Coating used on bearing of motor rotor

A technology for rotors and bearings, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as unusability, damage and danger, and cracking of the outer layer, and achieve the effects of convenient operation, increased service life, and strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

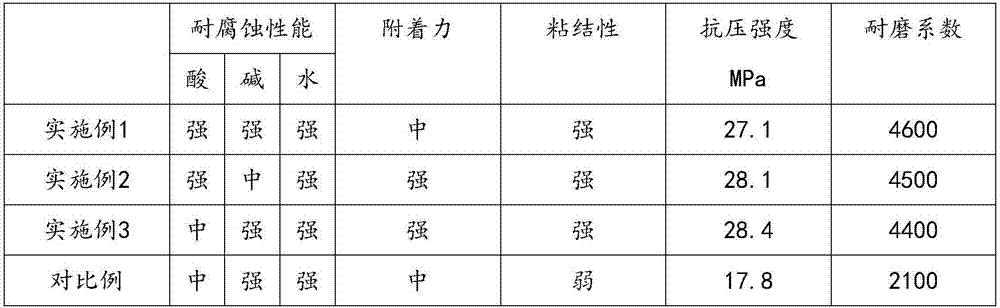

Examples

Embodiment 1

[0025] A coating used on the bearing of the rotor of a motor, characterized in that: it is made of the following materials by weight,

[0026] 11 parts of resin, 126 parts of nylon, 6 parts of modified activated carbon, 1 part of zinc stearate, 1 part of polyvinyl alcohol, 2 parts of polybutylene terephthalate, 2 parts of ethyl acrylate, 2 parts of diethylene triamine 1 part, 4 parts of vinyl trisilane, 1 part of aryl bis stearamide, 1 part of methyl acrylate, 8 parts of defoamer, 8 parts of anti-aging agent, 5 parts of biomass auxiliary materials, 20 parts of deionized water;

[0027] The resin is one of polyethylene resin, alkyd resin, phenolic epoxy resin, urea-formaldehyde resin, polyamide resin;

[0028] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0029] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypropylene ...

Embodiment 2

[0040] A coating used on the bearing of the rotor of a motor, characterized in that: it is made of the following materials by weight,

[0041] 17 parts of resin, 1210 parts of nylon, 11 parts of modified activated carbon, 4 parts of zinc stearate, 3 parts of polyvinyl alcohol, 4 parts of polybutylene terephthalate, 5 parts of ethyl acrylate, 6 parts of diethylene triamine 9 parts, 9 parts of vinyltrisilane, 4 parts of propylene bisstearamide, 5 parts of methyl acrylate, 15 parts of defoamer, 15 parts of anti-aging agent, 10 parts of biomass auxiliary materials, 27 parts of deionized water;

[0042] The resin is one of polyethylene resin, alkyd resin, phenolic epoxy resin, urea-formaldehyde resin, polyamide resin;

[0043] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0044] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene poly...

Embodiment 3

[0055] A coating used on the bearing of the rotor of a motor, characterized in that: it is made of the following materials by weight,

[0056] 14 parts of resin, 128 parts of nylon, 9 parts of modified activated carbon, 2 parts of zinc stearate, 2 parts of polyvinyl alcohol, 3 parts of polybutylene terephthalate, 4 parts of ethyl acrylate, 3 parts of diethylene triamine 5 parts, 5 parts of vinyl trisilane, 2 parts of aryl bis stearamide, 4 parts of methyl acrylate, 11 parts of defoamer, 12 parts of anti-aging agent, 8 parts of biomass auxiliary materials, 24 parts of deionized water;

[0057] The resin is one of polyethylene resin, alkyd resin, phenolic epoxy resin, urea-formaldehyde resin, polyamide resin;

[0058] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0059] The defoamer is one of emulsified silicone oil, higher alcohol fatty acid ester complex, polyoxyethylene polyoxypro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com