Layered contact type instant freezer

A quick-freezer and contact technology, applied in the field of quick-freezers and contact-type quick-freezers, can solve the problems of slow refrigeration and quick-freezing, low freezing rate, and large volume, and achieve convenient access, large freezing contact area, and high freezing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

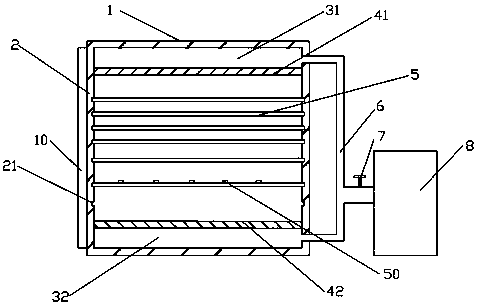

[0019] Such as figure 1 As shown, it is a specific embodiment of the layered contact quick-freezing machine described in the application of the present invention. In this embodiment, the quick-freezing machine includes a hollow body 1, and the side of the body 1 is provided with a cover plate 10, and the cover The plate 10 is hinged with the shell of the body 1, and the outer peripheral cold plate 2 mounted on the inner wall of the body is arranged in the body 1, and two freezing chambers are arranged at the upper and lower ends of the outer peripheral cold plate 2, which are respectively the first freezing chamber 31 and the second freezing chamber 32, the first freezing chamber 31 has a first partition 41, and the second freezing chamber 32 has a second partition 42, and the first freezing chamber 31 and the second freezing chamber 32 are connected to each other through a connecting pipe 6. The refrigerating unit 8 outside the body is connected, the connecting pipe 6 is prov...

Embodiment 2

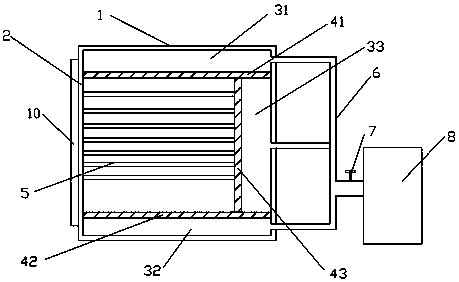

[0023] Such as figure 2 Shown is another specific embodiment of the layered contact quick-freezing machine described in the application of the present invention. In this embodiment, the quick-freezing machine includes a hollow body 1, and a cover plate 10 is provided on the side of the body 1. The cover plate 10 is hinged with the shell of the body 1, and the outer peripheral cold plate 2 mounted on the inner wall of the body is provided in the body 1, and three freezing chambers are arranged at the upper and lower ends and one side of the outer peripheral cold plate 2, respectively. It is the first freezing chamber 31, the second freezing chamber 32 and the third freezing chamber 33. The first freezing chamber 31 has a first partition 41, the second freezing chamber 32 has a second partition 42, and the third freezing chamber 33 has a first partition 41. Two dividing plates 43, the first freezing chamber 31, the second freezing chamber 32 and the third freezing chamber 33 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com