Gas-liquid vibration damping device

A damping device, gas-liquid technology, applied in gas-liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problem of low boiling point of damping oil in hydraulic shock absorbers, affecting the service life of shock absorbers, and airtightness High performance requirements and other issues, to achieve the effect of low cylinder wall strength requirements, avoid severe vibration, and increase control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

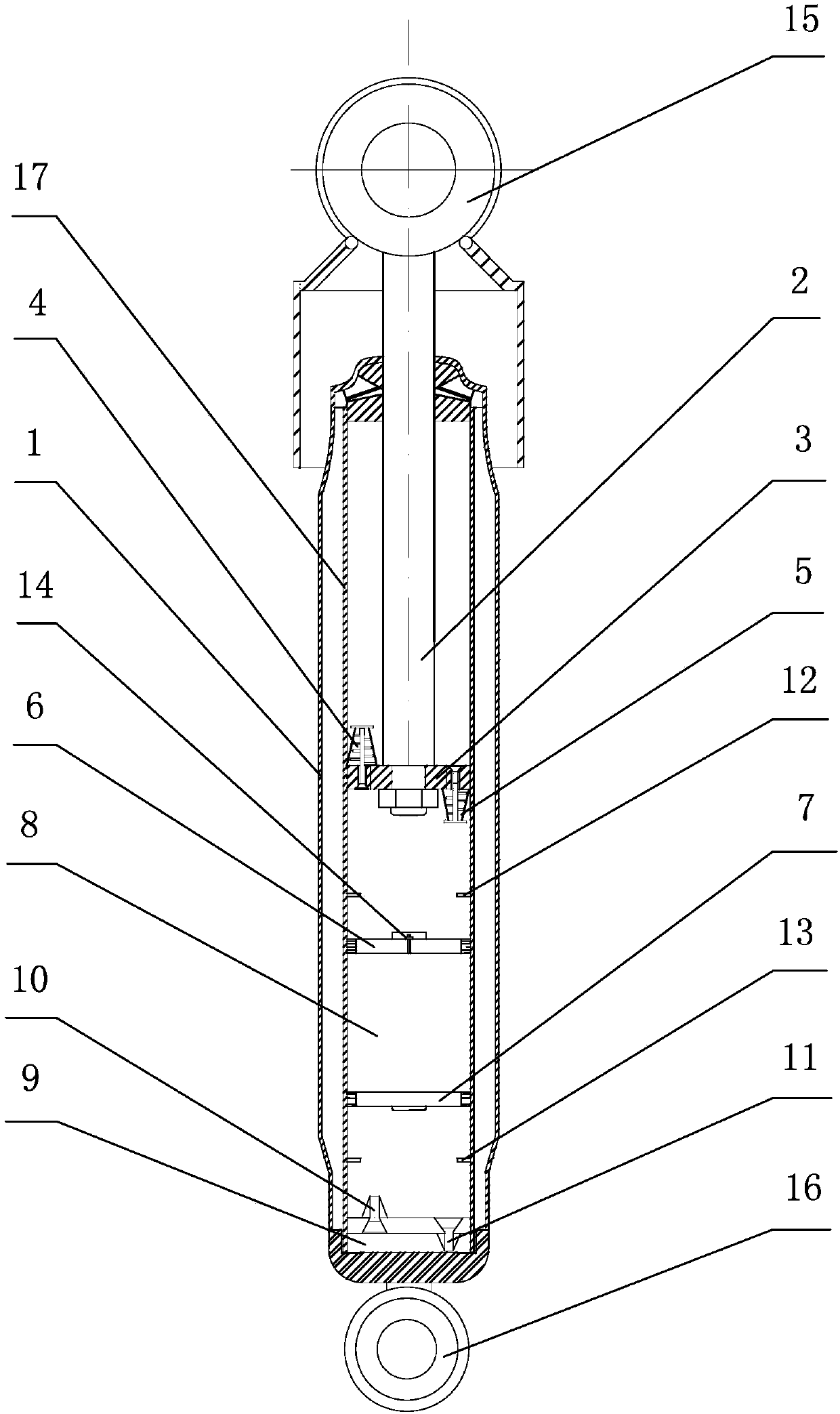

[0022] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] The gas-liquid vibration damping device of the present invention has a structure comprising a coaxial outer oil storage cylinder 1 and an inner oil storage cylinder 17, a piston rod 2 and a hydraulic piston 3, and the lower end of the oil cylinder rod 2 is connected to the inner oil storage cylinder 17. The oil pressure piston 3 and the upper end of the oil cylinder rod 2 are connected to the upper support 15 outside the inner and outer oil storage cylinders 17 and 1, and the oil pressure piston 3 divides the inner cavity of the inner oil storage cylinder 17 into an upper pressure chamber and a lower pressure chamber , the hydraulic piston 3 is provided with an expansion valve 4 and a compression valve 5; the lower pressure chamber includes an upper oil chamber, a floating air pressure chamber in the middle and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com