A kind of preparation method of pet wood-plastic composite material

A technology of wood-plastic composite materials and mixed materials, which is applied in the preparation of wood-plastic composite materials and PET wood-plastic composite materials, and can solve the problems of limiting the production and application of PET wood-plastic composite materials and high melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

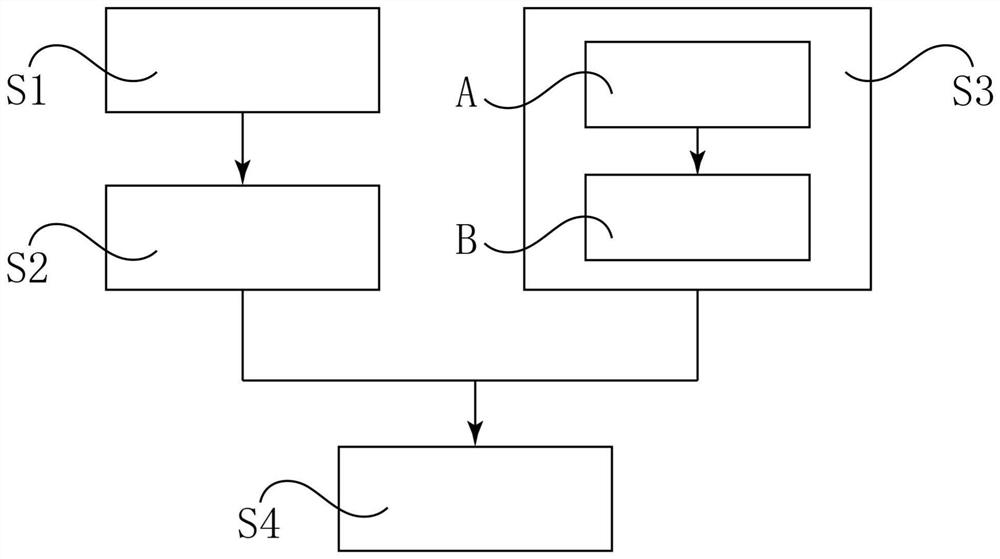

Method used

Image

Examples

Embodiment 1

[0038] The modified wood powder is prepared by the following method: take straw powder with a particle size of 170 μm to 190 μm, heat treatment at 100 ° C and dry, then extract with acetone, and dry for later use; add water to dilute the thermosetting phenolic resin, add the above-mentioned wood powder, and the weight of the wood powder It is 0.8 times the weight of the thermosetting phenolic resin, ultrasonicated at room temperature for 30 minutes in an ultrasonic cleaner, and then centrifugally filtered, the centrifugal speed is 1200 r / min, the centrifugation time is 5 minutes, and the filtrate after centrifugation is heat-treated at 128 ° C for 45 minutes to obtain modified wood. pink. Take three parts of the obtained modified wood powder, in a high-purity nitrogen atmosphere of 100 mL / min, heat up to 250 ° C, 350 ° C, and 600 ° C, respectively, and keep the temperature for 30 minutes for pyrolysis. , 64.1%.

Embodiment 2

[0040] The modified wood powder was prepared by the following method: take poplar wood powder with a particle size of 170 μm to 190 μm, heat treatment at 105 ° C and dry, then extract with acetone, and dry for later use; add water to dilute the thermosetting phenolic resin, add the above-mentioned wood powder, wood powder The weight is 0.8 times the weight of the thermosetting phenolic resin. Ultrasonic for 30min at room temperature in an ultrasonic cleaner, then centrifugal filtration, centrifugal speed 1200r / min, centrifugation time 5min, the filtrate after centrifugation is modified by heat treatment at 128°C for 45min Wood flour. Take three parts of the obtained modified wood powder, in a high-purity nitrogen atmosphere of 100 mL / min, heat up to 250 ° C, 350 ° C, 600 ° C, respectively, and keep the temperature for 30 minutes for pyrolysis, and detect the residual carbon rate, which are 87.5% and 76.1%, respectively. , 63.5%.

Embodiment 3

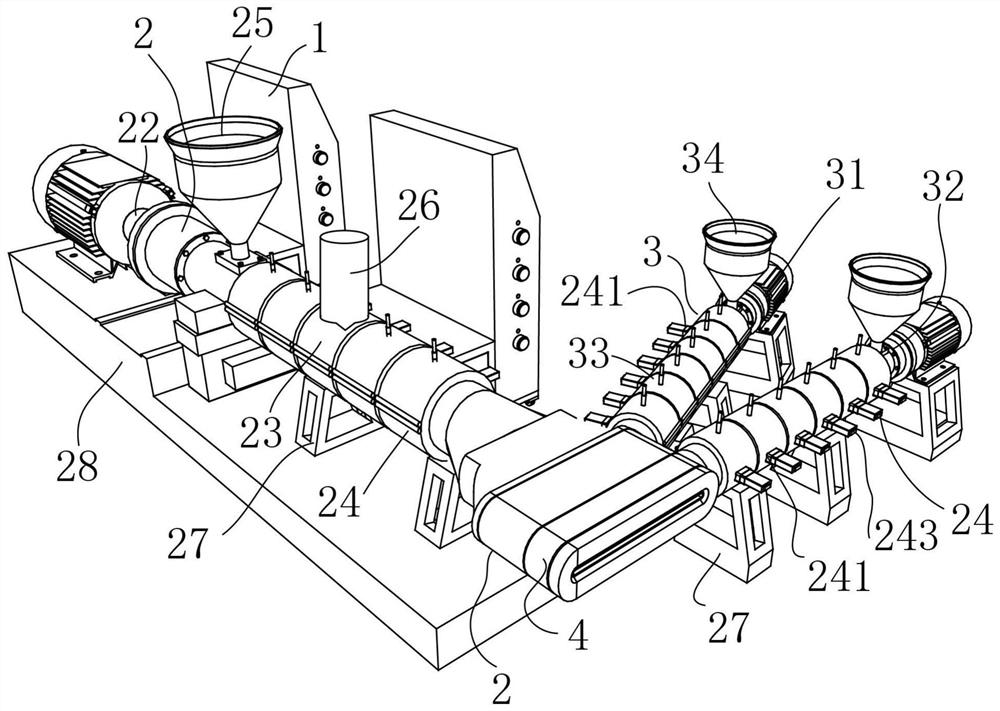

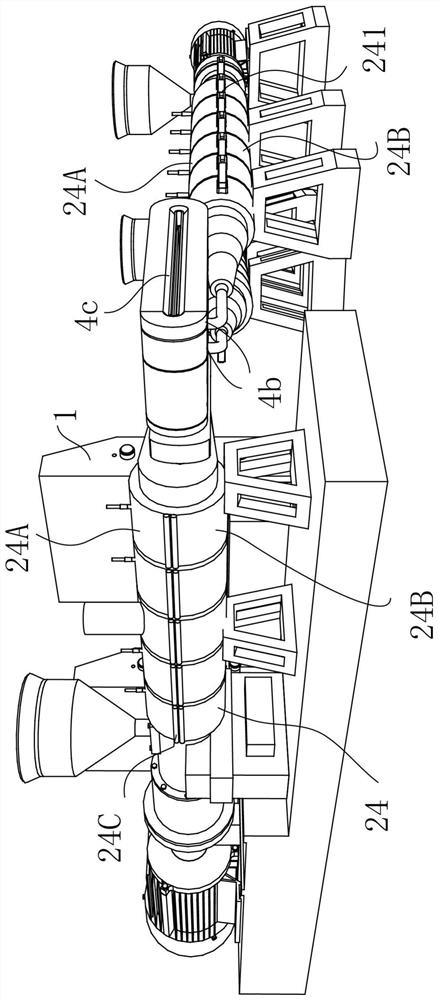

[0042] The PET wood-plastic composite material of the present invention is prepared by the following method: the PET resin is dried at 125° C. for 4 hours to form a foamed raw material, and the obtained foamed raw material is uniformly mixed with a nucleating agent to obtain a mixture for use; Example 1 The obtained modified wood powder, coupling agent and sodium carboxymethyl cellulose were treated in a high-speed mixer for 35 minutes, and mixed with the aforementioned mixture at 73 ° C to obtain a mixed material, and then a foaming agent and a plasticizer were added, and the mixture was uniformly mixed. , kneading in a two-roll mill, the kneading temperature is 248 ℃, the kneaded material is cooled down to obtain a composite material sheet, and then mixed with the PET foam sheet at a temperature of 250 ℃ and a pressure of 9 MPa. Hot press molding, in which the PET foam sheet is in the middle layer, and the material of the composite material is in the upper and lower layers. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com