Frame splicing method based on cross sectional materials

A technology of cross-shaped and cross-shaped profiles, which is applied in the direction of thin plate connection, connection components, mechanical equipment, etc., can solve the problems of poor connection strength, low splicing efficiency, and difficult splicing, so as to reduce the difficulty of lapping and improve the reliability of impact resistance , the effect of increasing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

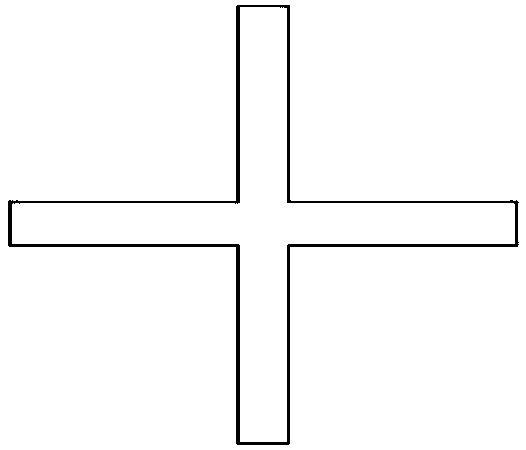

[0017] A kind of frame splicing method based on the cross profile of the present invention, such as figure 1 As shown, the base piece used in this splicing method is a long metal cross section with a cross-shaped cross section, and at least one end of the cross section has a positioning gap inward along a group of parallel sides;

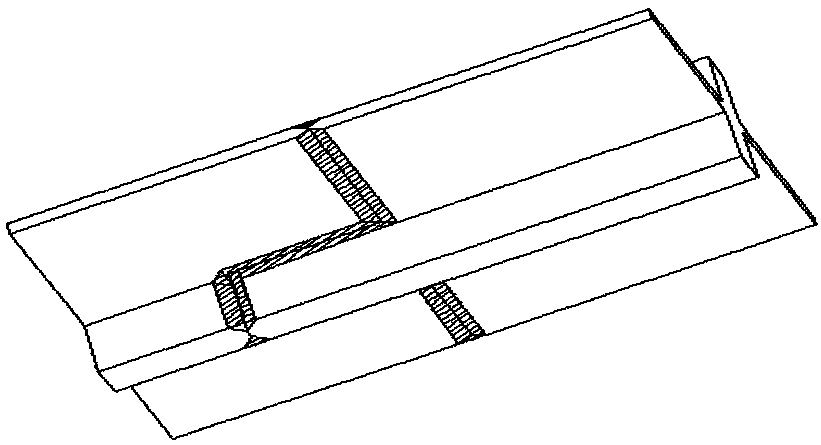

[0018] When the two cross profiles are overlapped end to end, the two cross profiles have a positioning gap and one end is mortise and tenon butt joint and welded, and the two cross profile mortise and tenon joints are processed with welding grooves, such as figure 2 shown;

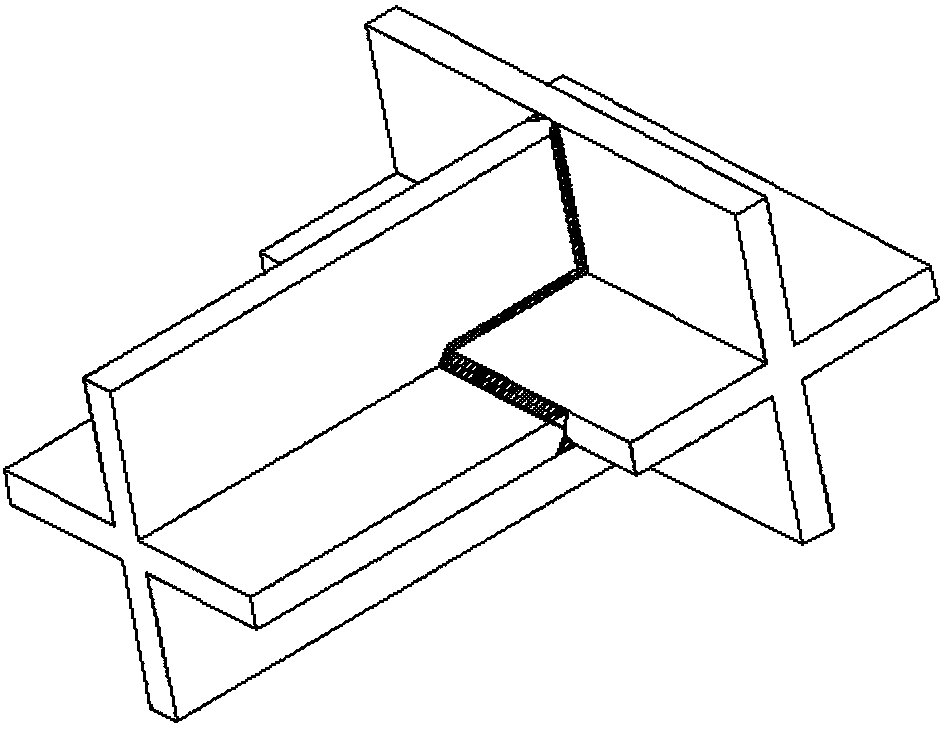

[0019] When the two cross profiles intersect and overlap, one end of the left cross profile with a positioning gap is mortised and tenon-jointed with the side of the right cross profile and fixed by welding, and the inner side of the left cross profile positioning gap is processed as a straight line parallel to the end surface of the cross profile edge, and the mortise and te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com