Double operation machine for pulverizing soil and recovering residual film on hilly land

A technology for recycling residual film and operating machines, which is applied to agricultural machinery and tools, agriculture, shovels, etc. It can solve the problems of high operating cost, low rate of residual film pickup, soil compaction, etc., and achieve high operating efficiency, strong passing performance, The effect of low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

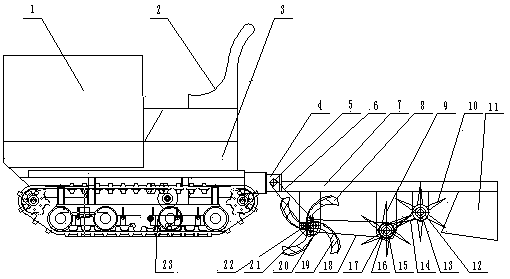

[0024] like figure 1 As shown in the figure, a compound working machine for recovering plastic residual film from crushed soil on hilly land includes a traveling device and a tool frame 7 mounted on the rear side of the traveling device. In the present embodiment, the traveling device includes a walking chassis 3, a walking crawler belt 23 is installed at the bottom of the walking chassis 3, and a diesel engine 1, a driver's seat 2 and a transmission box 4 are installed at the top of the walking chassis 3. Walking gear also can be other forms in the prior art.

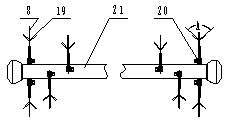

[0025] Three mutually parallel supports are installed successively from the front to the back below the tool frame 7, and the soil-crushing knife shaft 21, residual film recovery shaft 16, and residual film stripping shaft 13 are installed by rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com