Automatic polishing mechanism for connecting holes in end parts of hardware tool connecting rod

A technology of end connection and grinding mechanism, which is applied to machine tools, manufacturing tools, and metal processing equipment designed for grinding the rotating surface of workpieces. It can solve problems such as low efficiency, heavy manual labor, and manual grinding, and achieve high efficiency. , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

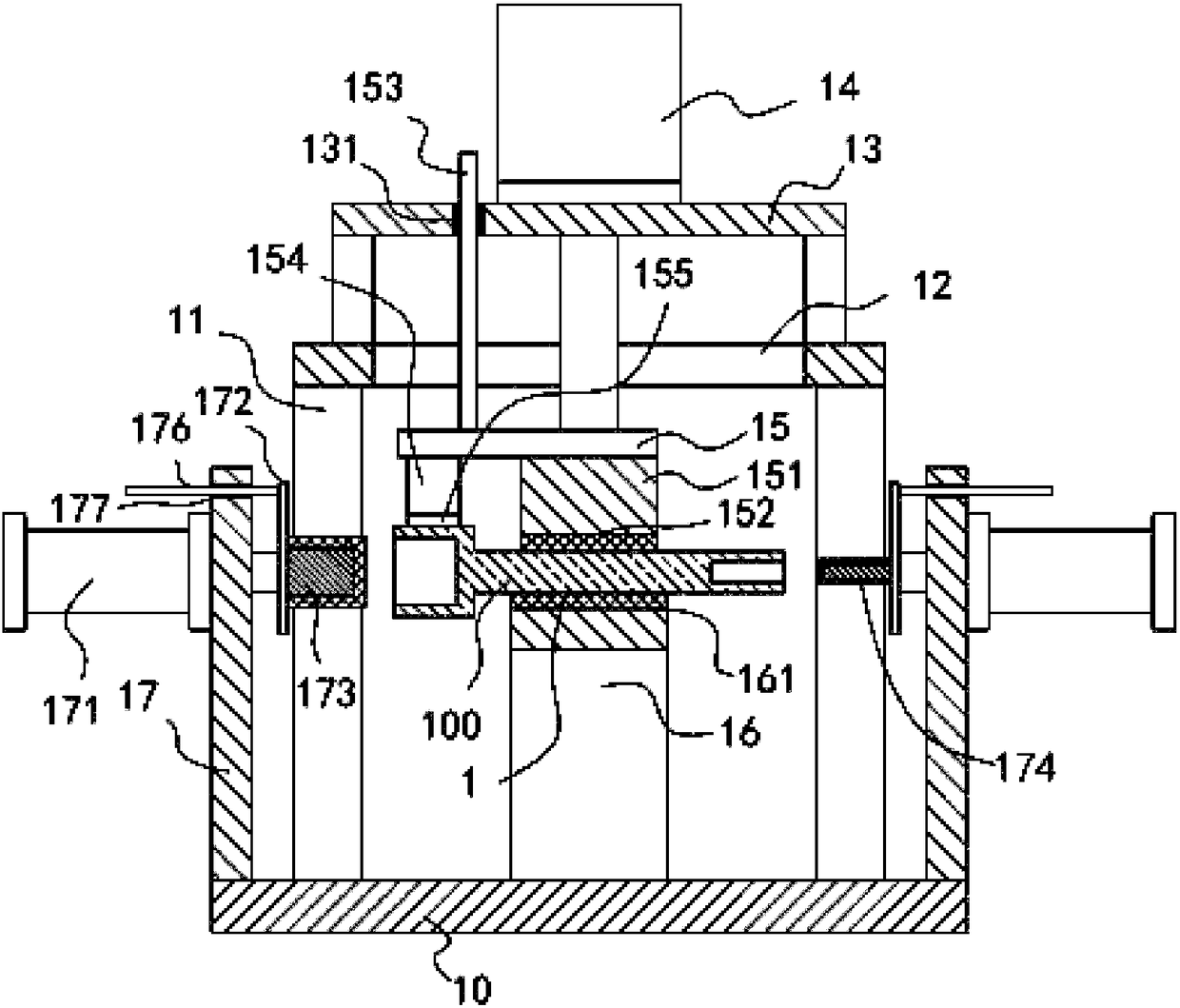

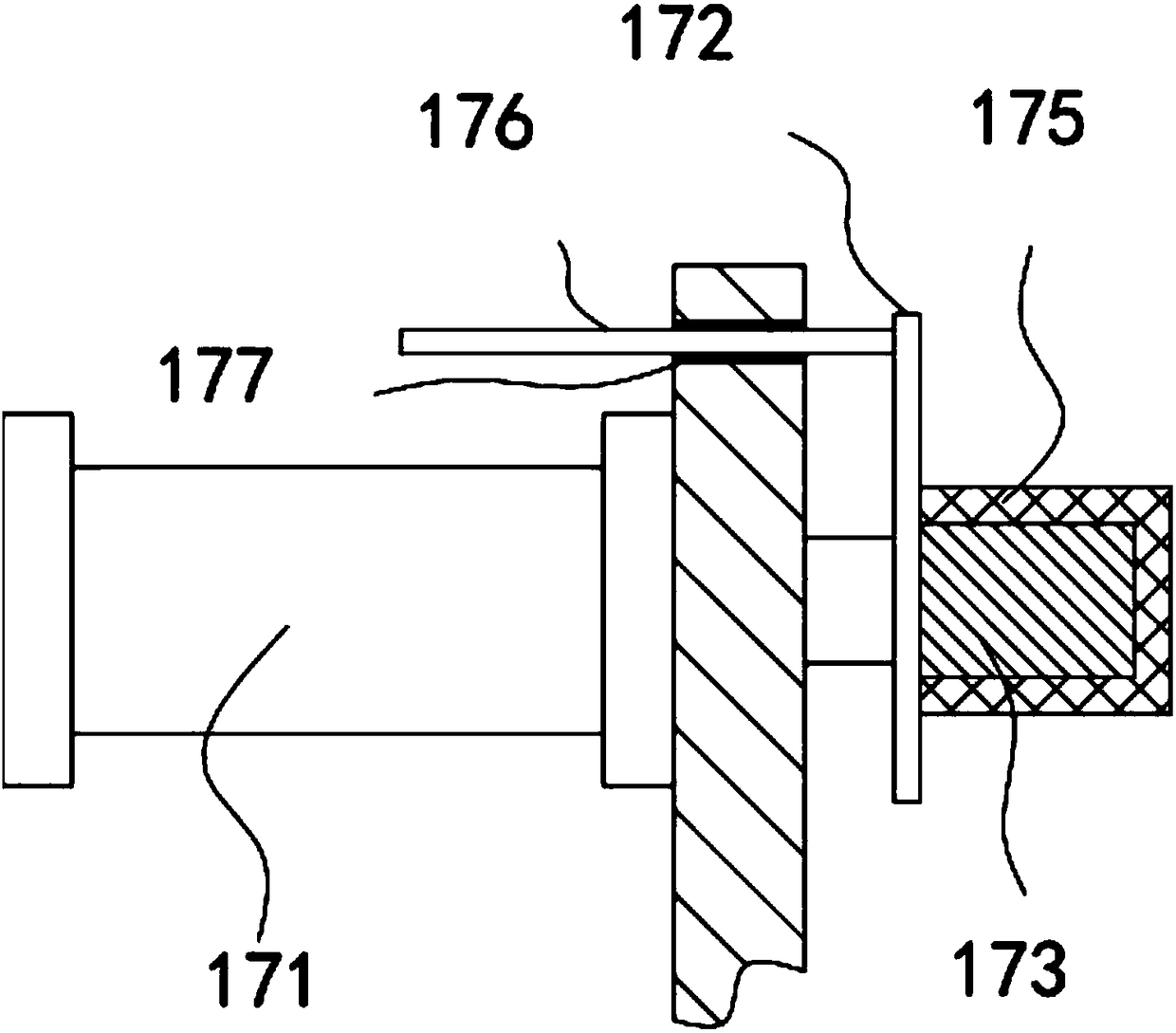

[0018] Example: see Figure 1 to Figure 2 As shown, an automatic grinding mechanism for the end connection hole of a hardware tool post includes a main base plate 10, an upper support frame 11 is fixed in the middle of the top surface of the main base plate 10, and the middle part of the top plate of the upper support frame 11 is formed with a long shaped through groove 12, the top surface of the top plate of the upper support frame 11 is fixed with an upper pneumatic support frame 13, and the top surface of the top plate of the upper pneumatic support frame 13 is fixed with a compression cylinder 14, and the push rod of the compression cylinder 14 passes through the upper pneumatic support frame. The top plate of support frame 13 is also fixed with lifting plate 15, and the push rod of pressing cylinder 14 is inserted and sleeved in elongated through groove 12, and the bottom surface of lifting plate 15 is fixed with upper pressing block 151, and the bottom surface of upper pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap