Automatic prompting and correcting device for thermal battery lamination and prompting and correcting method thereof

An automatic prompting and error correction device technology, applied to primary batteries, primary battery manufacturing equipment, circuits, etc., can solve problems such as stacking order cannot be wrong, battery explosion, threat to user's life safety, etc., to reduce the probability of error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, the alarm 9 may be an audible alarm, and the audible alarm is installed at any position on the console 1 .

Embodiment 2

[0044] Embodiment 2, the alarm 9 may be a light alarm installed on the desktop of the console 1 .

[0045] In Embodiment 2, the alarm 9 is an audible and visual alarm, which is currently commonly used in the market. When used in the present invention, the situation that the operator ignores the alarm is avoided.

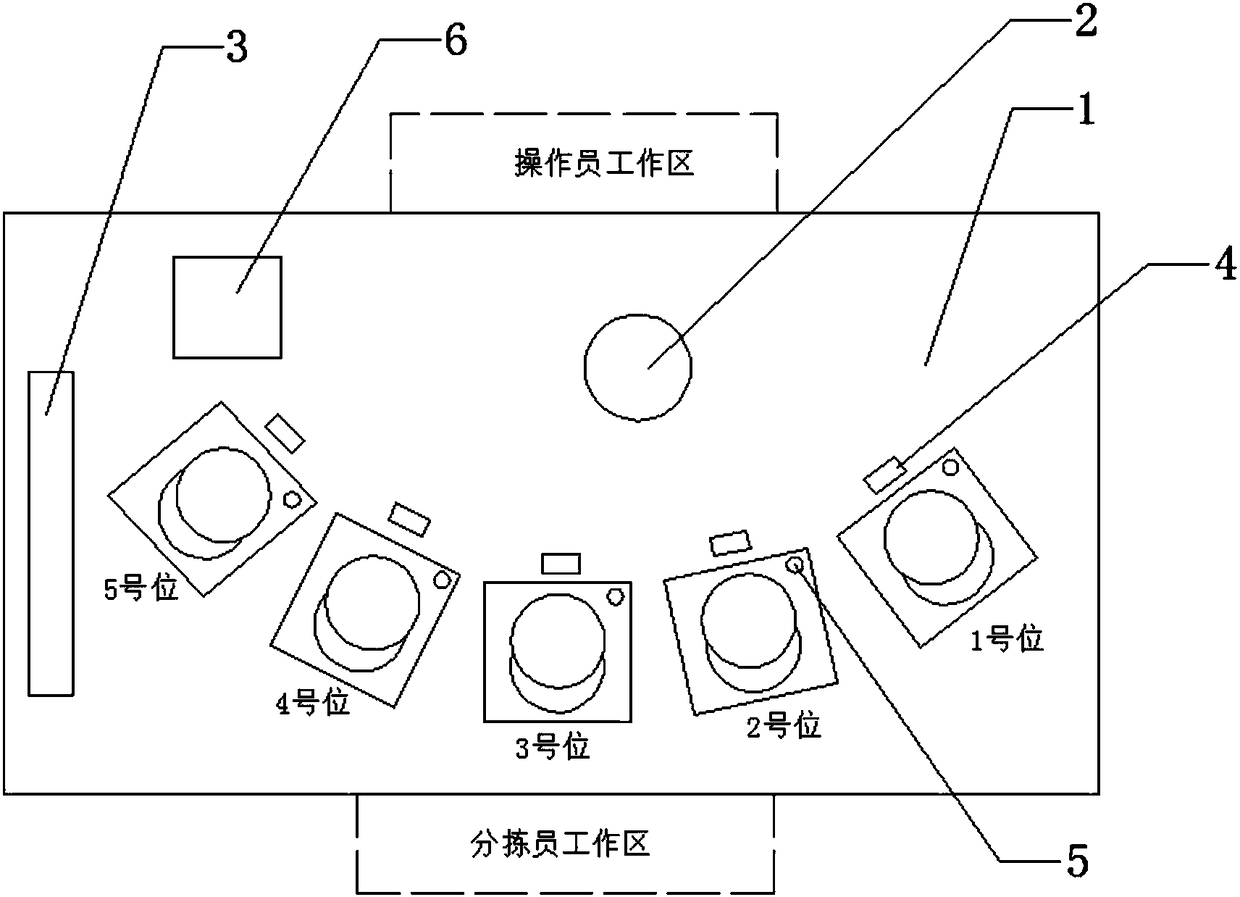

[0046] Such as Figure 5 As shown, a prompt error correction method of a thermal battery stack automatic prompt error correction device, its key lies in: comprising the following steps:

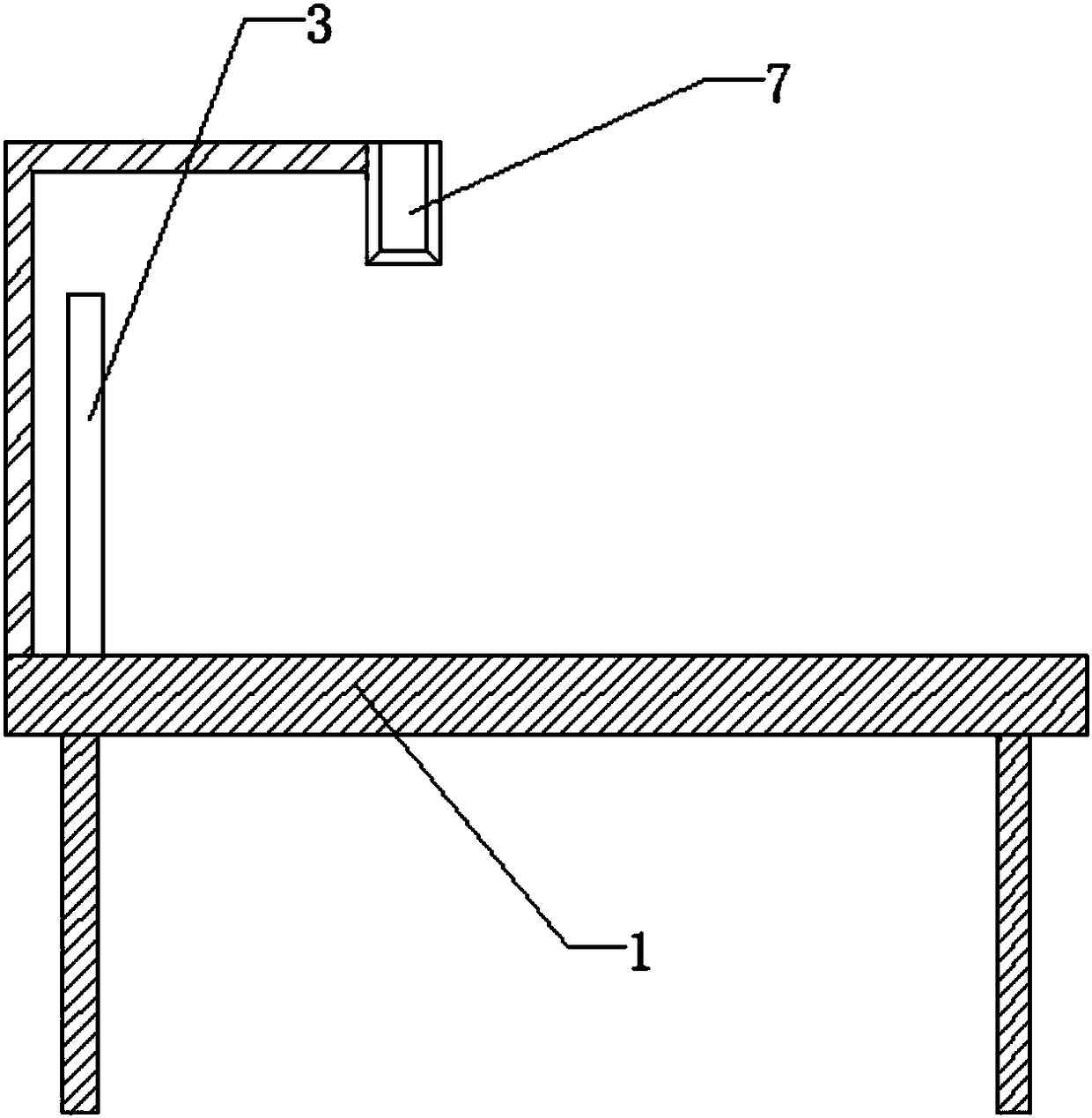

[0047] S1: The high-speed processor 8 starts the liquid crystal display 3 on the console 1 to dynamically display the sequential flow of battery stacking positions;

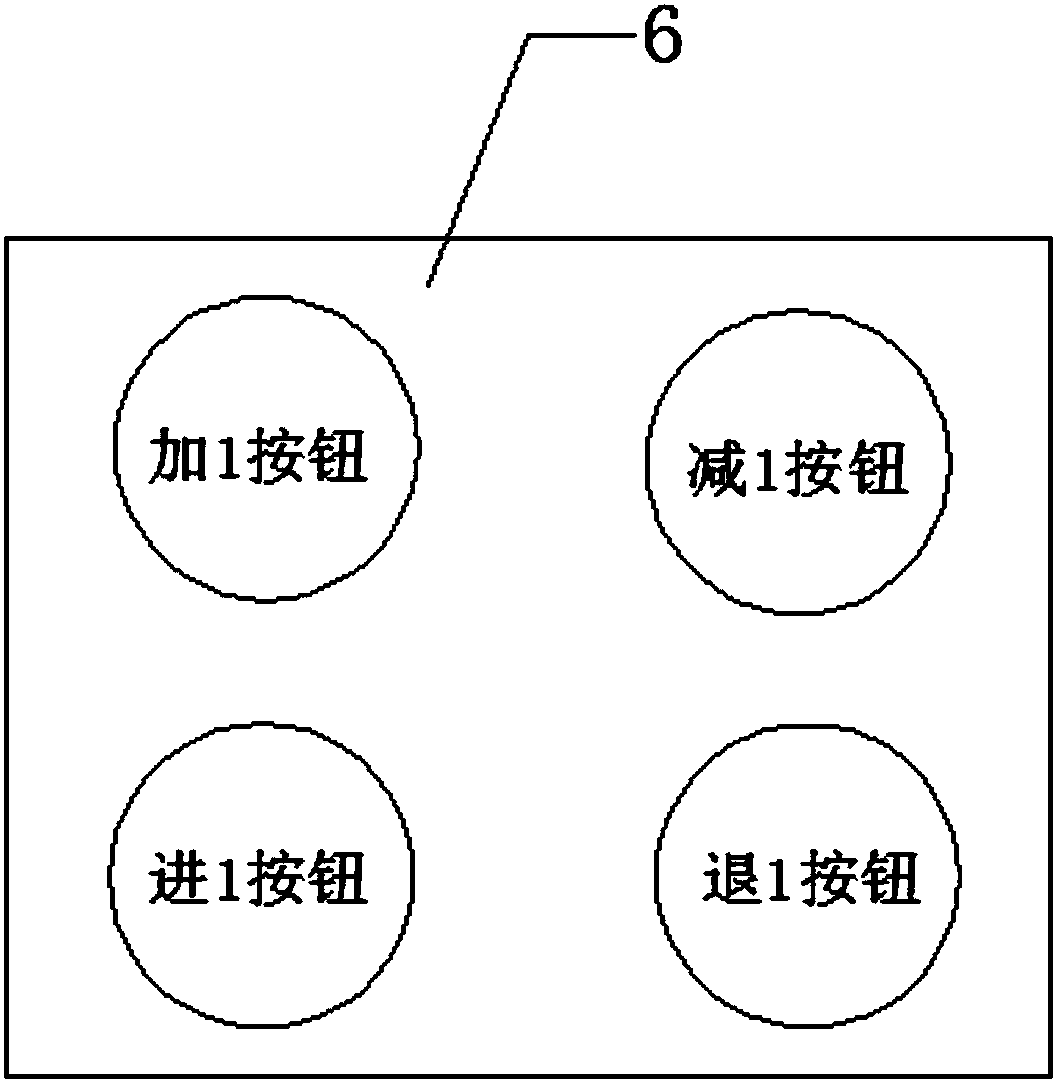

[0048] S2: The high-speed processor 8 controls the light-emitting indicator light 5 on the corresponding position for taking the film according to the sequence flow of battery stacking, and at the same time controls the liquid crystal display 3 to display the position of taking the film in this step, prompting the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com