Multi-station high-precision quantitative weighing device

A quantitative device, high-precision technology, applied in measuring devices, weighing, weighing equipment with special properties/forms, etc. The effect of waste, saving labor cost, and improving the accuracy of weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

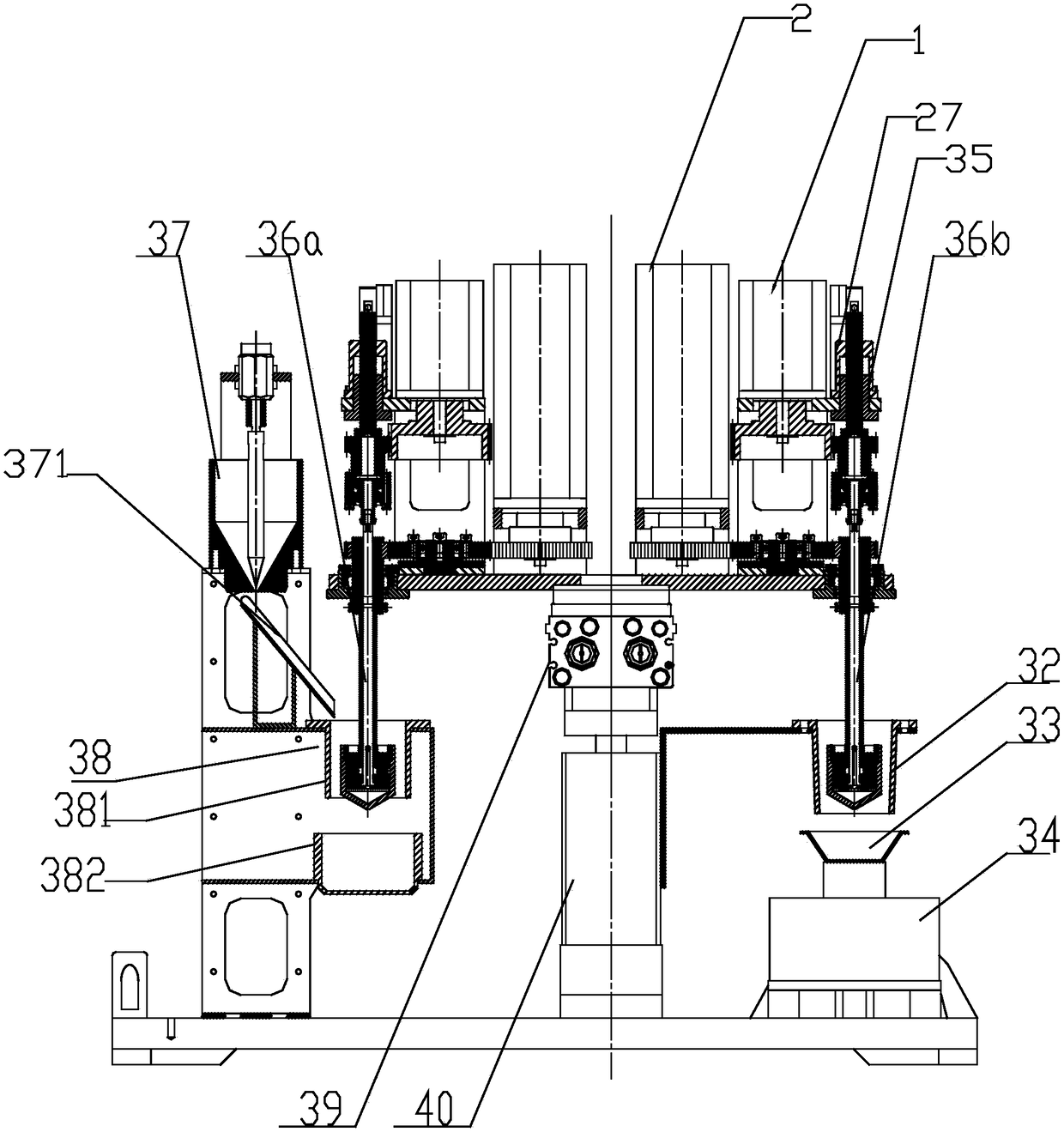

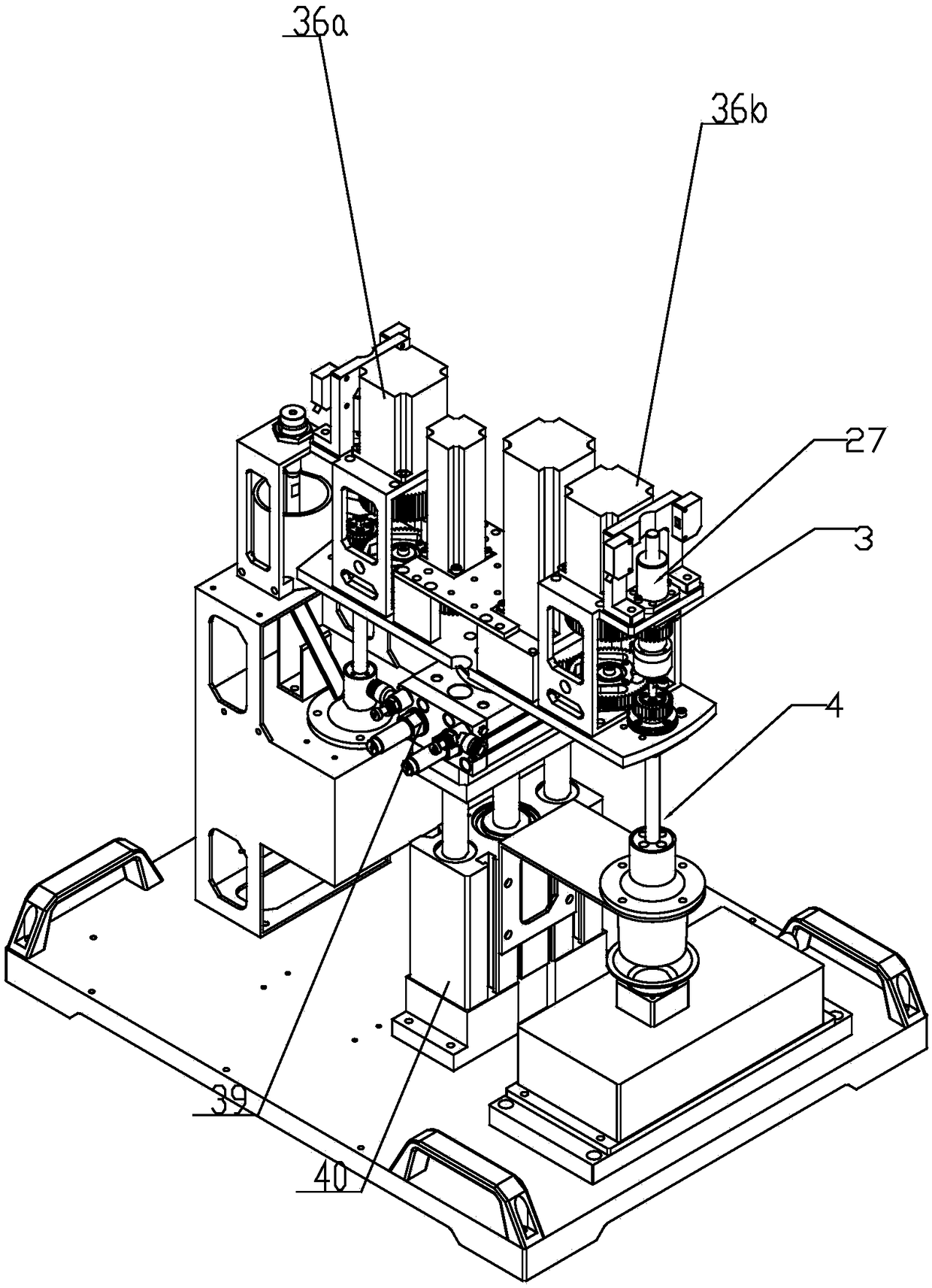

[0034] Such as figure 1 and 2 As shown, a multi-station high-precision weighing and quantifying device includes a feeding assembly, a feeding mechanism 37, a surplus material collecting assembly 38, a rotating device 39, a lifting device 40 and a weighing assembly, and the lifting device 40 is installed on the machine On the frame base, the upper end of the lifting device 40 is connected with the rotating device 39, and the rotating device 39 is connected with the feeding platform, and the feeding platform rotates with the rotating device 39, and the feeding platform rotates with the lifting device 40. Do lifting movement, several groups of feeding components are set on the feeding platform, the feeding mechanism 37 is arranged on the side frame on one side of the feeding platform, and the feeding mechanism 37 transports the powder to the feeding In the assembly, the residual material collection assembly 38 is arranged below the feeding mechanism 37, the weighing assembly is ...

Embodiment 2

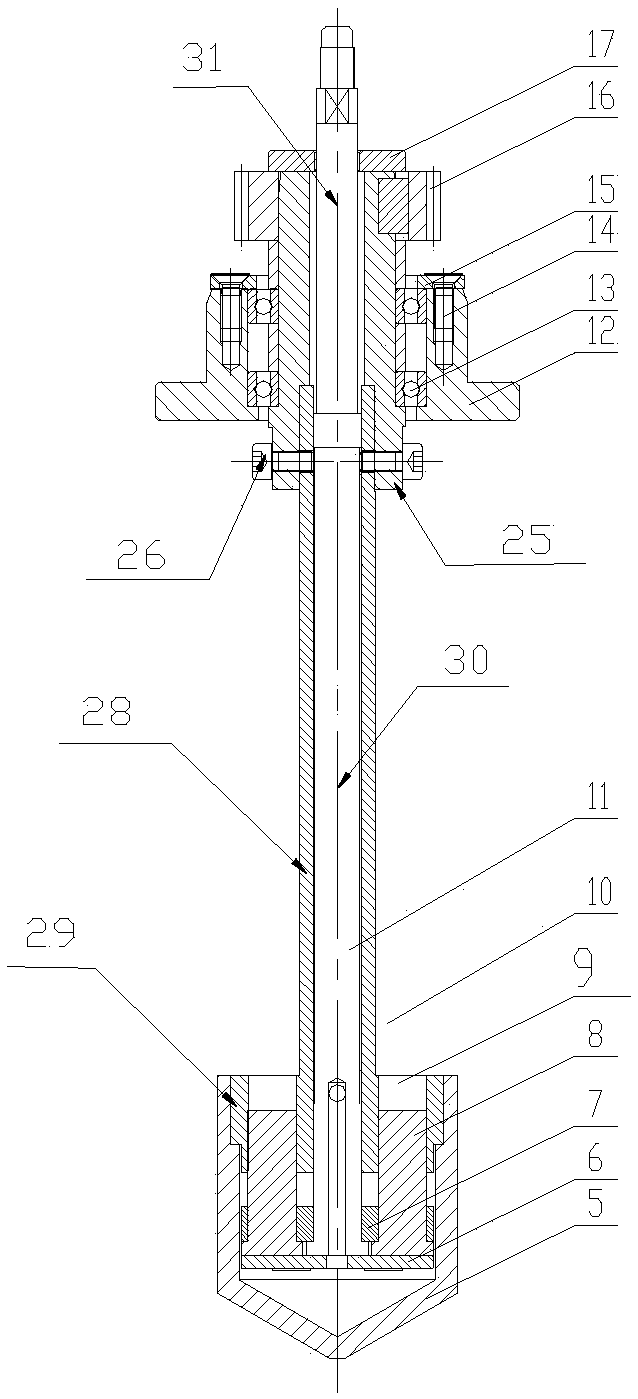

[0054] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. The spoon assembly 44 of this embodiment also includes a connecting shaft 25, the connecting shaft 25 includes a central hole 31, the central hole 31 is coaxial with the central cavity 30, and the connecting shaft 25 is fixedly connected with the first cup body 28 of the container cup 10 , there are many ways of fixed connection. In this embodiment, the connecting shaft 25 is fixedly connected with the first cup body 28 of the container cup 10 through screws 26. The cup bearing seat 12 and the first gear 16 are respectively connected to the rotating shaft 25. Fixedly connected, the cup bearing seat 12 is connected to the connecting shaft 25 through the bearing gland 15 and the bearing screw 14, and the connecting shaft 25 is placed in the cup bearing group 13. The purpose of this setting is to facilitate manufacturing, especially for...

Embodiment 3

[0056] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. The upper end of the first rod body 221 of the lifting rod 22 in this embodiment is provided with a helical gear, and the adjusting nut 27 in the guide assembly is provided with a meshing gear that cooperates with the helical gear, and the first drive assembly 1 drives the lifting rod 22 to rotate so that the lifting Rod 22 realizes lifting motion under the effect of helical gear.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap