Dust control device and method

A technology of a dust exhaust pipe and a dust hood is applied in the field of dust control devices, which can solve the problems of high equipment failure rate, environmental pollution, poor working environment, etc., and achieve the effects of reducing environmental pollution, ensuring smooth pipelines, and improving dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

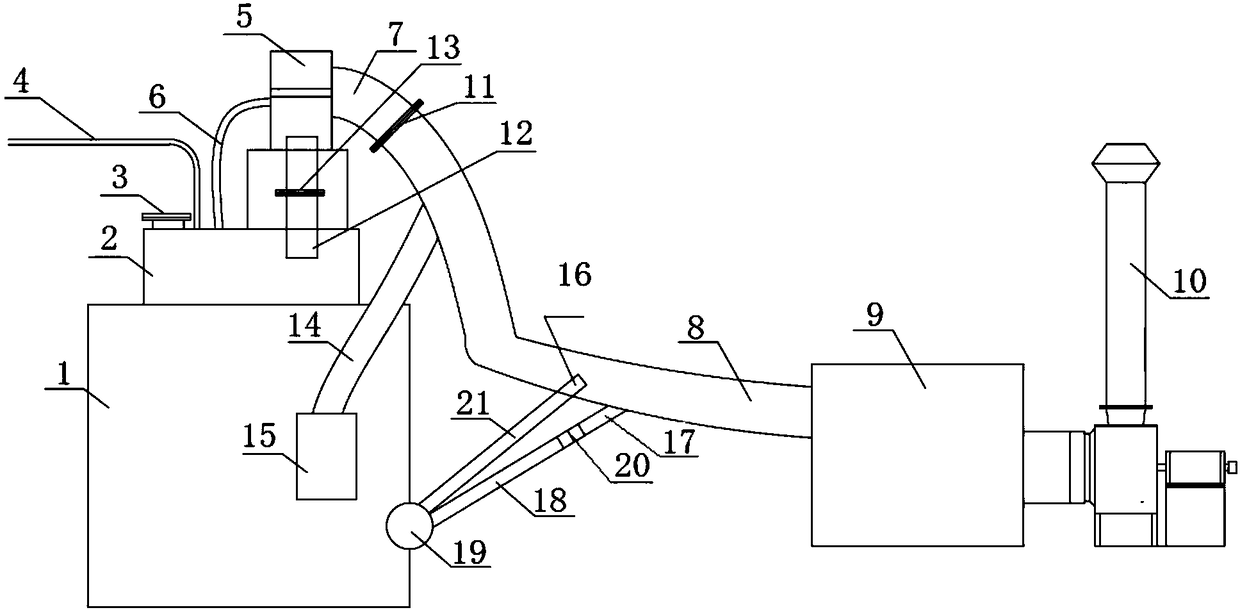

[0026] figure 1 Shows a schematic structural view of a dust control device according to a preferred embodiment of the present invention, the dust control device includes a storage box 2, a first dust control device 5, a second dust control device 9 and a dust collection hood 15, refer to figure 1 , The material storage box 2 is arranged in the material use place 1, and its inner cavity is closed. The storage box 2 is connected with the feeding pipe 4 for receiving and storing materials. The feed pipe 4 uses compressed air as a power source to transport the material into the storage box 2. When the material enters the storage box 2, it will generate relatively large dust under the impact of the air pressure. When the present invention is applied to the chiller, the material use place 1 is the chiller, the material storage box 2 is the sand storage box arranged on the chiller, and the feeding pipe 4 uses compressed air as a power source to transport the casting sand In the san...

Embodiment 2

[0033] The present invention also provides a fugitive dust control method, which adopts the above-mentioned dust control device, and when the feeding pipe 4 transports the material into the storage box 2, the dust generated in the storage box 2 passes through the first air inlet along with the airflow. The pipe 6 enters the first dust control device 5 for processing, and then the air flow passes through the first air outlet pipe 7 and the second air inlet pipe 8 and enters the second dust control device 9 for processing, and finally the air flow passes through the second air outlet pipe 10 discharge. After the feeding pipe 4 stops feeding, the fans of the first dust control device 5 and the second dust control device 9 can also be closed after a period of delay to improve the dust treatment effect. When the materials are used in the material use site 1, the dust generated by the material use site 1 enters the second air inlet pipe 8 through the dust collection cover 15 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap