Effect glaze for building ceramic surface decoration and application method thereof

A technology for building ceramics and surface decoration, applied in the field of building ceramics, can solve the problems of increasing the processing cost of the manufacturer, the wear resistance is not very high, the decoration effect is poor, etc., and achieves good antifouling performance, good glaze effect, and glazing amount. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of specific frit comprises the following steps:

[0028] (1) Take the following component raw materials by weight: SiO 2 55 parts, Al 2 o 3 2.5 parts, CaO 12 parts, R 2 2 parts of O, 1 part of MgO, 6 parts of ZnO, B 2 o 3 0.5 parts, where R 2 O is Na 2 O, K 2 O. Li 2 O a mixture of the three;

[0029] (2) Mix the weighed formula raw materials evenly in proportion; (3) Melt the mixed raw materials into a uniform glass melt at 1560-1580 ° C; (4) pour the obtained glass melt into water, water quench It becomes slag, then dehydrated and dried to obtain the finished frit, which can be packaged.

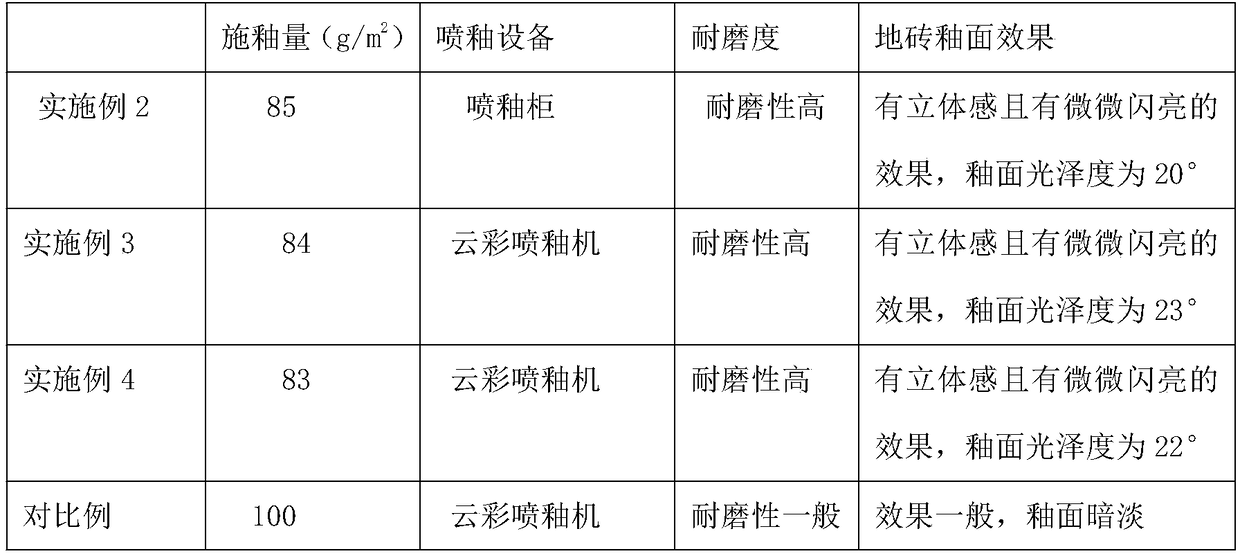

Embodiment 2

[0031] An effect glaze for floor tile surface decoration, comprising the following components in parts by weight: 72 parts of frit prepared in Example 1, 12 parts of calcined soil, 12 parts of kaolin, 3 parts of potassium feldspar, 0.12 parts of carboxycellulose Parts, 0.34 parts of sodium tripolyphosphate, 34 parts of water,

[0032] The method of use includes the following steps:

[0033] S1, preparation of effect glaze slurry: add the component raw materials of the above formula into the ball mill, and after ball milling for 15 hours, the slurry obtained from the grinding passes through a 325 sieve to sieve the remaining 0.3-0.5%, and adjust the specific gravity to 1.40g / cm 3 , after iron removal treatment, the effect glaze slurry is obtained;

[0034] S2, spraying of effect glaze: the effect glaze slurry prepared in S1 is sprayed on the glazed surface of floor tiles that have been treated with surface glaze and spray printed patterns in a spray glaze cabinet with a comp...

Embodiment 3

[0038] An effect glaze for floor tile surface decoration, comprising the following components in parts by weight: 74 parts of frit prepared in Example 1, 11 parts of calcined soil, 13 parts of kaolin, 3 parts of potassium feldspar, and 0.14 parts of carboxycellulose Parts, 0.34 parts of sodium tripolyphosphate, 35 parts of water,

[0039] The method of use includes the following steps:

[0040] S1, preparation of effect glaze slurry: add the component raw materials of the above formula into the ball mill, and after ball milling for 14 hours, the slurry obtained after the grinding is passed through a 325 sieve, and the remaining 0.3-0.5% is sieved, and the specific gravity is adjusted to 1.45g / cm 3 , after iron removal treatment, the effect glaze slurry is obtained;

[0041] S2, use the effect glaze slurry prepared in S1 to use the cloud glaze spraying machine to evenly spray the effect glaze on the glazed surface of the floor tiles that have been treated with surface glaze ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com