A method for preparing hexagonal boron nitride nanosheets using molten alkali and ultrasonic stripping technology

A technology of hexagonal boron nitride and nanosheets, applied in the field of materials, can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] Typically, the preparation method comprises the following steps:

[0085] 1) Grinding and stirring sodium hydroxide and potassium hydroxide to form a mixed alkali, and then mixing the mixed alkali and hexagonal boron nitride powder to form a mixture;

[0086] 2) Transfer the prepared mixture to a polytetrafluoroethylene crucible and put it into an autoclave, react at a high temperature for 1-5 hours, and then cool naturally to room temperature;

[0087] 3) Disperse the obtained reactants in deionized water for ultrasonic stripping, then filter the obtained product, wash with deionized water, redisperse in deionized water, and then centrifuge, collect the upper dispersion liquid and dry it to obtain the hexagonal nitriding Boron nanosheets;

[0088] 4) Disperse the centrifugal precipitate obtained in the above steps in deionized water, add sodium hydroxide and potassium hydroxide for ultrasonic stripping, then filter the obtained product, wash with deionized water, redi...

Embodiment 1

[0109] (1) Weigh 2.5g of sodium hydroxide and potassium hydroxide respectively, grind and mix well to form a mixed alkali, and then mix the mixed alkali with 5g of hexagonal boron nitride powder (about 3-18um in particle size).

[0110] (2) The obtained mixture was transferred to a polytetrafluoroethylene crucible and placed in an autoclave, reacted at 180° C. for 1 h, and then cooled naturally to room temperature.

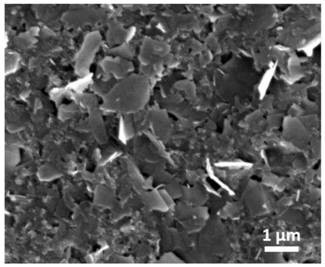

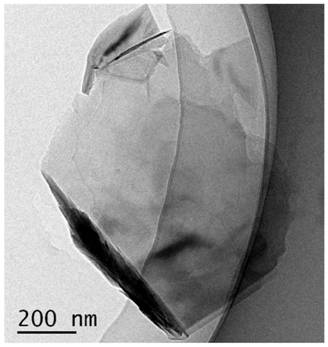

[0111] (3) Disperse the reaction product in the reaction kettle in deionized water, and perform 160W ultrasonic stripping on the obtained mixed solution for 1 hour. The ionic water is washed several times in order to wash away the lye and borate (such as the mixture of sodium borate and potassium borate). After washing the product, redisperse the obtained product in deionized water and then centrifuge (centrifugation speed is 1700 rpm, centrifugation time is 30min), collect the upper layer dispersion liquid and dry (drying treatment temperature is 80°C, treatment ...

Embodiment 2

[0124] With embodiment 1, difference is: the add-on of sodium hydroxide and potassium hydroxide is respectively 3g and 2g in the step (1) and (4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com