Hydraulic Performance Prediction Method of High Power Centrifugal Pump Based on Weakly Compressible Flow Analysis

A technology of flow analysis and hydraulic performance, which is applied to the components of pumping devices for elastic fluids, radial flow pumps, pumps, etc. complex problems, to achieve the effect of accurate numerical prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

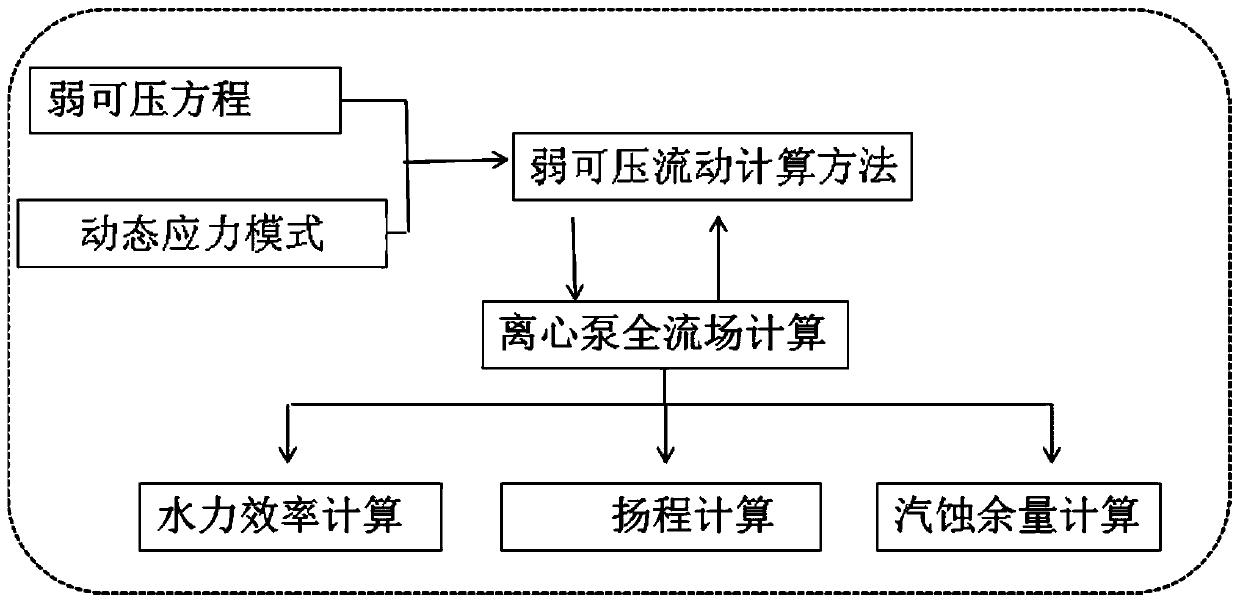

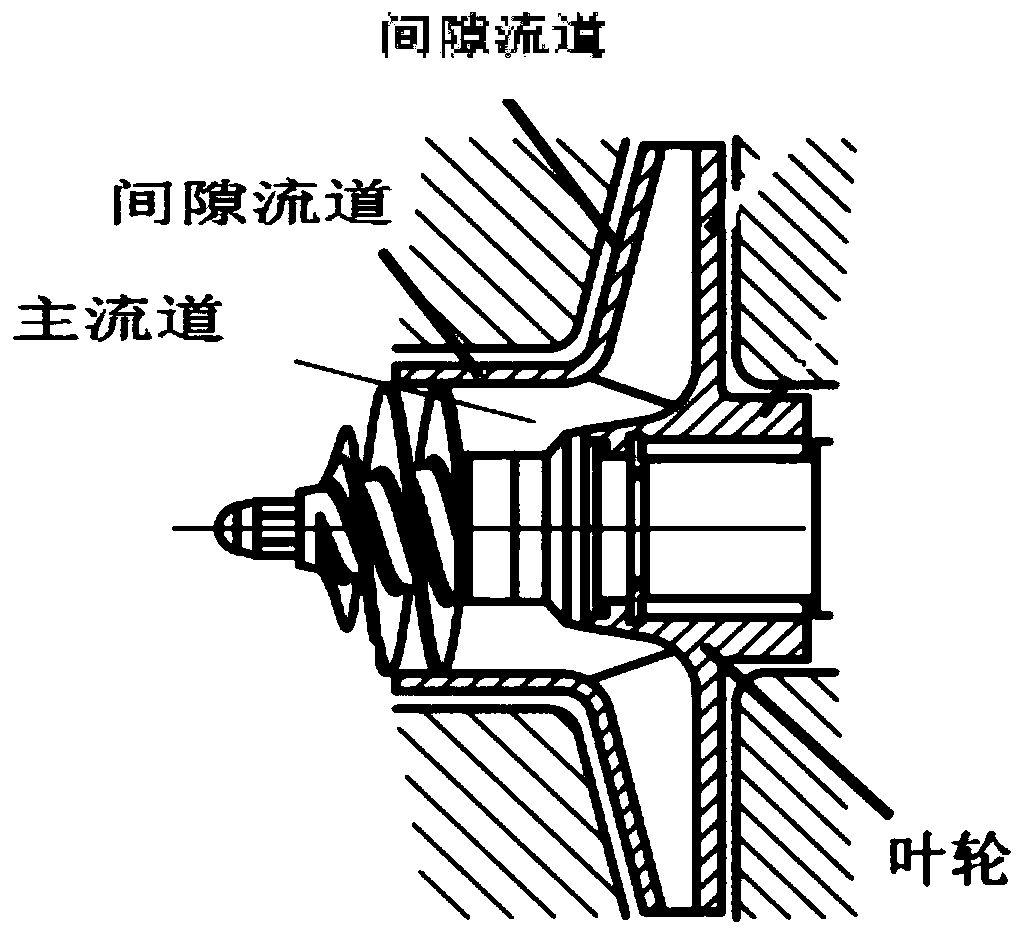

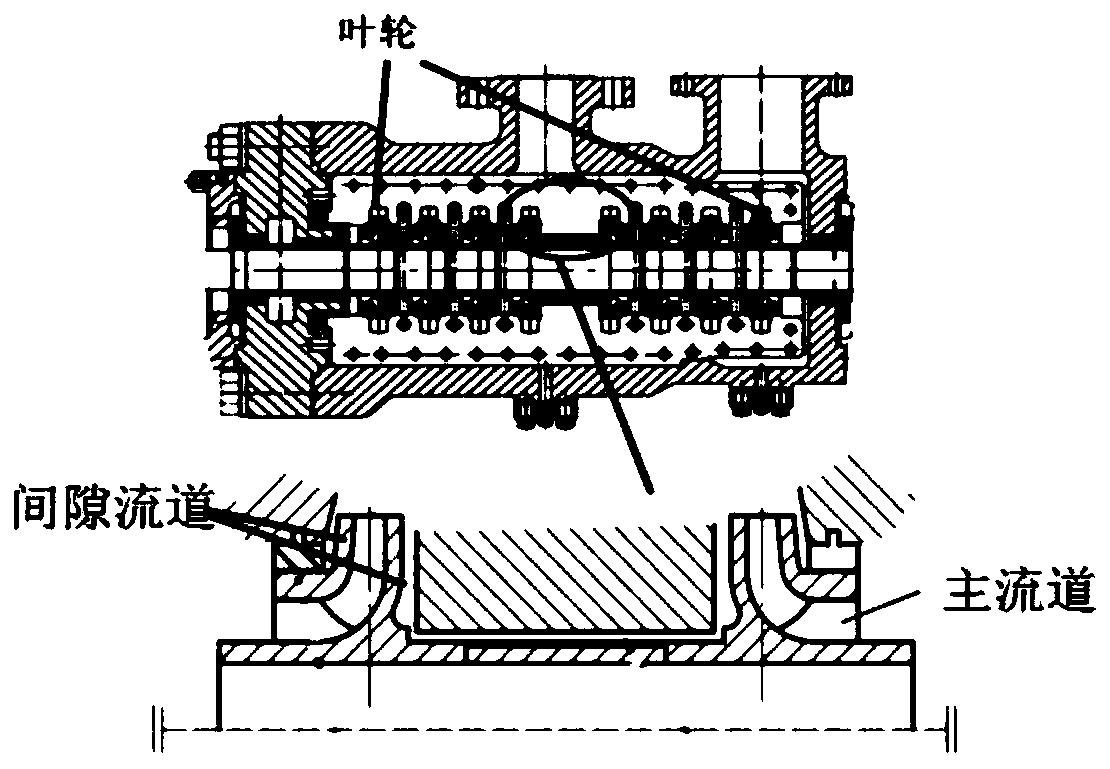

[0051] Embodiment 1. A method for predicting the hydraulic performance of a high-power centrifugal pump based on weakly compressible flow analysis, such as Figure 1-5 As shown, firstly, the calculation method for the weakly compressible flow in the high-power centrifugal pump will be established, considering the weak compressibility of the liquid, and the velocity gradient and helicity constraints will be introduced into the LES sub-grid stress calculation formula to establish a new sub-grid The lattice stress model forms a complete numerical calculation method for internal flow of high-power centrifugal pumps considering weak compressibility. Finally, according to the calculation results of the full flow field, the hydraulic performance of the high-power centrifugal pump is calculated, and the hydraulic performance includes head, hydraulic efficiency and NPSH. Include the following steps:

[0052] 1) Establishment of weakly compressible flow calculation method;

[0053] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com