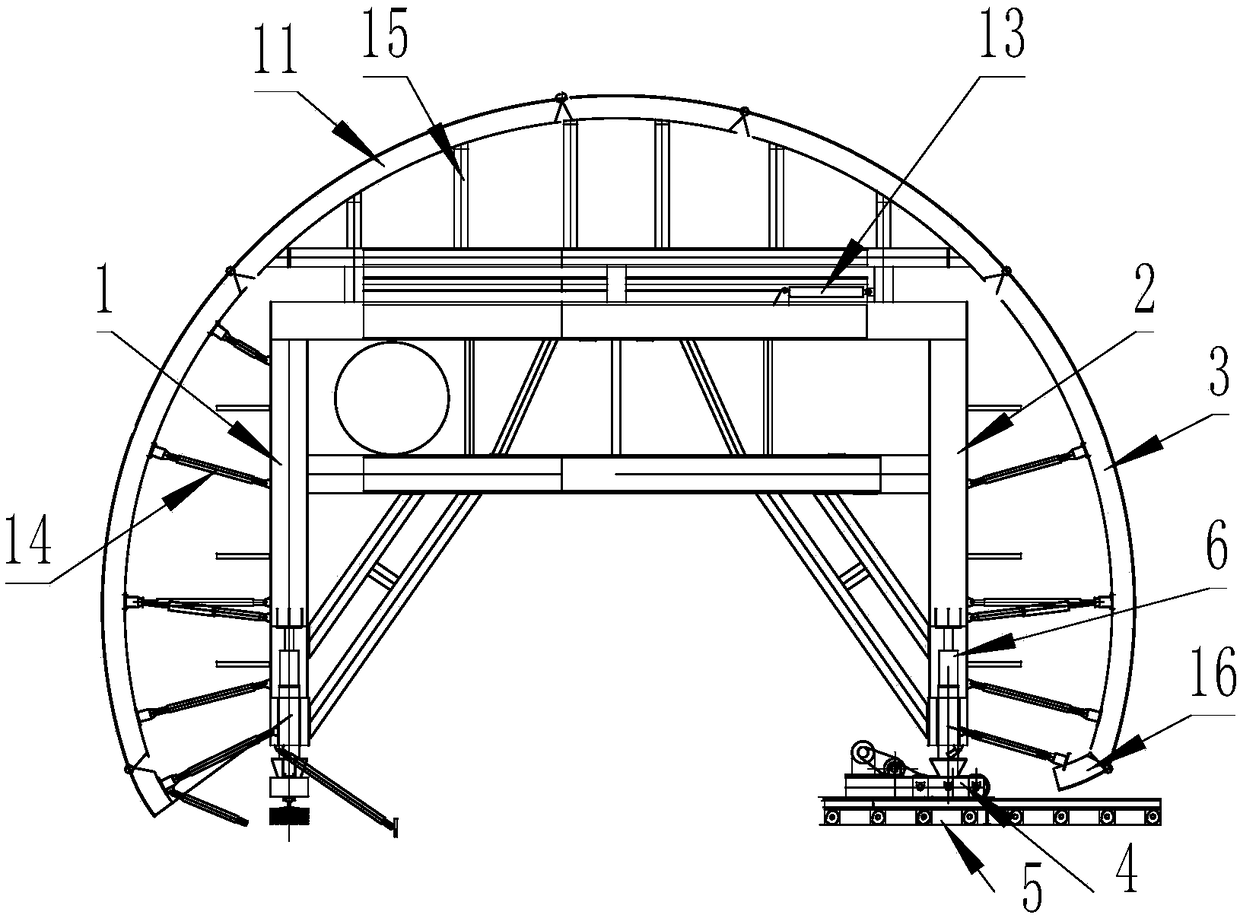

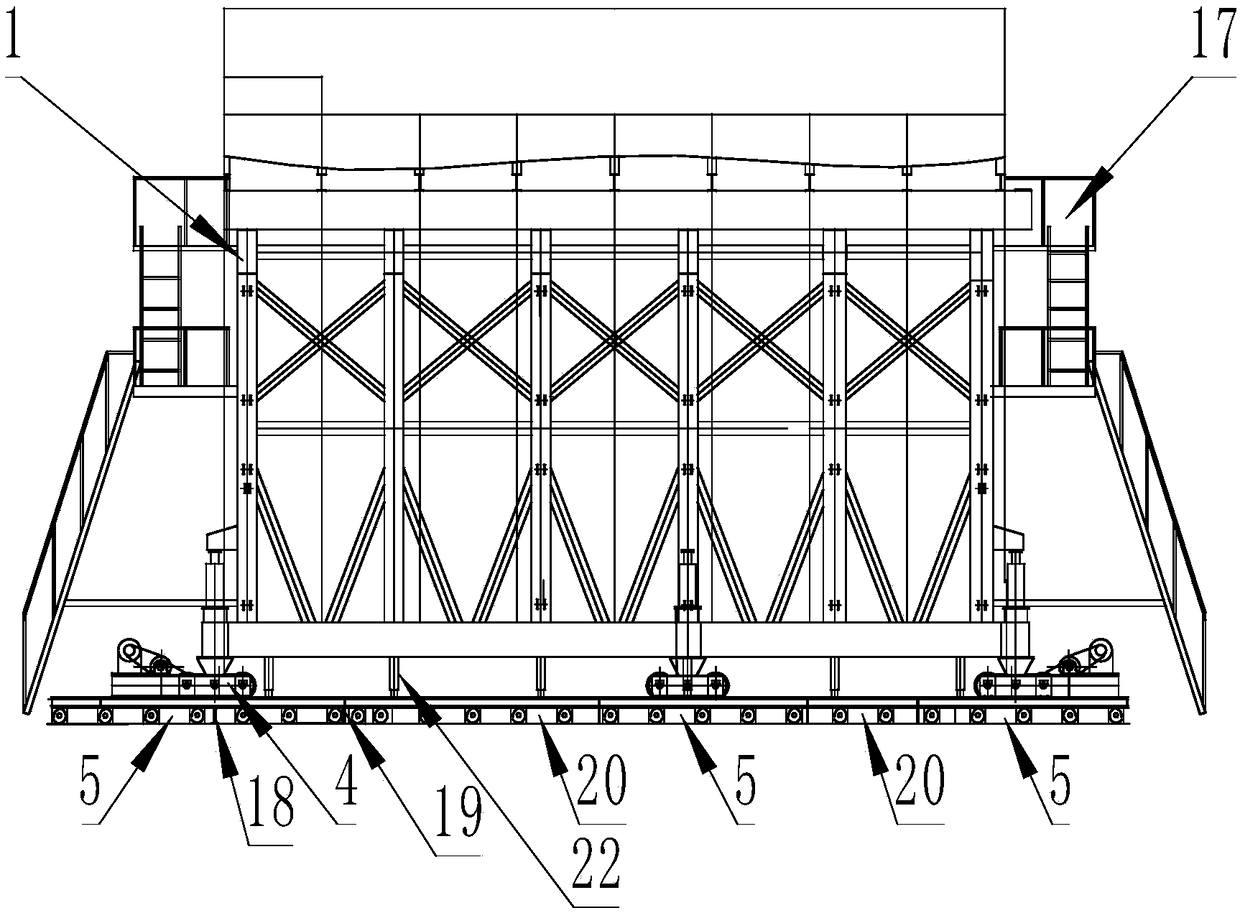

[0022] The tunnel lining trolley split trolley device is equipped with at least three trolley door frames. 1. The upper part, the middle part and the lower part of both sides of the trolley traversing gantry body 2 are respectively connected with three fluxes, and the front and rear ends of the trolley gantry body are respectively provided with escalators 17; the front and rear ends of the trolley fixed gantry body 1 1. The lower end of the trolley traversing gantry body 2 is respectively provided with a lifting device 4, and the lifting device 4 at the lower end of the trolley traversing gantry body 2 is set as a rotating lifting device 4, and the lifting and lowering of the trolley traversing gantry body 2 Between the walking device 4 and the ground, a walking track 20 is set in sections, a rotating track 5 is arranged between the walking track 20 segments, a rotating track interface 19 is set between the walking track 20 and the rotating track 5, and the lifting walking devi...

Embodiment 2

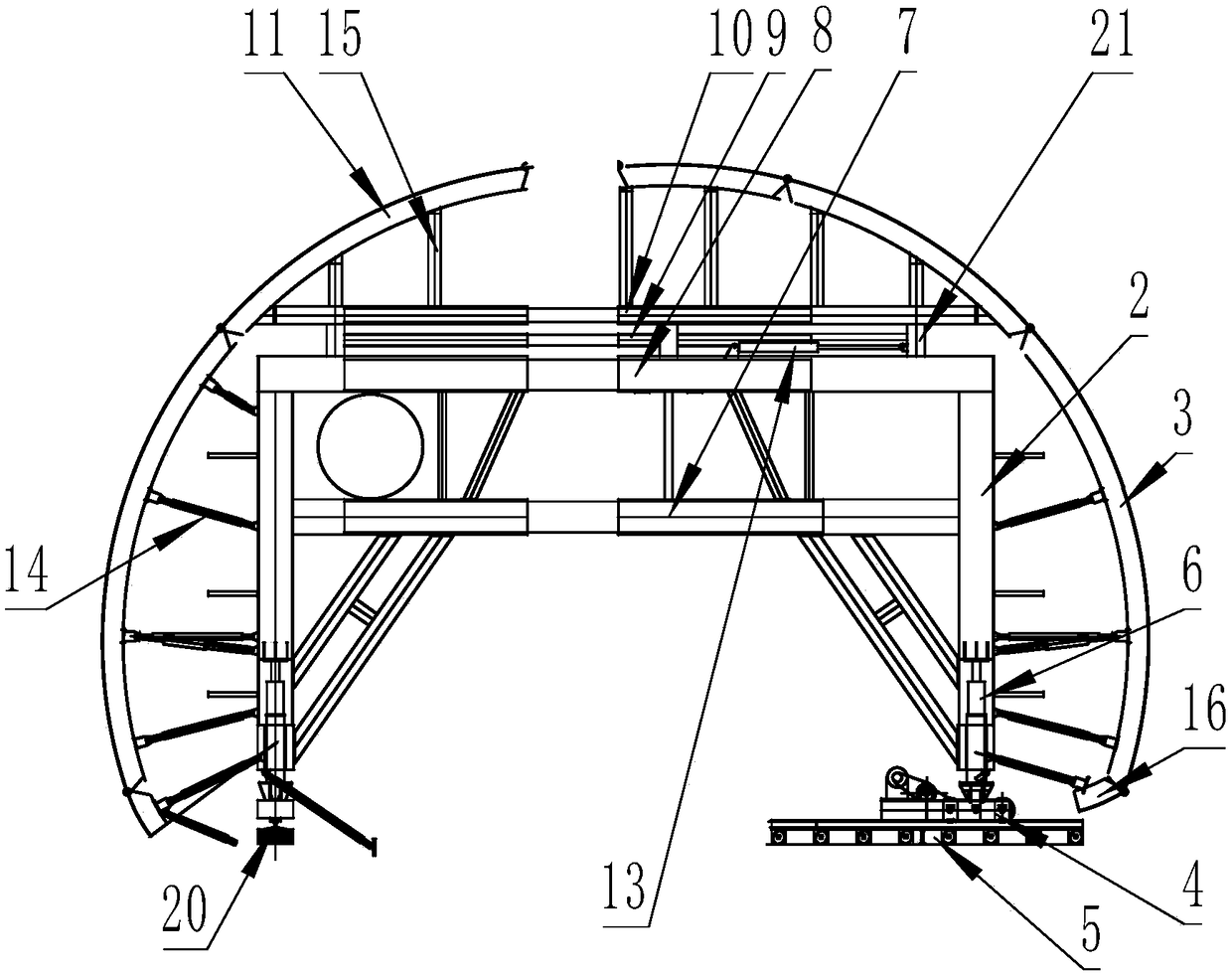

[0029] After the rotary lifting device 4 at the lower end of the trolley traversing the door frame body 2 and the rotating track 5 are rotated 90° outward, the frame body traversing oil cylinder 13 passes through the hydraulic pump, and the rotary lifting device 4 starts to pull the trolley through the driving device at the same time. The traversing gantry body 2 runs outward synchronously, and the side of the trolley traversing the gantry body 2 drives the casing lower beam 7, the casing gantry beam 8, the traversing casing beam 9, and the outer layer of the top mold beam 10 The pipes slide outwards simultaneously with the inner pipe as the sliding shaft.

Embodiment 3

[0031] The outer pipe slides outwards to the preset position at the same time and then stops. The widening template 12 is installed in the mobile interface reserved for the split top mold 11, and the rotating lifting walking device 4 and the rotating track 5 are reversely rotated for 90 degrees according to the original rotation process. °Enter the expanded position and stop, move the walking track 20 to correspond to the rotating track 5 and then become the new expanded walking track; complete the overall lateral movement of the tunnel lining trolley split trolley device and the complete split top form 11, separate Carry out the lining construction of the tunnel after the top formwork 11 is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com