Manufacturing method of two-way heat exchange heater

A thermal heater and a manufacturing method technology, applied in the field of heater manufacturing, can solve the problems of not being able to realize two-way heat exchange heaters well, high production costs, and different production and manufacturing, and achieve short welding time, The effect of low leakage probability and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

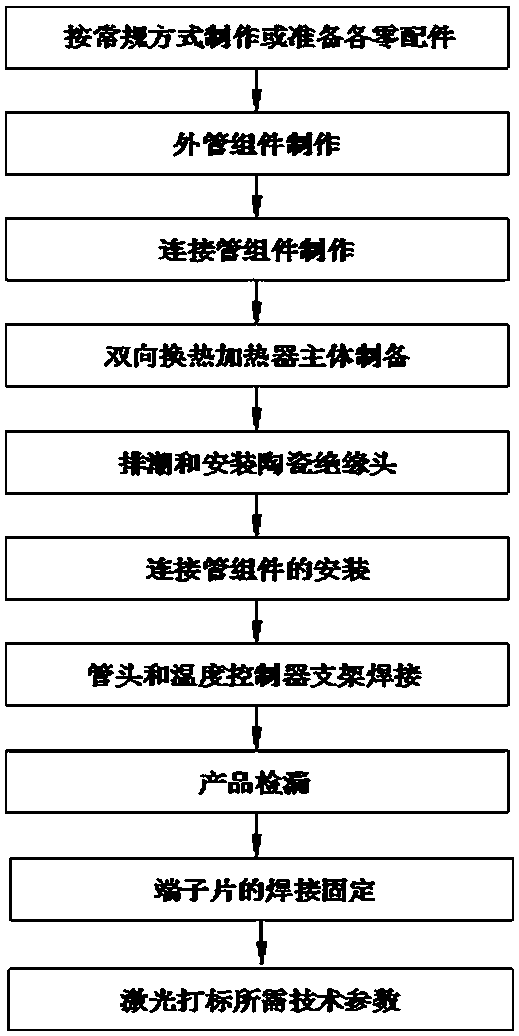

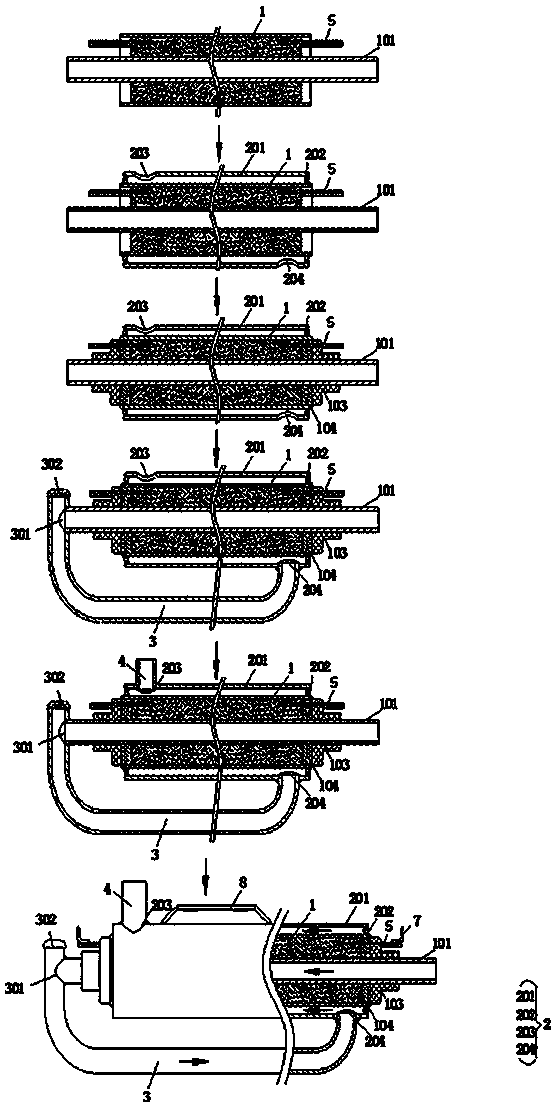

[0048] Such as figure 1 and figure 2 Shown, the manufacturing method of described two-way heat exchange heater, concrete steps are as follows:

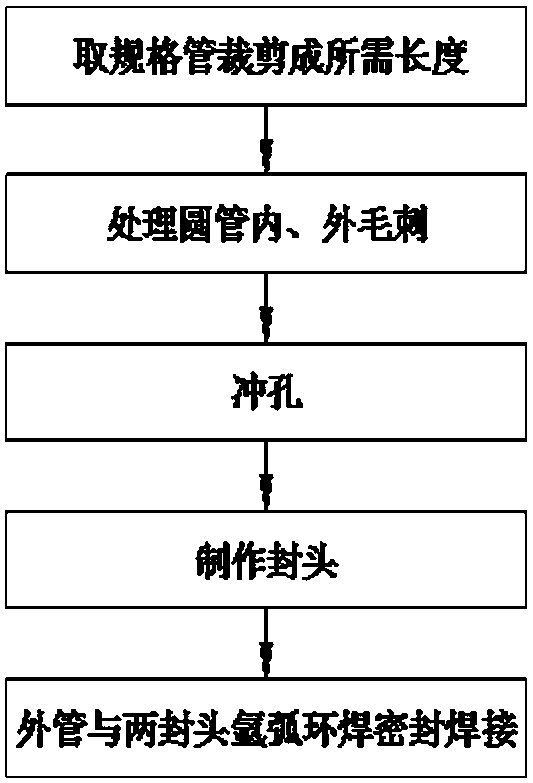

[0049] Step 1, such as image 3 and Figure 4 As shown, the outer tube assembly is made:

[0050] Step 1.1, making the outer tube: take the round tube of the required specification, cut it according to the required length, and after the inner and outer burrs are processed on the round tube, the two ends of the round tube are respectively punched by cold stamping to obtain through holes and Lower the through hole to get the outer tube 201;

[0051] Step 1.2, making the head: take the sheet material of the specification and punch it by blanking, and then use the forming die to make the head, or take the thick-walled tube of the specification and cold cut it into a blank of the required thickness, and then use the forming die to cold form The head 202 is made, the head 202 is U-shaped, and is recessed toward the middle end of the a...

Embodiment 2

[0066] Such as figure 1 and figure 2 Shown, the manufacturing method of described two-way heat exchange heater, concrete steps are as follows:

[0067] Step 1, such as image 3 and Figure 4 As shown, the outer tube assembly 2 is made:

[0068] Step 1.1, making the outer tube: take the round tube of the required specification, cut it according to the required length, and after the inner and outer burrs are processed on the round tube, the two ends of the round tube are respectively punched by cold stamping to obtain through holes and Lower the through hole to get the outer tube 201;

[0069] Step 1.2, making the head: take the sheet material of the specification and punch it by blanking, and then use the forming die to make the head, or take the thick-walled tube of the specification and cold cut it into a blank of the required thickness, and then use the forming die to cold form Made into a head 202;

[0070] Step 1.3, assembly of the outer tube and the head: insert th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com