Modularized damping driving wheel

A drive wheel, modularization technology, applied in the direction of motor vehicles, tracked vehicles, transportation and packaging, etc., can solve the problems of drive wheel tooth wear, insignificant effect, and tooth fracture, so as to reduce vibration transmission and facilitate tooth design Outline, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

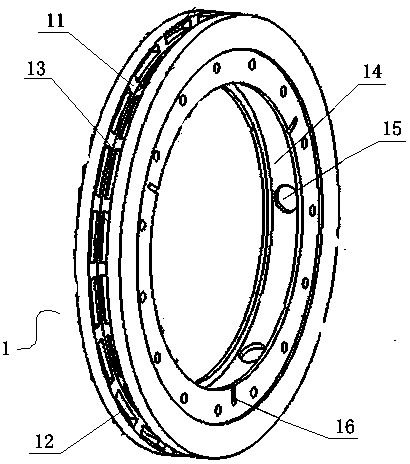

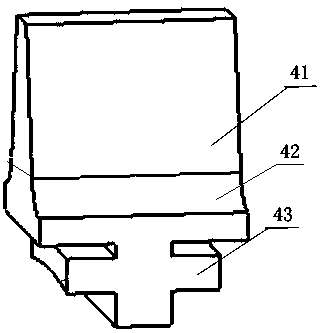

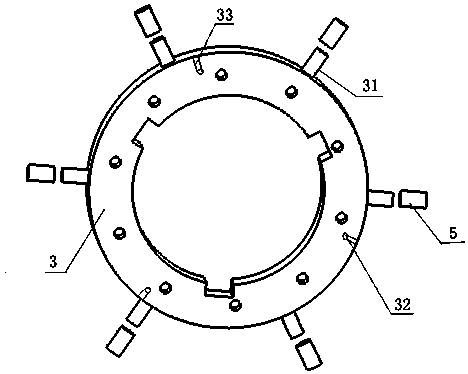

[0028] Figure 1-4 As shown, a modular damping drive wheel includes an outer wheel hub 1, an intermediate frame 2, an inner wheel 3, gear teeth 4, a damping tube 5, a U-shaped connector 6, and a quick-release connecting rod 7.

[0029] The arc surface of the outer ring of the outer wheel hub 1 is provided with a circumferential groove 11, the circumferential groove 11 is symmetrical along the neutral plane of the outer wheel hub, and a number of tooth installation positioning holes 12 are symmetrically arranged on the left and right ends of the circumferential groove 11, and the circumferential groove is arc-shaped. The surface is provided with a number of positioning grooves 13 for the tooth base, which are arranged in a circular array; the arc-shaped surface of the inner ring of the outer wheel hub is provided with a circular positioning groove 14 for the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com