Secure collapse teatcup liner

A milk cup and lining technology, applied in milking equipment, dairy products, applications, etc., can solve problems such as slow milking and insufficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

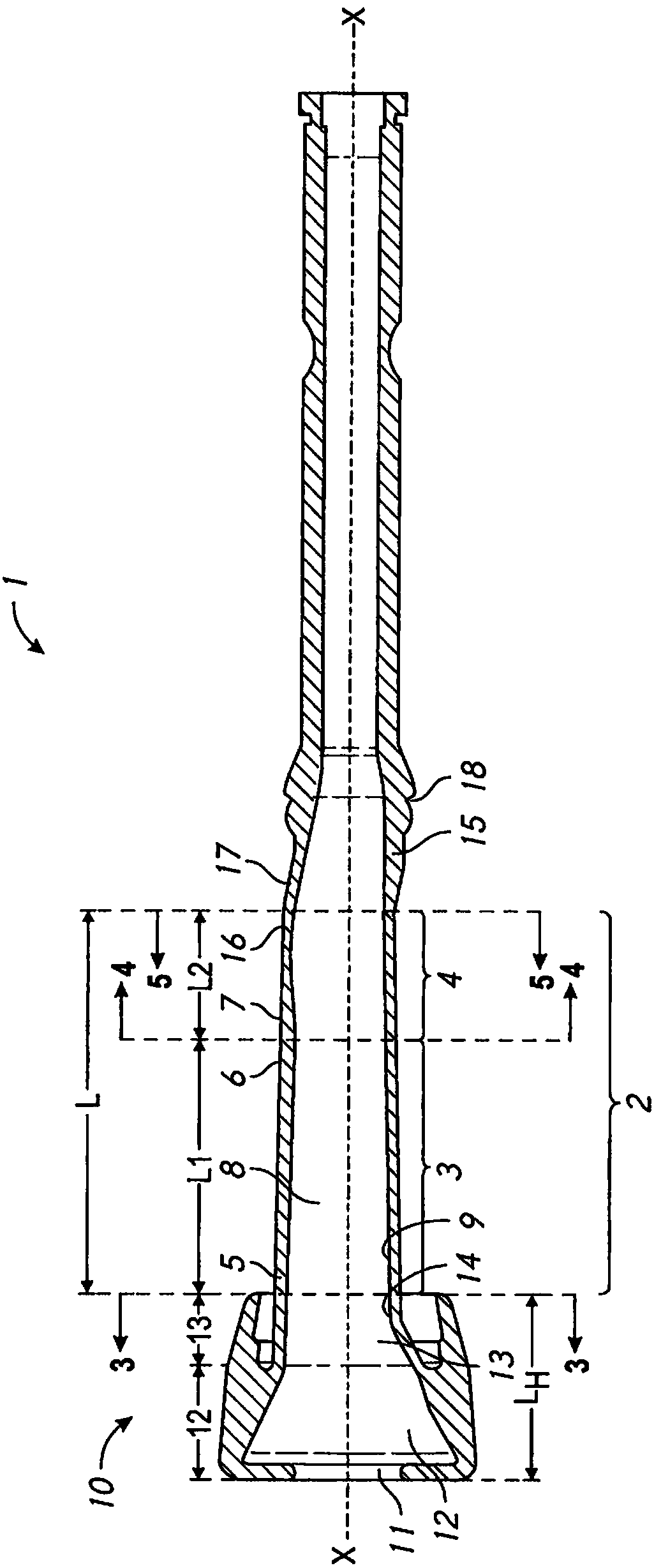

[0061] figure 2 A longitudinal cross-sectional side view of a first type embodiment of a teat cup liner 1 according to the invention is disclosed. As shown in the figure, the liner 1 has a longitudinal shape extending along a longitudinal axis (x).

[0062] In all embodiments of the present invention, the teat cup liner 1 includes a tube 2 with a polygonal cross-sectional shape composed of an upper tube 3 and a lower tube 4.

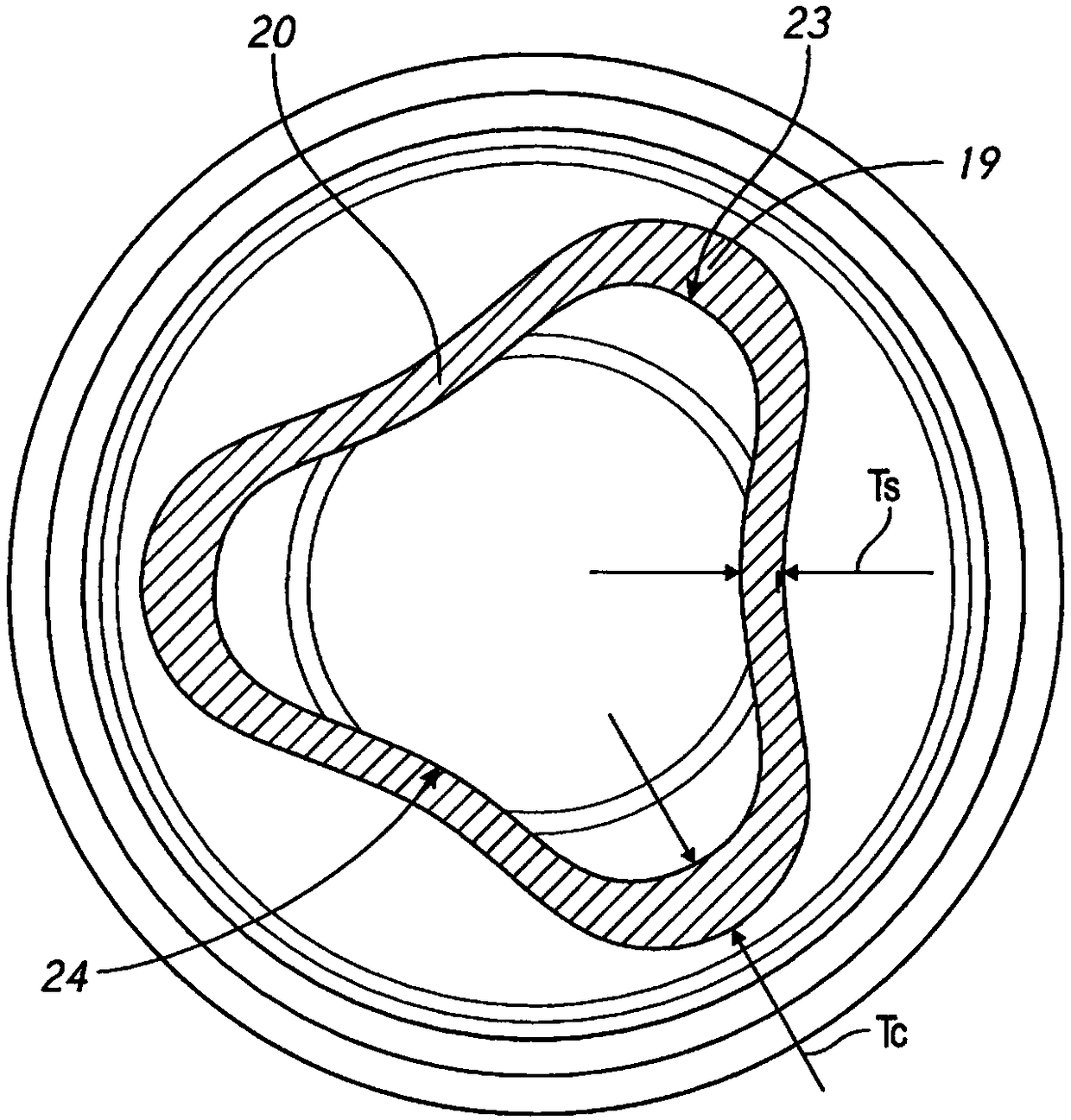

[0063] image 3 A polygonal cross-sectional view at the top 5 of the upper cylinder 3 along the section line 3-3 is shown. Figure 4 A polygonal cross-sectional view along the section line 4-4 is shown, in which the bottom part 6 of the upper cylinder 3 is connected to the top part 7 of the lower cylinder 4. Figure 5 A polygonal cross-sectional view along section line 5-5 is shown.

[0064] The barrel 2 defines an internal space 8 with an inner surface 9 which is used in the upper barrel 3 to receive teats.

[0065] The upper cylinder 3 has a first length (L1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com