Braiding core rod transfer device of net weaving equipment

A transmission device and braided core technology, applied in the direction of braided fabrics, textiles, and papermaking, can solve problems such as low efficiency, unstable quality of braided fabrics, and inability to liberate labor, so as to improve firmness, accelerate dispersion of vibration, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

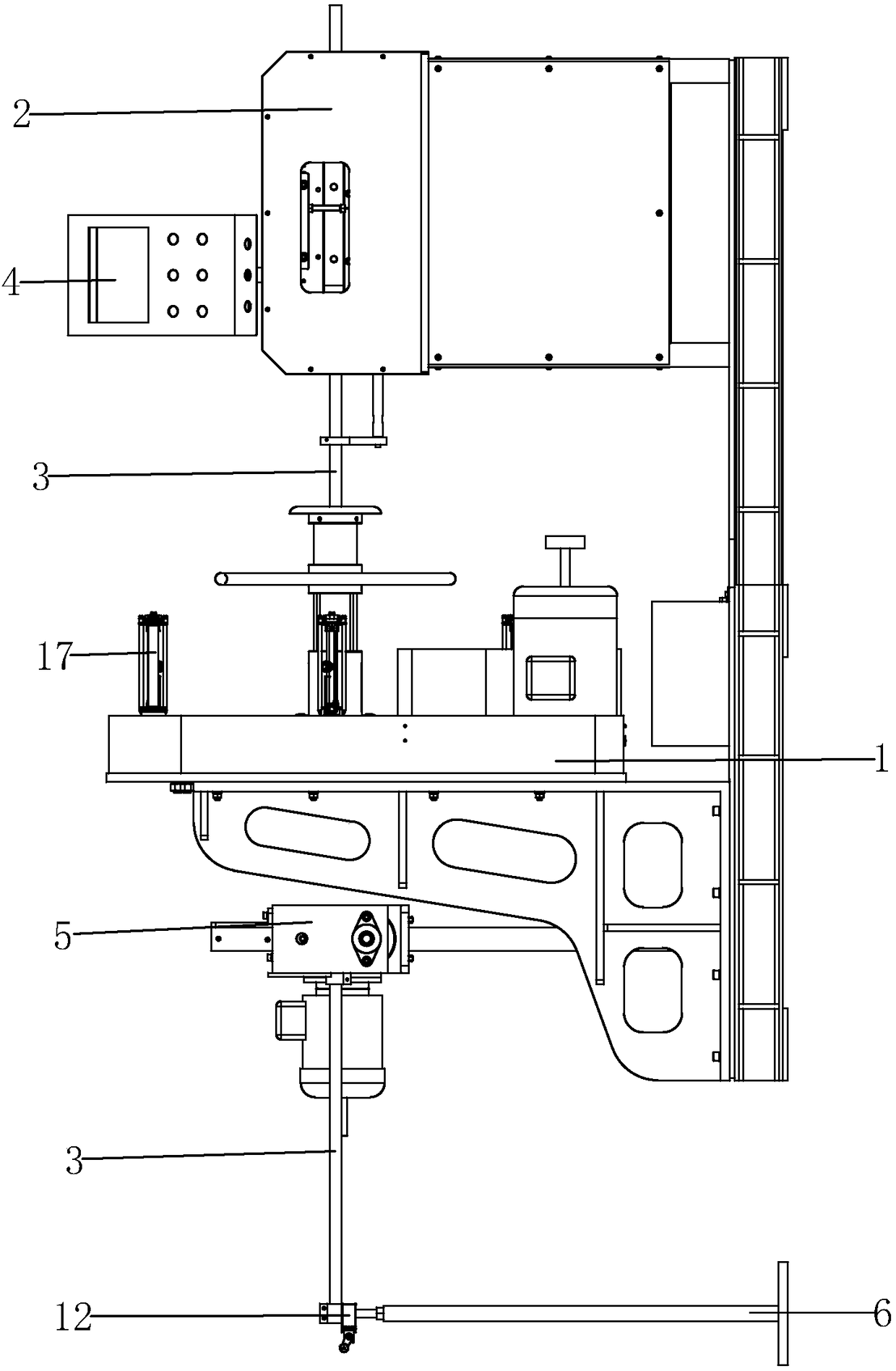

[0020] Such as Figure 1 to Figure 3 As shown, it is the braiding mandrel transfer device of the net cover equipment of the present invention, including a braiding host 1, a braiding front tractor 2, a braiding mandrel 3, an electrical control system 4, a braiding mandrel rear traction machine 5 and a braiding mandrel support frame 6. The electrical control system 4 controls the start and stop of the braiding host 1 and the tractor before weaving 2, and the braiding mandrel 3 passes through the braiding mandrel support frame 6, the tractor 5 after the braiding mandrel, the braiding host 1 and the tractor before weaving 2.

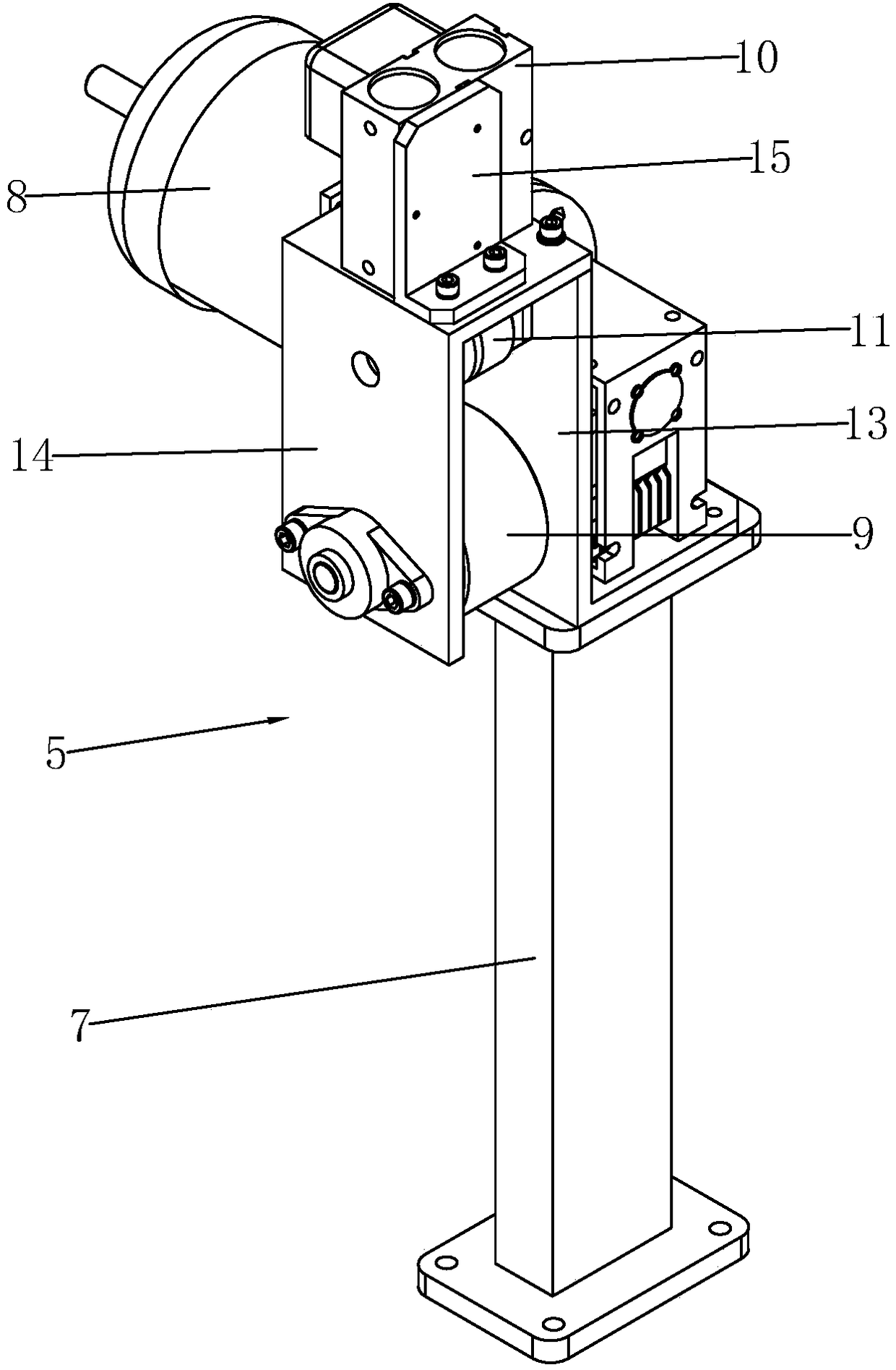

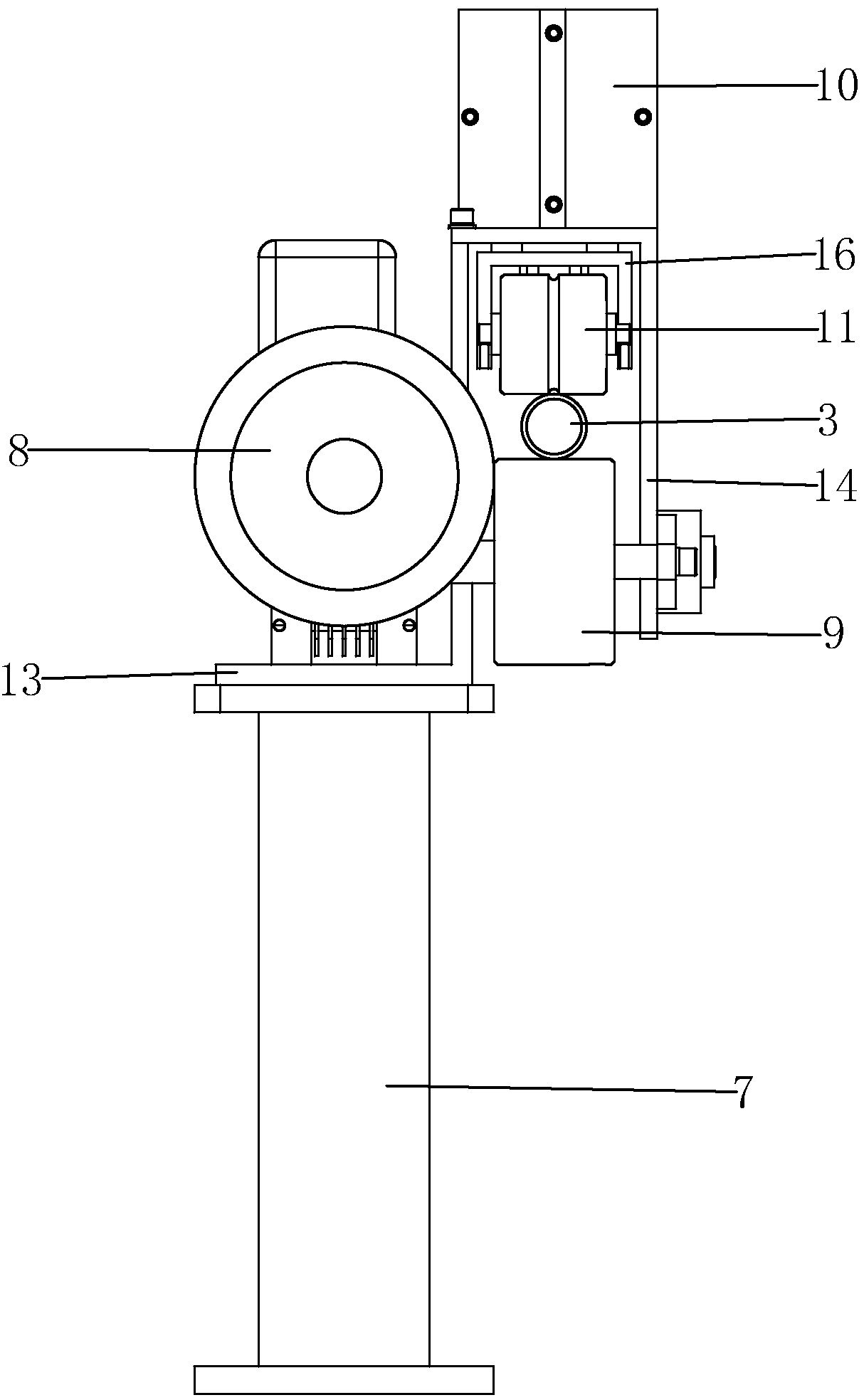

[0021] After weaving the mandrel, the tractor 5 includes a support seat 7 and a clamping traction mechanism. The clamping traction mechanism includes a reduction motor 8, a traction driving wheel 9, a cylinder 10 and a driven wheel 11. The reduction motor 8 is connected to the traction driving wheel 9, and the cylinder 10 is connected to the The driven whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com