Multi-channel MEMS (Micro-Electro-Mechanical System) gyroscope calibration test data collection device and collection method

A test data and acquisition device technology, applied in the field of multi-channel MEMS gyroscope calibration test data acquisition device, can solve the problems that the evaluation test board is unfavorable and unsuitable for the gyroscope temperature compensation calibration data acquisition system, too many cables, etc. Application value and promotion prospects, the effect of reducing data sampling cost and improving data sampling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

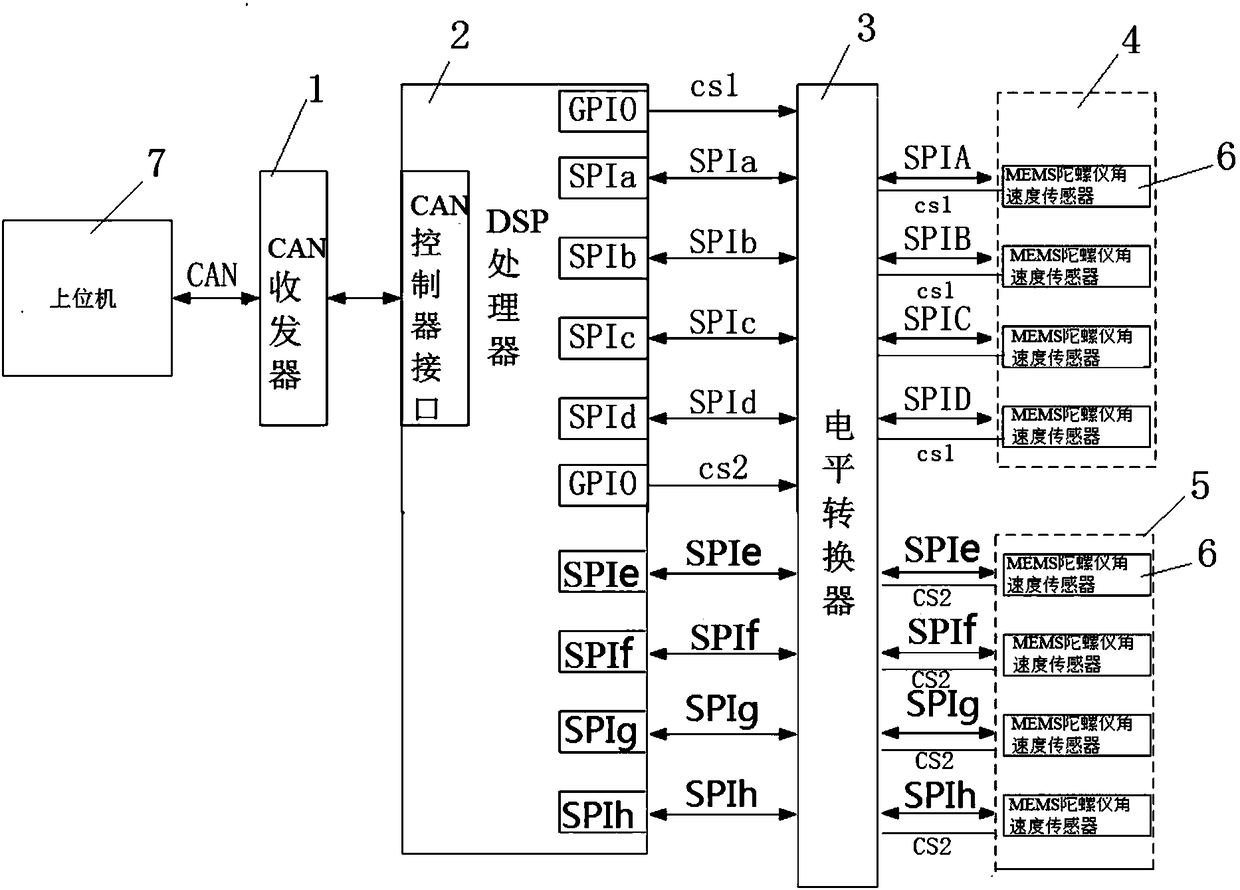

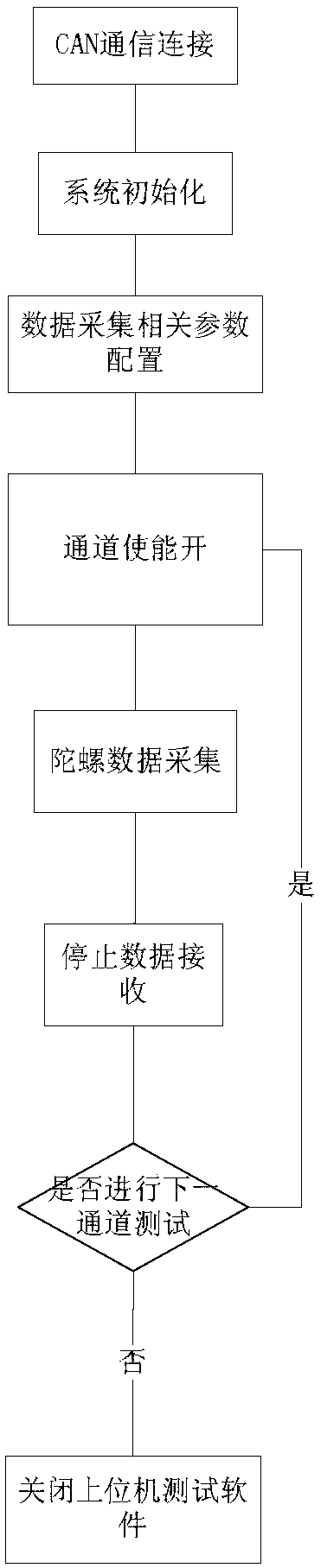

[0023] A multi-channel MEMS gyroscope calibration test data acquisition device designed by the present invention includes a CAN transceiver 1, a DSP processor 2, a level converter 3, a first MEMS gyroscope angular velocity sensor group 4 and a second MEMS gyroscope Meter angular velocity sensor group 5, described first MEMS gyroscope angular velocity sensor group 4 and the second MEMS gyroscope angular velocity sensor group 5 all comprise a plurality of MEMS gyroscope angular velocity sensors 6, the upper computer communication interface of described CAN transceiver 1 is used Because the CAN communication interface of the upper computer 7 (computer) is connected through the CAN bus, the processor communication interface of the CAN transceiver 1 is connected to the CAN controller interface of the DSP processor 2 through the CAN bus; because the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com