Evaluation method for equipment manufacture supplier

An evaluation method and equipment manufacturing technology, which is applied in business, data processing applications, complex mathematical operations, etc., can solve problems such as the inability to guarantee scientificity, objectivity and accuracy, and single algorithms, so as to improve the evaluation management system and improve precision. level of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

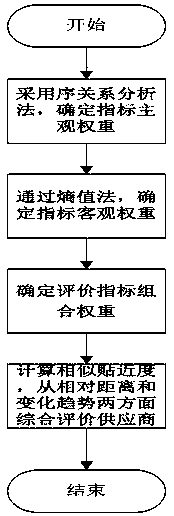

[0016] An evaluation method for equipment manufacturing suppliers, based on the sequence relationship analysis method, entropy value method, TOPSIS method and gray correlation degree analysis method for supplier evaluation, relying on historical data and model algorithms to improve the supplier evaluation management system and enhance supplier management Level of refinement; mainly includes the following two parts:

[0017] The first is index weight calculation. The order relationship analysis method is used to sort the indicators according to expert experience, and the entropy method is used to modify the index weights. The index weights are determined from both objective and subjective perspectives, and the shortcomings of the purely subjective and objective assignment methods are avoided.

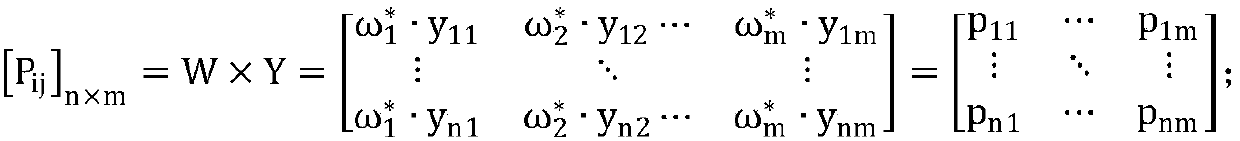

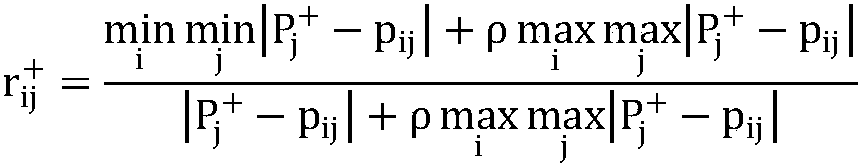

[0018] The second is the supplier evaluation method algorithm. According to the above calculation results, using the TOPSIS method and the gray relational degree analysis method as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com