Air chute

A technology of air chute and air groove, which is applied in the direction of conveyor, transportation and packaging, and conveying bulk materials, which can solve the problems of material leakage and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

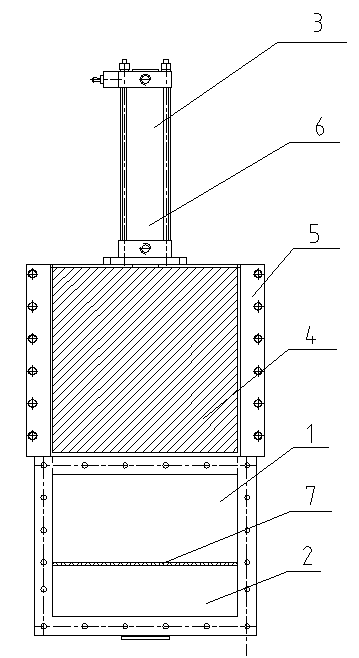

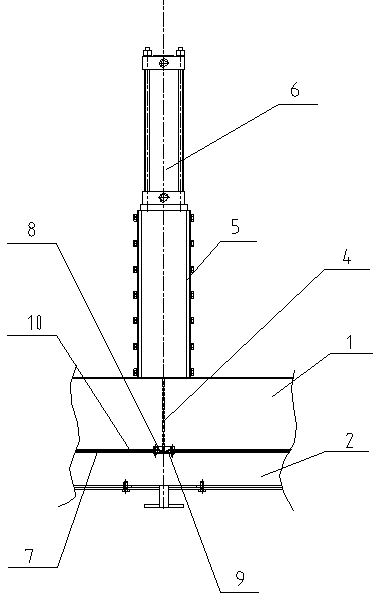

[0011] Such as figure 1 -shown in 4, comprising upper groove 1, lower groove 2 and material intercepting device 3, described upper groove 1 is a material groove, and lower groove 2 is an air groove, is provided with air-permeable layer 7 between upper groove 1 and lower groove 2 , A perforated plate 10 is also arranged above the air-permeable layer 7 .

[0012] The material intercepting device 3 includes a gate 4, a gate support frame 5 and a cylinder 6. The gate support frame 5 is placed on the upper end of the upper tank 1, and the gate 4 is installed in the gate support frame 5 so that it can move up and down. The cylinder 6 is used to drive the shutter 4 to move up and down to realize the opening and closing of the upper groove 1 .

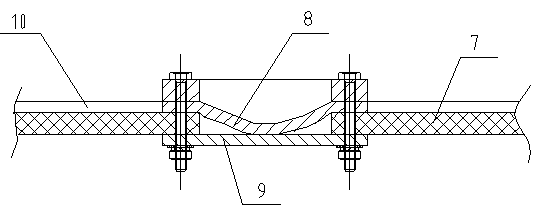

[0013] The air-permeable layer 7 on the same vertical plane as the flashboard 4 is provided with a transverse through groove, the upper end surface of the through groove is covered with a rubber layer 8 , and the lower end surface of the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com