Toilet glaze spraying work bench

A toilet and workbench technology, applied in the field of sanitary ware production, can solve the problems of poor glaze spraying effect, unfavorable glaze mist outflow, uneven glaze spraying of toilet sewer pipes, etc., and achieves good glaze effect, high degree of automation, and oil layer. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

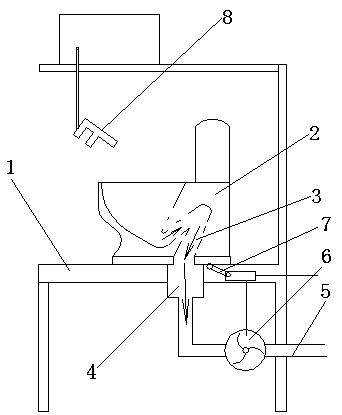

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, a toilet glazing workbench includes a table top 1 with a glaze spraying device 8 on the table. The toilet is placed on the table when the glaze is sprayed, and the toilet 2 can be glazed by the glaze spraying device. The toilet There is a sewer pipe 3 below; the feature is that there is a through hole 4 matching the toilet sewer pipe on the table.

[0014] When spraying glaze for the toilet, place the toilet on the countertop, and place the outlet of the sewer pipe of the toilet with the through hole, so that the sewer pipe is in an unobstructed state, and the glaze mist sprayed on the sewer pipe is in a flowable state. It can flow out smoothly, so that the glaze layer formed on the side wall of the sewer pipe is just more uniform, and the purpose of the present invention is achieved. The direction of the arrow in the figure is the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com