Automatic flip equipment

An automatic and equipment technology, applied in the directions of packaging, cutting and unsealing, transportation and packaging, etc., it can solve the problems of heavy workload and time-consuming manual rummaging, and achieve the effect of time-consuming, labor-saving and labor-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

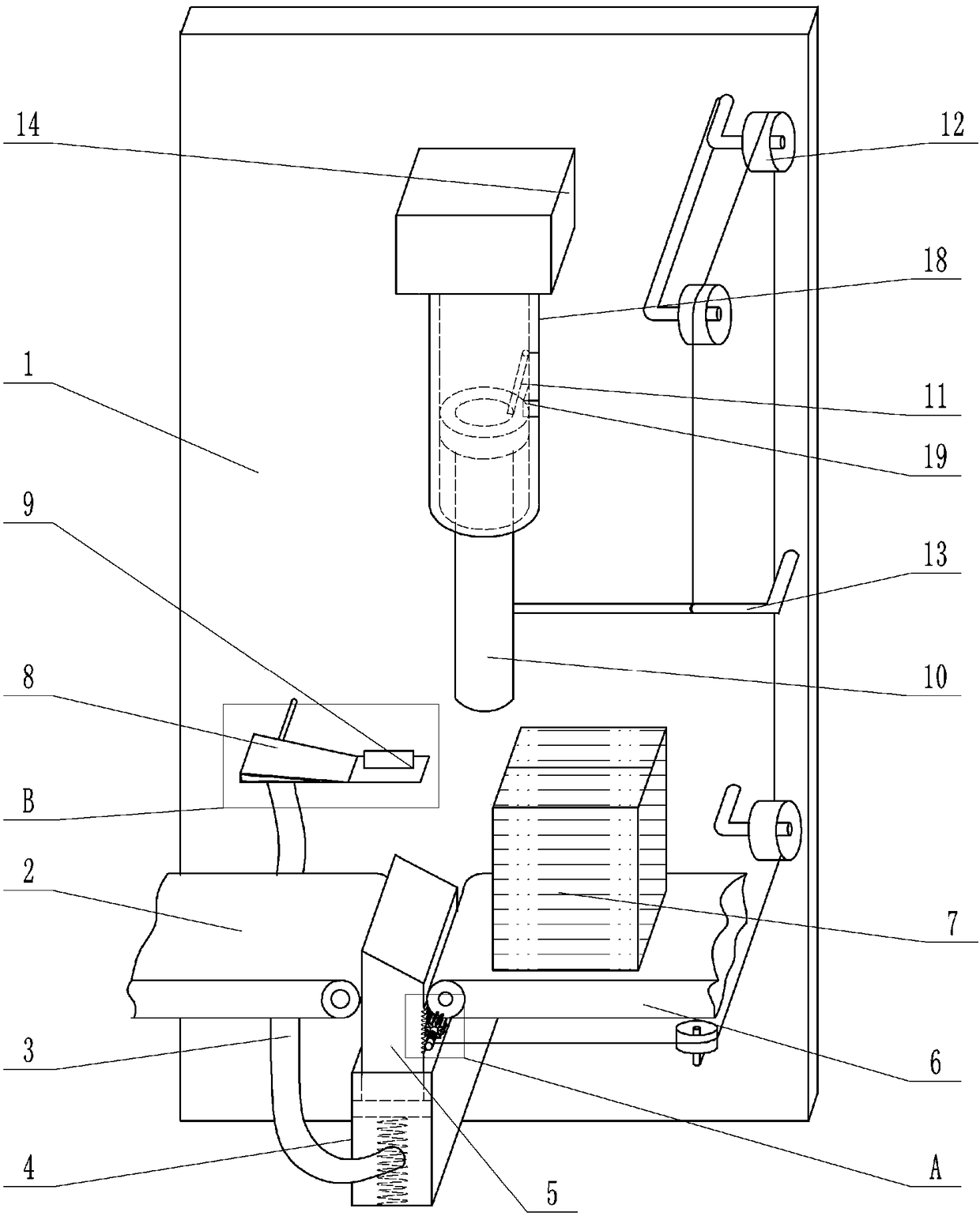

[0033] The embodiment is basically as attached figure 1 Shown: automatic flipping equipment, including: an installation frame 1, on which a transmission mechanism, a detection mechanism, a cutter flip assembly, a transmission assembly and an adsorption assembly are installed.

[0034] The conveying assembly is used to convey the packaging box 7 that needs to be flipped. The conveying assembly includes a first conveying assembly and a second conveying assembly. Both the first conveying assembly and the second conveying assembly are conveyor belts, which are respectively called the first conveying assembly in this embodiment. And the second transmission component is the first conveyor belt 2 and the second conveyor belt 6, and the transmission direction of the first conveyor belt 2 and the second conveyor belt 6 is from right to left.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com